How to Choose the Right Drill

Technical and business considerations when selecting a drill for mold machining.

Drilling in mold manufacturing often differs from conventional drilling with respect to several key factors. For one thing, there is a greater frequency of contoured drilling surfaces. For another, the industry employs tougher materials than are typically encountered in general machining. Successfully dealing with these conditions requires an application-specific machining strategy.

Contoured surfaces or interrupted cuts can present problems whether you are using an indexable drill, a replaceable point drill, a solid carbide drill or even a high-speed steel (HSS) drill. That’s because the more irregular the surface, the greater chance of deflection.

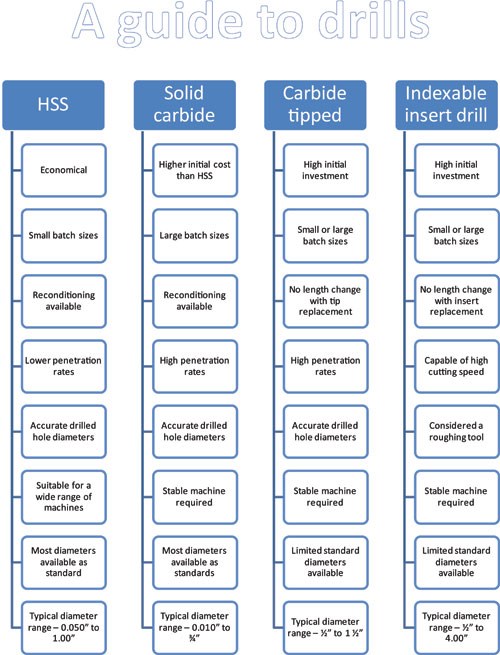

Before looking at deflection, though, let’s consider which type of drill to use. The answer depends on both technical and business considerations.

Holes 0.5 in. diameter and under with depths up to 70xD are best suited for solid carbide. When confronted with larger diameter holes, indexable drills often provide the most efficient solution for holes up to 5xD. Above that, up to 10xD, replaceable tip drills are the prime candidates. For all of these applications coolant-thru drills are recommended.

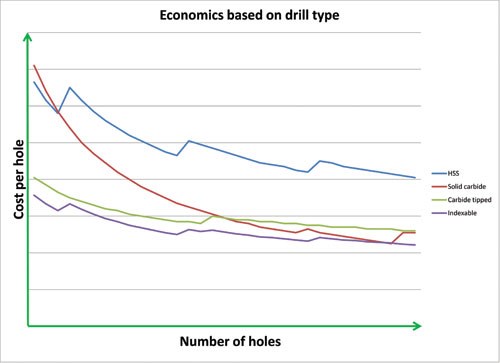

There is also the economics of the application to be considered. For very low volumes where cycle time and cost per hole are not critical, an economical HSS drill might suffice. For higher volumes, a solid carbide drill could be advantageous because even though it is more expensive, it can run at higher speeds with higher cutting parameters. This provides lower cost per hole and higher throughput.

However, for holes from 0.5 in. diameter and up, and for depths up to 5xD, indexable insert drills will typically provide the best cycle time and cost per hole. This is because they bring less cutting tool material into contact with the hole wall, so there is less friction, allowing higher cutting speed. They also have an advantage, since unlike HSS or solid carbide drills, reconditioning is not necessary. The tradeoff is in precision (i.e., hole location and diameter tolerance). That’s because indexable drills are more prone to deflection than solid carbide drills.

A variety of strategies can be employed to minimize deflection and/or improve hole precision. You can use precision ground rather than production inserts on the periphery of the tool to reduce tolerance stack up. Also, offset toolholders can be used. Inner inserts encounter higher cutting forces than do the outer ones, due to the lower cutting speeds, thus promoting higher deflective forces. To compensate, insert placement within the tool can be adjusted by the tool design engineer. Regardless of drill type, irregular surfaces can be pre-machined then pilot drilled. Strategies like these can improve performance, depending on the customer’s needs and priorities.

Because mold manufacturing employs tough materials, insert grades and geometries need to be evaluated for the best combination. The inner insert encounters higher cutting forces than the outer, so here you will typically want a very tough grade and a geometry not prone to chipping. In the outer pocket, running at higher speed, use a more wear-resistant carbide. This mixing and matching can optimize the process.

Choosing the right drill for your application can be a complex affair. That’s why a final tip is: Choose the right drill supplier, one with the applications engineering expertise needed to help optimize your holemaking operations.

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

Cutting Tool Strategies for Milling Ribs

A review of machining options for tapered rib processing, typically found in plastic injection and die cast molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More