"Common Sense Manufacturing" Concept Drives Efficiencies at Byrne Tool

A 100-percent commitment to Common Sense Manufacturing (CSM) has helped Byrne Tool + Design reduce waste on multiple levels and drive improvements and growth.

Common Sense Manufacturing (CSM) is what drives continuous improvement and lean manufacturing at Byrne Tool + Design in Rockford, Michigan. This shop is small but mighty, with buy-in to the CSM concept palpable among its 24 team members. “Best is the enemy of better” is the viewpoint at Byrne Tool where they favor creativity over capital, and 5S principles rule.

The company opened its doors for fellow members of the American Mold Builders Association to tour the day before attending this year’s annual conference.

Interestingly, or perhaps uniquely, Byrne Tool’s culture is one of near autonomy. Employees work as a team or independently, no one has set hours and there is no shop foreman. It is a self-directed workforce. When a job hits the shop floor, each person who will work on the mold is given a completion date that he or she must meet to keep the job on schedule and to avoid keeping co-workers waiting. It seems to work, because attendees learned that of the 19 employees who work out in the shop, 14 of them have been employed at Byrne Tool for at least 15 years.

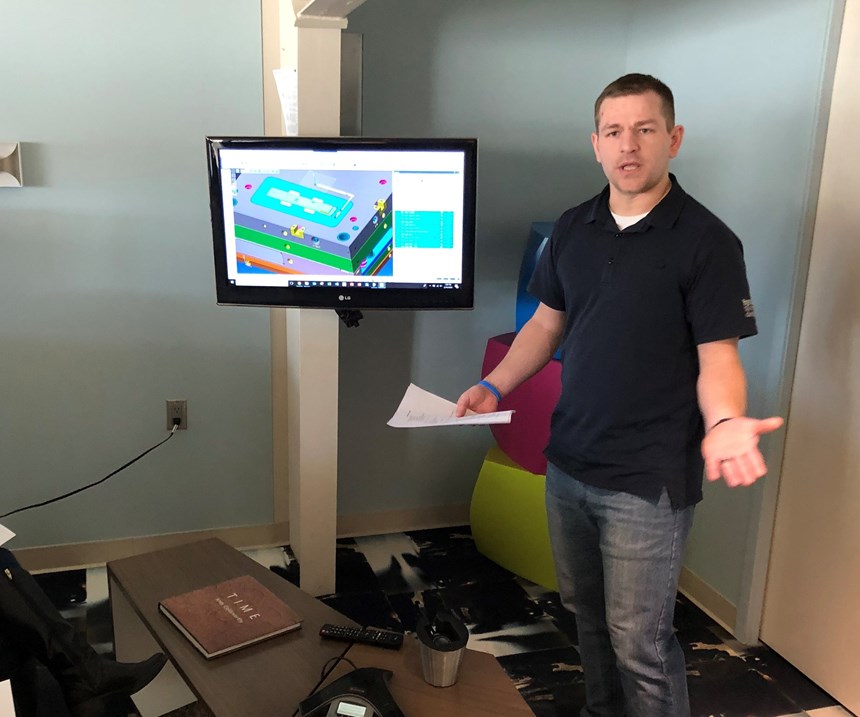

One Byrne employee explained that the company holds eight CSM events a year. Employees submit ideas for the focus of each two- to three-day event. “We use the blitz approach, which means when we pinpoint an issue, we get in there and work together to try to make it better, whatever it is. We are not aiming for perfection, because you aren’t going to achieve that in two or three days. We want improvement.” He said when he was new to the company, his first CSM event entailed shutting the entire plant down for a week and everyone, toolmakers included, worked to “5S” the shop, washing walls, floors and even the ceiling, cleaning machines, and getting every nook and cranny of the place organized. Everyone was paid a week’s salary to do this. “People complained, but after a while the benefits of holding these types of events began to show, especially in the way our customers began to see us,” he said. More recently, the company held a CNC department CSM event aimed at making sure all of the CNC programmers were following the same processes and were properly trained on the new software. Byrne Tool has four CNC machinists that run two primary machines and they do their own programming.

Byrne Tool entered into the additive manufacturing market four years ago when it purchased a Stratasys Fortus 250mc, which takes a filament of ABS, draws a perimeter around the part, fill it in, and then drop in a layer, repeating the process until the part is complete. Mark Mitchell, Design Center manager for Byrne, said the machine was used at first primarily to prototype parts for customers who wanted to be able to test them for form, fit and function.

Byrne then soon realized that they could start printing out fixtures for the parts. “After about four years of using this technology, we decided seven months ago to step it up. Our customers began to ask for finer detailed parts They wanted color, different materials, so we purchased the Stratasys J750,” Mitchell said. The J750 can print in over 350,000 colors, including matching (or very nearly matching) pantone colors. It also prints rigid or flexible materials, transparent materials, rubber and digital ABS, which is the main reason the machine was purchased. For one customer, he says, while getting started on a production mold design and build, they print a prototype ABS mold, which takes a day or less, maybe overnight.The customer takes the prototype, molds parts and sends them to UL for design approval without having to wait for the finished steel mold.

Common Sense Manufacturing on all levels gives Byrne Tool + Design a competitive edge over some shops twice their size—maybe larger. Quite impressive.

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)