3D Printing and Coronavirus: U.S. Additive Manufacturers Share Their Experiences

Sister brand Additive Manufacturing shares the stories of how a few 3D printing companies have managed both the setbacks and opportunities that the COVID-19 outbreak has brought to light.

Editors’ note: The editors of Additive Manufacturing have heard from 3D printing businesses in the United States that have seen both positive and negative effects from the global COVID-19 pandemic. The stories range from increased orders as OEMs look to replace parts previously sourced from Asia, to new questions about social distancing and workplace policies. We are collecting these stories and will update this page with the newest information at the top as responses come in. If you have a story to share, email us.

For more information on business conditions, see Gardner Intelligence. To find 3D printing services, see our Supplier Directory. For guidance on approaching coronavirus as an employer, we recommend the CDC website.

(Responses may be edited for length/clarity.)

March 17, 2020

3D Printing Crowdsourcing to Help Overcome Supply Chain Shortages

In a public document titled “3D Printer Crowdsourcing for COVID-19,” more than 200 people from across the world have offered to help to produce vital hospital supplies amid the evolving COVID-19 outbreak. The idea came when a Northern Italian hospital needed a replacement valve for a reanimation device and the supplier had run out with no way to get more in a short time. An Italian company brought a 3D printer directly to the hospital and redesigned and then produced the missing piece.

I think this is a great idea to help hospitals care for an expected influx of coronavirus patients in times where there might be an inadequate supply of critical hospital equipment. This encouraging initiative of additive manufacturers shows their willingness to help, donate their manufacturing or design capacities in times of uncertainty — and the crucial role global networks can play in a global crisis. —Barbara Schulz, European Correspondent, Additive Manufacturing

3D Printing for Applications “That Do Not Typically Look to AM”

With the recent interruption to the supply chain due to the coronavirus, we’ve received requests to manufacture products that companies simply cannot get right now from China. We understand that a number of these customers have adopted “just in time” manufacturing processes and are carrying reduced inventory levels. While “just in time” manufacturing helps to reduce inventory and costs when manufacturing is running smoothly, it causes an immediate issue when products cannot be shipped or received.

Many of the requests we have received due to recent supply chain issues are for applications that do not typically look to additive manufacturing for design, production capacity or cost reasons. However, additive manufacturing solves their short-term product issue and allows them to keep or get product back on the shelves. —Ken Burns, VP Commercial, Forecast3D

March 16, 2020

Additive a Solution Where Standards, Material Supply Can Allow It

I heard from a senior manager with a company that supplies technology to additive manufacturing users. Off the record, he noted some of what he has been seeing with industrial 3D printing service providers in recent weeks. Many are seeing increases in business. He believes in some cases certifications or standards that would normally have ruled out additive manufacturing are being reevaluated for the sake of getting parts. One challenge with delivering on this new business: Additive manufacturing in some cases might have a supply chain extending to regions that have been affected, because raw material might come from China even though the part is printed in the States.

The business news for 3D printing in this time might actually amount to a net shift toward additive manufacturing for production as opposed to 3D printing’s more established uses. My source notes that while there are unexpected production opportunities arising from the virus situation, many larger companies are also making cuts to non-essential expenses during this time. Those cuts reduce the budget for prototyping. —Peter Zelinski, Editor-in-Chief, Additive Manufacturing

3D Printing Aids “Bridge Production of Necessities”

We have seen an increase in business from particular sectors that are suffering from supply shortage due to the slowdowns in Asia. We have also been working to aid in the bridge production of necessities such as face masks, which historically were manufactured with more traditional processes even though we have the capacity to produce them at 1,000 per day.

But, we have simultaneously seen a pausing of development and production of entirely new products. —Gabe Bentz, CEO, Slant3D

Service Bureaus “Ready and Willing to Help”

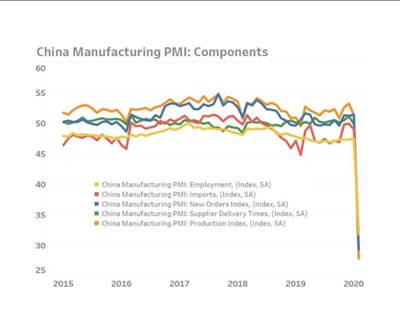

About two weeks ago I sat down with economist Michael Guckes to film a video conversation about China’s production manager’s index (PMI) and ways that U.S. companies might look to 3D printing as a solution for supply chain disruptions. Since that story posted, I’ve heard from a handful of 3D printing service bureaus with open capacity, ready and willing to help. (If this describes you, reach out to be listed in our supplier directory.)

While the situation is serious and bound to get worse before it gets better, I’m encouraged by the ingenuity and can-do attitudes of additive manufacturers. The silver lining could be that more eyes are opened to the possibilities of 3D printing as a result of the challenges U.S. manufacturing is currently facing. —Stephanie Hendrixson, Senior Editor, Additive Manufacturing

Related Content

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

In Coronavirus Uncertainty, 3D Printing Is a Potential Solution for U.S. Manufacturing

The impact of the COVID-19 virus has reached U.S. manufacturers by way of the supply chain. Here are several ways 3D printing could help, plus a video discussion of the data with economist Michael Guckes.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)