Enhanced Heidenhain StateMonitor Meets Machine Control Connectivity Needs

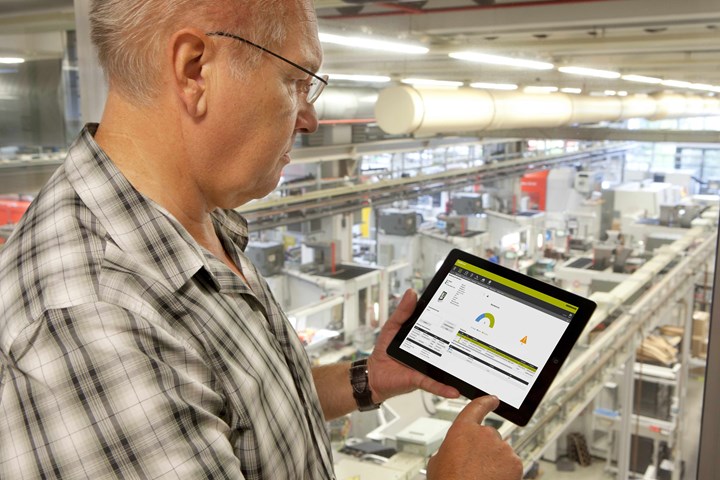

Heidenhain’s StateMonitor system, which will be presented at Amerimold 2021, avoids unnecessary downtime and bottlenecks, and enables machine data to be available on any device no matter the user’s location.

Photo Credit: Heidenhain Corporation

With its most recent 1.3.0 software upgrade, Heidenhain’s StateMonitor system now enables CNC manufacturers a modernized and more effective way to connect their control and PC systems. Including additional StateMonitor options, users involved in this Industry 4.0-connected machining initiative can view data and evaluate control processes remotely and in real time in a more simplified manner. Further, the system can be used to connect and monitor both Heidenhain and non-Heidenhain controls.

As a monitoring system, StateMonitor places an overview of the machine status at the user’s fingertips at all times, making it possible to react quickly in case of faults. The software helps to avoid unnecessary downtime and bottlenecks while at the same time improving machine utilization and availability. The machine data is available on any device that has a current web browser installed, no matter where its user is located—even on a tablet or smartphone.

In addition to an easy installation and start-up process, the software system adheres to strict user ownership of data; users are said to be able to dictate the amount and types of data collected for viewing from their various production facilities, as well as the specific applications evaluating it.

Some 1.3.0 StateMonitor enhancements and features include a MaintenanceManager option (option 6), for appropriate organization of maintenance and recording of their execution; signals (option 7), to enable the collection of machine-specific signals and their monitoring over any period of time; and database enhancement, which reportedly has a transition to a more powerful PostgreSQL database, and unique IDs to enable further reduction of access times to the collected data.

Exhibitor: Heidenhain Corp.

Booth 447 (P)

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

.jpg;maxWidth=300;quality=90)