Easier Graphite Dust Removal

Even shops using machines with venting and suction systems can end up dealing with heaps of fine black dust left from machining this abrasive material. Cleaning it up could be easier than you think.

Graphite is messy stuff, and moldmakers commonly buy machines with options designed specifically for the abrasive material. Yet, the dust can still be hard to control—hard enough that many shops have no doubt found their own clever ways of dealing with it.

One such method came to my attention while attending a machining technology supplier's recent open house event. While taking me through the ins and outs of a product, an applications engineer noted that he's seen shops save a significant amount of time on graphite cleanup with a common household item: petroleum jelly (Vaseline). Simply spread the oily substance throughout the machine’s work envelope (or anywhere else the stuff accumulates), and the graphite dust will stick to it rather than the machine surface. Once the cycle stops, wipe clean.

It goes without saying that, as the applications engineer emphasized, this is certainly NOT a substitute for vacuum systems, air purges, protective covers and other features of machines designed specifically for graphite machining. Beyond that, this strategy seemed a bit, well, gross to me, and possibly even impractical. But then I've never tried it, either!

Have you? If so, I'd love to hear about it. Likewise, send me an email if you've come up with any other unorthodox way of dealing with graphite dust.

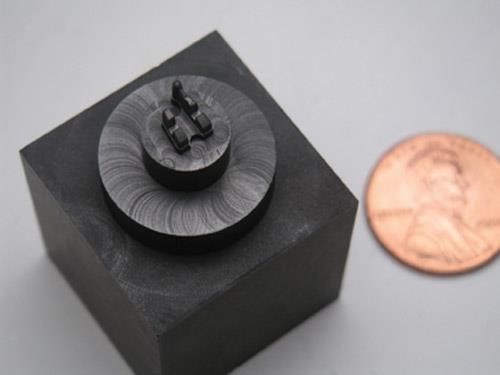

Of course, some shops prefer to avoid the mess of graphite entirely. Click here to learn why Chicago-area mold manufacturer B A Die Mold machines the vast majority of its electrodes from copper.

.jpg;maxWidth=300;quality=90)