Large Taper, Tiny Tool

An auxiliary electric spindle enables this shop to perform intricate cuts with machines designed for heavy hogging.

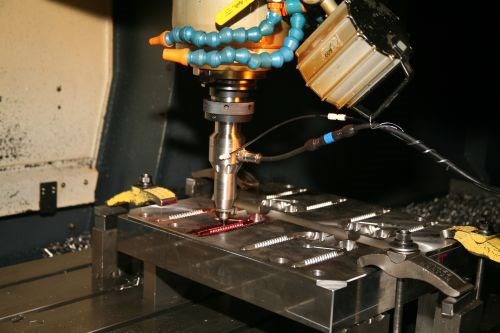

With a straight shank, the electric spindle can be fitted to any of the shop's 40- or 50-taper machining centers.

As a specialist in rubber molds, Ron Al Mold and Machine is concerned mostly with heavy-duty cutting. Thus, it’s no surprise that the shop is stocked with mostly 40- and 50-taper machining centers. Yet, nearly every part contains at least one small feature—a tear trim, an engraving—that just isn’t well-suited for these machines. Given the realities of business, the shop can’t prioritize an investment in a new machining center just for these features. However, pushing 6,000-rpm spindles to the limit, slowing feed rates to a crawl and losing tools in the process isn’t a great option either.

The shop found a solution in an auxiliary spindle from NSK America that provides speeds ranging to 50,000-rpm—more than fast enough for the shop’s smallest tools and most intricate work. As an added benefit, the spindle is completely self-powered. Learn more here.

.jpg;maxWidth=300;quality=90)