Let’s face it, injection molding plastics can be difficult. It is a delicate balance of material selection, processing, and proper part/mold design. All these variables interact to give you a quality part within specification or work against you to cost you time and money to troubleshoot and fix. How do you confirm that you are running the best process to maximize profit?

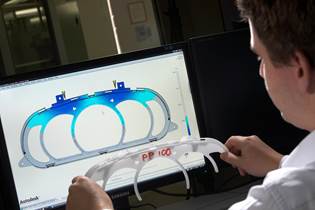

In this webinar Autodesk will explore how companies today use simulation workflows to identify potential issues, detect the significance of interaction effects between variables, and define custom quality criteria to produce a part with the least amount of risk. The information from simulation results can even be transferred to set up injection molding machine processes for quicker start up. Join Autodesk to find out more.

Primary Topics:

- Learn how simulation can be used to reduce manufacturing risk

- Using Design of Experiments to make more informed decisions

- Quicker machine startup with simulation input

Presenter:

Dr. Matthew Jaworski

Senior Subject Matter Expert, Autodesk Moldflow

Matt Jaworski is a Senior Subject Matter Expert for Autodesk’s Moldflow Simulation Team. He has over 25 years’ experience in the injection molding CAE simulation field working for such companies as Hewlett Packard, Rubbermaid, and Moldflow/Autodesk. He has dual BS degrees in Mechanical and Plastics Engineering Technology from Penn State, and MS, PhD degrees in Plastics Engineering from UMass Lowell. He is a member of the Society of Plastics Engineers and the American Society for Engineering Education. Matt is also active in education and has taught at the University of Massachusetts Lowell and Penn State Erie as an adjunct professor.

.jpg;maxWidth=300;quality=90)