Button Cutters Reinvented

Button cutters still offer a competitive edge in many manufacturing processes, despite claims they are being phased out.

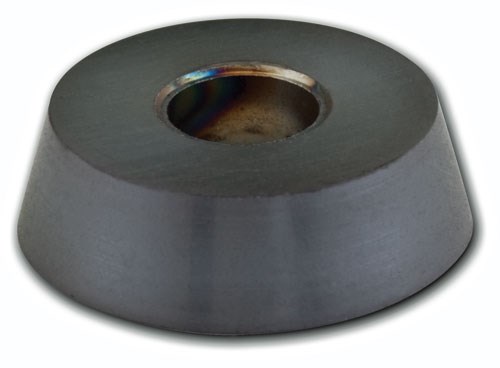

A button cutter is defined as a face mill that uses a round insert. The name comes from the appearance of its insert because the round insert resembles a button. This geometry and face mill style have been in use for decades and earned a reputation for safe, reliable machining. However in recent years, many manufacturers have been replacing their button cutters with high-feed geometry. This quick fix to increase productivity feels natural because it takes very little effort in process changing. Replace a three-inch button cutter with a three-inch high-feed face mill, change the spindle speed, change the feedrate, and overnight you have quadrupled your shop’s productivity.

Your tooling salesperson tells you that they just saved you $200,000 a year, and now you believe that you have taken your shop to the next level. Some of that may be true, but what happens when you are trying to use an older machine? What happens when you are machining something that is not in solid state or after heat treatment?

The point is that every tool has its application, and even with newer technology the button cutter cannot be replaced in every machining application. Many see the higher metal removal rates of high-feed geometry and think the button cutter has become obsolete. This article will illustrate that this assumption is not completely accurate and moldmakers should reconsider the benefits of the time-tested button cutter.

Button Cutter Benefits

A button cutter is a versatile machining solution that can be optimized on newer high-velocity machines as well as older, slow equipment. To be used on newer machining centers, the inserts are now being produced from consistent sub-micron grain-sized carbide substrates. They are manufactured perfectly repeatable using the latest in 5- and 6-axis grinding technology. These improvements in tolerance and properties make the button cutter more effective at higher spindle speeds and more usable on today’s higher end machining centers.

Button inserts are combined with the latest edge preparations. By using hones, K-land, T-land or combination preparations, they are suitable for light depths of cuts at high feedrates or heavier conventional machining operations. This allows a button insert to be applied to any machine and most materials.

The geometry updates are being combined with the latest in PVD coating technology. Using low-friction, nano coatings and special coatings for specific applications allows the inserts to effectively manage the heat of high-speed machining or exotic materials.

The improvements in geometry, carbide and coatings would be insignificant without reinventing the button holding systems. As tool steels have improved, so have the shanks and arbors used to hold the button insert. They are available in many different lengths and designs for the best possible reach and rigidity. They have become unbelievably accurate with high precision manufacturing, which virtually eliminates run out. New designs consist of multiple rake angles, variable flutes, offset flutes and combination designs suitable for any material.

Finally, round inserts allow the use of more edges than other geometries. Being able to rotate a round insert 360 degrees makes it the most economical insert available. Today’s button cutters still have a competitive edge.

Proper Application

The most important part of any machining application is to know your process and limitations. New school machinists will tell you machining is a science. Old school machinists will say machining is an art. So who is right? Actually both!

Taking a comprehensive look at your process/limitations and then correctly applying the science of machining to maximize your shop’s throughput is the art of machining. There is no one-size-fits-all approach to machining and no silver bullet to increase your shop’s productivity.

Analyzing your processes, machine capability, setup limitations, programming ability and other manufacturing factors to maximize your shop’s potential will determine your tooling needs. With the art of machining in mind, the button cutter can be a versatile tool in many 2D and 3D milling operations. They can be used for many types of applications—such as shoulder milling, slot milling and helical interpolation. This versatility, combined with a rigid shank design and strong cutting edge, makes the button cutter a stable manufacturing solution—a setup that is most effective in difficult operations and materials where other tool geometries often fail.

A shortfall of high-feed tooling is non-solid state machining or re-roughing. Many machinists still try to achieve these operations with high-feed tooling, but then cannot believe how many inserts they are going through. With rigidity, a strong cutting edge and stability these operations can often be achieved more effectively with a button cutter.

Other operations such as re-rough after heat treat, welded rework, extended reach re-roughing/semi-finishing, hardened Z-Level facing, interrupted cuts and fine Z-level finishing are applications where button cutters still have a competitive edge. However, the one-size-fits-all approach to productivity often results in premature wear of other geometry inserts and an inflated tooling budget.

This is where the newer technology in button cutters can correctly be applied. There are more extreme benefits of the button cutter in overly difficult machining operations, such as in the following example.

Example

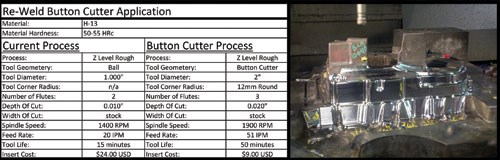

A button cutter process was adapted to a difficult-to-machine welded part (see Figure 1). Due to the inconsistent hardness and stock conditions generated by the weld, the machining process became fiscally challenging to produce. The current process consisted of a one-inch ball nose tool doing a Z-level machining process to remove access weld. However, the low metal removal rate, poor tool life, machine burden rate and cost of the insert, revealed the obvious need to review the process and limitations. After a review of all the factors involved, a one-inch button cutter process was put in place that doubled productivity and brought tooling cost down 88.8 percent.

Summary

Taking a comprehensive look at your process/limitations and then correctly applying the science of machining to maximize your shop’s throughput is the art of machining. With recent tooling advancements—such as high-feed geometry—the art of machining has become less important in the search for a quick fix to productivity. However, a button cutter is still a versatile machining solution that can be optimized on newer high-velocity machines as well as older, slow equipment. The improvements in carbide, grind technology, coatings and holding systems have made it relevant in many machining applications today. Although the role of the button cutter has changed in recent years, the science of machining will never phase out the art of a button cutter.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

The Myth of Cutting Tool Cost

Evaluating machining productivity by comparing tooling cost to tooling productivity.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)