Published

Critical Insights on Conformal Cooling

Industry colleague and proponent of conformal cooling has once again helped organize a technical conference to provide critical insights on reducing cycle times and reject rates with conformal cooling. This will take place on September 29 at the Toshiba Technical Center in Elk Grove Village, Illinois.

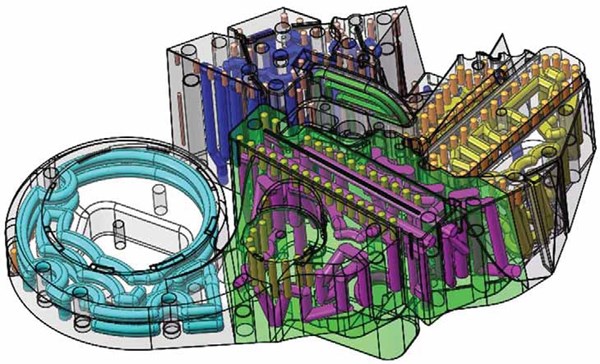

Photo courtesy of CONTURA MTC GmbH.

Industry colleague and proponent of conformal cooling Bob Beard has once again helped organize a technical conference to provide critical insights on reducing cycle times and reject rates with conformal cooling. This will take place on September 29 at the Toshiba Technical Center in Elk Grove Village, Illinois.

The 2015 Conformal Cooling Conference will focus on the practical application of conformal cooling coupled with rapid heat/cool technology and provide moldmakers, OEMs and brand owners with information to help improve their process and reduce costs. Additionally, the conference is ideal for technical, engineering and management professionals at automotive and medical companies.

A live demonstration of both conformal and conventional cooling technologies will be featured. As an added bonus, a rapid heat/rapid cool demonstration will be conducted on the same molds (provided by Linear Mold & Engineering). This will allow attendees to observe, in real time, the impact and benefit of these emerging technologies. Robert A. Beard & Associates, Inc. a provider of technical, engineering and management support for plastics and Plastic Technologies, Inc., a global leader in plastic-based package development are the conference sponsors.

Conformal cooling of injection molds is a game changer in the molding industry. Typical cycle reductions of 20 to 40 percent can be realized. Lower reject rates are accomplished because of uniform cooling and stronger parts are achieved through lower molded-in stress,” Beard says.

Event speakers include:

- Dr. David Schwam, Case Western Reserve University, Applications of Conformal Cooling and Additive Manufacturing in Die Casting

- Jason Warr, Linear Mold & Engineering, Conformal Cooling—Improving Manufacturing One Layer at a Time

- Kip Perykowski, Regloplas, Advantages of Pressurized Water Mold Heating for Dynamic Heating of Injection Molded Parts

- Reiner Westoff, Contura MTC GmbH, Using Aerospace Technology to Build Conformal Cooled Mold Inserts

- Jeff Higgins, Autodesk, Understanding the Benefits of Conformal Cooling

Fees are $495 for the 8 am to 5 pm, one-day session, which includes lunch and conference

related materials.

For more information click here and to register click here.

.jpg;maxWidth=300;quality=90)