Die/Mold Event Reveals Company on the Move

The latest in a monthly series of open houses at machine tool builder Hyundai Wia provided not only technology takeaways, but also insight into the company’s recent developments and future plans.

The difference may be difficult to spot, but look closely at the photo above, and you’ll see that the part on the bottom looks just a bit shinier. That’s due to more than just the lighting and the limitations of the camera on my iPhone 4S. Both parts were machined with a ballnose cutter like the one on the left, with the exact same parameters and the exact same program on a F510M three-axis VMC from Hyundai WIA. However, the one with the better surface finish was mounted at an angle to enable cutting not with the tip of the cutter, but with the flutes on the side, which spin at a relatively higher surface speed to impart a smoother finish.

This piece of wisdom was just one of many takeaways from the machine tool supplier's Christmas-themed “Unwrap the Solutions of Die and Mold” workshop. Hosted last week, this was the second installment in the monthly series of "Learn Today, Prosper Tomorrow" educational and networking events at the company’s Chicago-area U.S. headquarters facility. Notably, the tidbit about the ballnose cutter wasn’t conveyed in a powerpoint presentation or seminar, but rather, an informal conversation with Fred Puzon, product manager. And, it happened not during normal business hours, but at roughly 6 p.m. Attendees were also treated to beer, wine, soft drinks and catered food (the meatball sandwiches were particularly tasty). The idea here—and the idea behind future "Learn Today, Prosper Tomorrow" events—is to make it as painless as possible for busy manufacturers to network and educate themselves.

That said, those with the time to take an entire day were also treated to a slew of more formal presentations during normal business hours. Moreover, those presentations weren’t just from Hyundai WIA, but also suppliers including Mastercam, Bohler Uddeholm, OSG Tap & Die, Big Kaiser, Haimer, Siemens and Fanuc (all of which stuck around later for the more casual evening portion of the event). The company says this range of partners evidences its focus on not just machine tools, but the entire manufacturing process chain, from software to spindle to cutting tool assembly and workholding. In fact, the company says it will invite such partners to host future events of their own at its Itasca, Illinois facility. Cutting tool manufacturer Sandvik Coromant is already scheduled to host one such event in June.

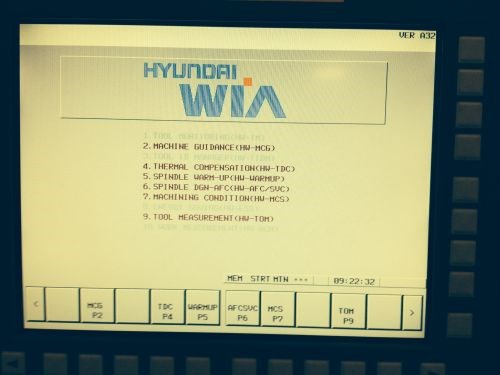

The F510M VMC’s FANUC CNC features a Hyundai WIA interface that provides access to various features that are said to be of interest to moldmakers in particular.

Moldmakers in particular might want to consider attending the open house in March. That’s when Hyundai WIA plans to unveil its new Hi-MOLD6500 VMC, a machine designed specifically for our corner of the industry. Many features will be identical to that of the F510M, including the custom, mold-focused control interface shown above. However, the newer machine is expected to offer improvements in areas including thermal displacement compensation, a major focus of the company’s recent R&D efforts. October will see the release of yet another new model benefitting from recent R&D, the five-axis XF600. In this case, however, improvements will relate to improved spindle durability and five-axis response, both of which are areas the company says it plans to strengthen in coming years.

Such R&D efforts are just one example of a company on the move. For one, much of the aforementioned research came out of Germany, where Hyundai WIA opened up a new facility this year facilitate improved collaboration with CNC manufacturer Siemens. Moreover, that location is just one of a number recent facilities the company has opened worldwide, including the U.S. headquarters facility where the event was hosted in Itasca. (In fact, I reported earlier this year on the company’s reasons for moving from New Jersey, where the company had been located since opening its first U.S. headquarters there in 2011.)

All in all, the South Korean parent company has invested more than $580 million in its machine tool division during the past year alone. Given this investment and the company’s stated goal of becoming a Top 5 machine tool builder worldwide by 2020, it will be interesting to see what the future holds.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)