Hot Runners for Technical Part Molding with Engineered Resins

See Us at amerimold Booth 617 and Register Today!

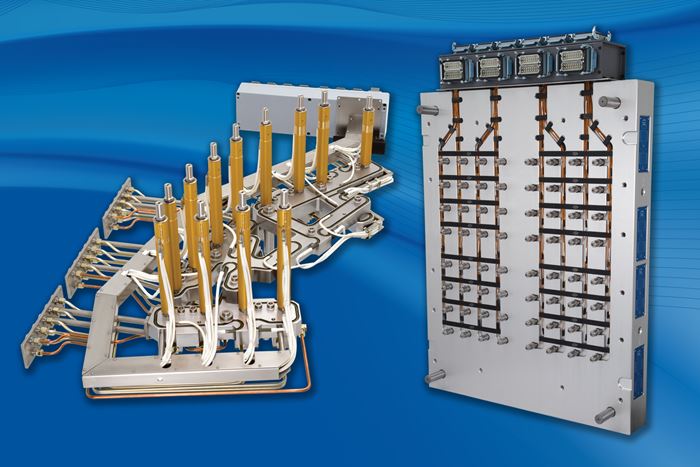

DIRECT-FLO™ (DF) Gold hot runners.

INCOE® (Troy, MI) offers its line of DIRECT-FLO™ (DF) Gold hot runners, designed for technical part molding with engineered resins. With shot weights up to 9000g, DF systems are ideal for automotive, appliances, electronics/technical, housewares and medical device parts. Standard system features offer the widest range of gating options with unitized leak-proof designs.

QUICK-FLO™ (QF) systems are used with commodity grade resins for caps and closures, medical disposables and pharmaceutical packaging applications which demand maximum output, repeatable part quality and superior cosmetics. With up to 375g shot weight capacity, complete hot half systems are included.

Both systems are available with OPTI-FLO® rheologically balanced manifolds featuring Beaumont Technologies Inc. patented MelfFlipper® technology which can provide improved cycle times and processing capability.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=600)

.jpg;maxWidth=300;quality=90)