Photo Credit: (top left) Swoosh Technologies & Solutions, (top right) The Polymers Center (bottom left) B A Die Mold Inc. and (bottom right) Meusburger.

This latest Amerimold technologies and services compilation wraps up the exhibit previews received by MoldMaking Technology.

For a recap of other exhibitors that will be making an appearance at the event, take a look at the Technology Showcase Part 1, Technology Showcase Part 2 and Technology Showcase Part 3. Or, visit the Amerimold 2021 website for a complete exhibitor list.

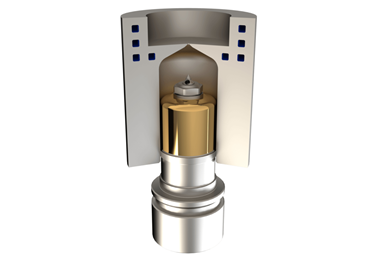

CUMSA USA introduces its new remote date stamp system to achieve a more reliable, precise and controlled traceability approach, not only to identify when the part is molded, but to also quickly recognize what parts are affected if any engineering change or recall situation may happen.

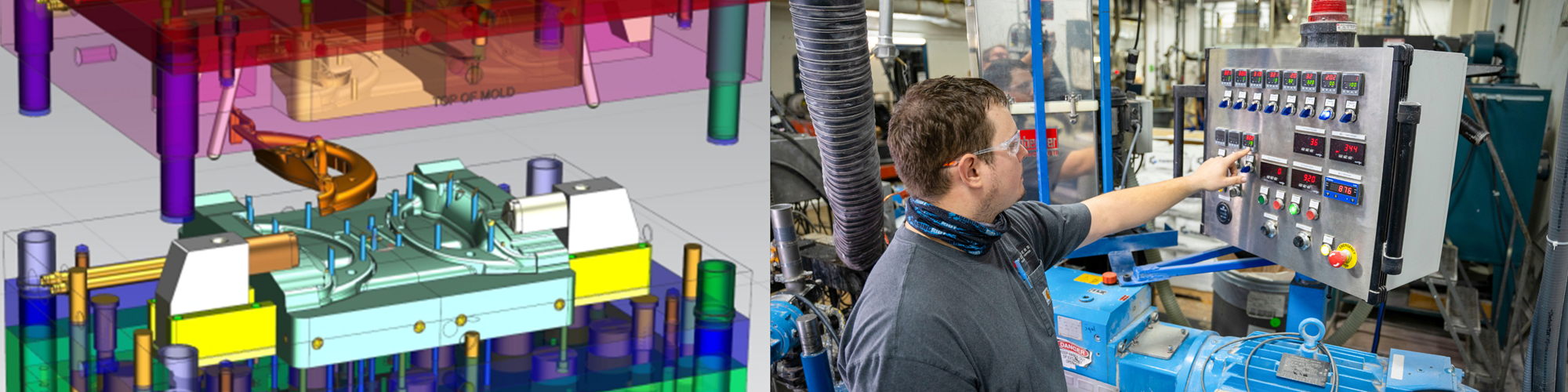

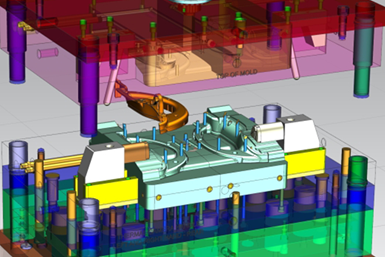

B A Die Mold Inc. is a designer and manufacturer of high-quality, precision injection, thermoset and compression tooling that is highly regarded for its Class A unscrewing molds for threaded parts. In particular, the company says its patented Programmable Electric Rotating Core (PERC) system is a frequently sought-after technology.

PERC is fully programmable, highly accurate and requires little to no maintenance.

Boy Machines Inc. underlines its servo-driven BOY 100 E injection molding machine with a 1,000 kN clamping force as an example of equipment that consumes less energy in the production process, thus reducing the ecological footprint and improving cost effectiveness.

In late 2020, the American Mold Builders Association (AMBA, Indianapolis, Indiana) identified a need to address workforce development in a way that would be impactful to its membership. As part of this strategic decision, the AMBA team moved forward with the creation of its 2021 Workforce Development Task Force—which is made up of AMBA mold manufacturers—to work towards its goal of completing one to two workforce development-oriented projects this year.

Blue Wave Ultrasonics Inc. manufactures heavy-duty ultrasonic cleaning systems and environmentally friendly detergents specifically designed to clean molds and tooling used in plastic molding and extrusion applications. These systems are said to create a powerful, microscopic scrubbing action which effectively removes outgassing residues, grease and rust from even the most intricate molding areas—including water lines—and eliminates the use of of hazardous solvents and surface damaging abrasives.

The Cold Jet LLC i3 MicroClean 2TM dry ice blaster is said to build upon and enhance the company’s time-tested and proven i3 MicroClean technology. In addition to a 25% performance improvement with a pulse-free blast stream, the dry ice blaster is said to retain a more versatile cleaning capability with a wider application range, as well as offer a more efficient operation with a 20% reduction in consumable consumption, resulting in lower operating costs. Further, the i3 MicroClean 2 blaster provides users with more power compared to previous models for the removal of tough contaminants.

Swoosh Technologies & Solutions, a Siemens Digital Industries Software Platinum Partner, presents Siemens NX Mold Wizard to Amerimold 2021 attendees. Created for the next generation of mold designers, it is built on a powerful product development system: Siemens NX. According to the company, the CAD software providers users the tools necessary to increase productivity, make changes faster, virtually test performance, produce drawings and create CNC data, all within the same system.

MoldTrax MTWEB, the newest version of Amerimold 2021 exhibitor MoldTrax’s documentation tracking system, is said to be the only mold maintenance program created specifically for efficient tracking of the performance, maintenance efficiency and repair costs of injection, rubber, blow and die cast, stamping, cutting and forming dies. The system also enables users to standardize their terms throughout the system for easier, more accurate data entry for use in reports for mold performance and maintenance efficiency calculations.

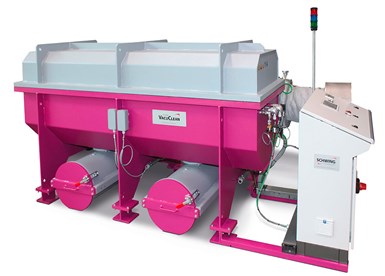

Schwing Technologies highlights its VacuClean pyrolysis system at Amerimold. VacuClean is a vacuum pyrolysis system for removing plastic residues from critical machine tooling, dies and filters. According to the company, VacuClean removes polymer from tooling within eight to 30 hours, depending on the system size, components to be cleaned and polymer type. It is designed to clean parts without impacting them thermally or mechanically. It features an integrated catalytic converter system to clean exhaust air and wastewater.

DME Company is showcasing its S-Core collapsible core, EZ latch locks and servo unscrewing devices at Amerimold 2021, which offer multiple configurations, flexibility and ease of use.

Designed for flexibility and longevity, DME’s S-Core collapsible core offers multiple segment configuration. EZ latch locks are a rod that can easily be fitted to thin plates and uses cams for locking instead of springs and Servomold electric unscrewing products aid in molding internal treads, indexing plates for multi-shot application and linear movement.

iD Additives Inc. now offers a two-step cooling line cleaning system for extruders, which will be demonstrated at Amerimold 2021 in September. The Eco-Pro and Cool EX system is reportedly used to restore cooling lines that are partially or fully clogged due to calcium, rust and scaling. According to the company, this is a common problem that is usually the result of poor-quality plant water.

Melt-IQ, offered by Amerimold 2021 exhibitor Md Plastics Inc., is a melt sensing and advanced math modeling system for injection molding machines that reportedly has the potential to make any machine “smarter.” This ability to “learn to work” imparted into the polymer turns each injection mold machine into a Decoupled III Phenom, a process that involves filling the mold to a position, incorporating a second stage of fill/packing to pack the mold to a set cavity pressure and then holding over time until gate seal is achieved.

Euroheaters USA’s modular hot runner temperature controllers enable users to maintain a constant, desired temperature. Heating channel temperature is primarily detected with the use of an intelligent chip which has three normal, manual and stand-by working modes.

The switching elements of the Meusburger E 1820 flat latch lock and E 1840 round latch lock now come with a DLC coating for even longer service life and, due to excellent dry-running properties, suitability for use in cleanrooms.

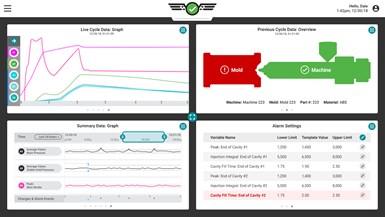

RJG’s CoPilot injection molding process control system is designed to be a user-friendly platform for producing high-quality parts. The CoPilot system enables users to observe what is happening to the part and identify when a process strays from the template, according to the company.

HTS iTherm, which can be integrated through any toolshop, with various options for manufacture, offers conformal cooling for injection molds, improving the ability to cool challenging inserts and cores, and often reducing cycle time or improving part quality. Material options include H13, 420SS and other standard tool steels.

The Polymers Center is a not-for-profit organization created to increase knowledge, provide technical support and assist companies in the plastics industry. Pilot, small-scale and toll compounding is available as well as product development. The company’s Materials Science Lab is said to be able to perform chemical and mechanical analysis of most polymers. Extrusion and injection molding training classes are available at the Center or at the customer’s facility.

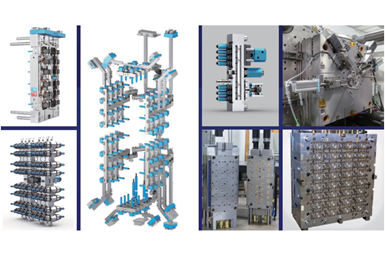

Westfall Technik has developed proprietary hot runner technology to produce parts ranging from 0.001 g to 400 lb. The easy-to-maintain hot runners are designed for longevity and reliability.

At Amerimold 2021, Westfall says it will showcase compact internal valve gate nozzles; O-ring free black box actuators; removable cartridge manifolds; moving slide manifolds; angled valve gate technology; easy-to-operate star gate nozzles and multi-tip valve gate nozzles; ISOKOR hot runner technology for micromolding; as well as other capabilities.

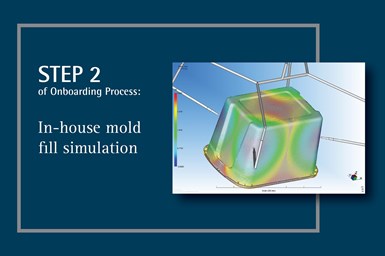

Cavalier Tool & Manufacturing, a global mold manufacturer and Amerimold 2021 exhibitor, emphasizes its exceptional customer service in plastic injection molding, which, simplified to a three-step onboarding process, is reportedly able to effectively reduce tool build time by up to 25%.

To improve its custom steel mold base and plate quality for its customer’s tooling projects, Amerimold 2021 exhibitor National Tool & Manufacturing Co. (NTM) says it has improved its surface grinding tolerance capabilities. According to NTM, its surface grinder was enhanced to provide a 0.0002 parallelism thanks to uniform machine quality, which is due to consistent preventive maintenance done according to factory specifications and recommendations.

The Commando XP Dry Ice Blasting Machine from Amerimold exhibitor Nu-Ice is designed for precise and delicate cleaning applications in plastics manufacturing, and is reportedly the ideal cleaning method for many types of plastic molds, including injection molds, rotational molds, blow molds, compression molds and more.

.jpg;maxWidth=300;quality=90)