Attention to Details

According to Beaumont Technologies--developer of melt-rotation technologies-- it’s oftentimes the little decisions we make that eat away at the profitability of a company, and many times we don’t give them a second thought. Read their take on how your choice of runner shape can shape your profits.

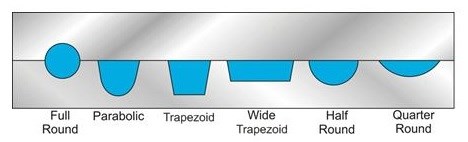

Whenever designing a cold (solidifying) runner system, a decision must be made as to the shape of the runner channels. The most common options for runner shapes are shown in the Figure above. In terms of the preferred shapes, start on the left side and work your way to the right. However, it is not recommended to go much further than the trapezoid shape. The other three runner shapes are inefficient, have no value and will waste a great deal of plastic and energy.

The full round runner shape is the most efficient, which simply means that it provides for the lowest pressure drop given the same volume of plastic. The main disadvantage of the full round runner is that the moldmaker has to machine the runner into both halves of the mold. Along with that, the two halves must closely align to avoid mismatch which could result in filling variations. Due to the additional machining and alignment concerns, designers and moldmakers often prefer to use either a parabolic or trapezoid shape.

There are also cases when a designer used a full round runner shape in the mold design, but the moldmaker took it upon himself to change it to a parabolic runner for whatever reason. The thought being that the mold will still fill, right? So what’s the big deal? Read more here.

To hear Beaumont Technologies speak live on how scientific runner design increases productivity, attend the amerimold expo on June 11 in Novi, Mich. when Alex Beaumont and Andrew Clouse of Nifco North America hit the show floor stage. Visit amerimoldexpo.com for details and Register Today!

Related Content

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)