3D Printing: Viewpoints from the MMT Editorial Advisory Board, Part 1

Each month, MMT has published editorial from its advisory board about 3D printing’s current and future prospects in moldmaking. Here are a few of them.

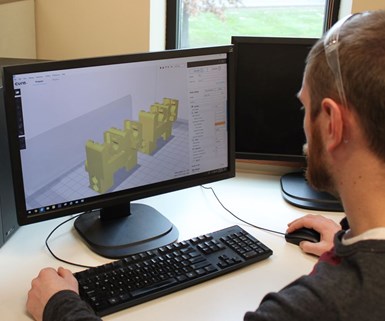

In each 2019 issue of MoldMaking Technology, members of our editorial advisory board have contributed their viewpoints about additive manufacturing and its role in moldmaking. What’s interesting is that each company has a different level of experience with the technology. Not everyone has invested in it for their shops, but all see the value of using it to educate, to produce better cooling solutions and to explore even more possible uses for it to advance mold manufacturing.

Below are summaries and links to four of our EAB members’ columns.

Putting 3D Printing to Work – Ryan Katen, Micro Mold Co. & Plastikos

Micro Mold and Plastikos

together have invested more than $400,000 in technologies and processes related to 3D printing and reverse engineering over the last three years.

A Systematic Approach to Laser Sintering – Richard Stueber, NyproMold

As an early adopter of laser sintering technology, NyproMold uses a very focused, two-step strategy for evaluating when it makes sense to use it.

3D Printing Offers a Link to Manufacturing Careers – Kylee Carbone, Westminster Tool

Evaluating 3D printing’s role in workforce development.

Digital Manufacturing Insights – Gabe Meldrum, Midwest Mold Services (formerly of International Mold Corp.)

When it comes to digital manufacturing, International Mold Corp. uses scanning, reverse engineering, and inspection, but has not ventured into 3D printing. A team attended an integrated digital manufacturing conference to learn more. Here is what they discovered.

To learn more about 3D printing in moldmaking, visit MMT’s Additive Manufacturing Zone.

Related Content

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

-

3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.