COVID-19 Gives Mold Component Supplier Its Most Consequential Order Ever

The pandemic has presented challenges to every link in the mold manufacturing supply chain and those companies in a position to help have put their teams and processes to the test, including mold component suppliers.

can-do team moment

"This is a situation where human lives are at stake. Normally, we are making components for automotive tooling and the like, but never anything where there are human lives at stake," Phil Allor, CEO and Owner of Selflube says. On top of that, the parts were all custom, and the need for them was immediate.

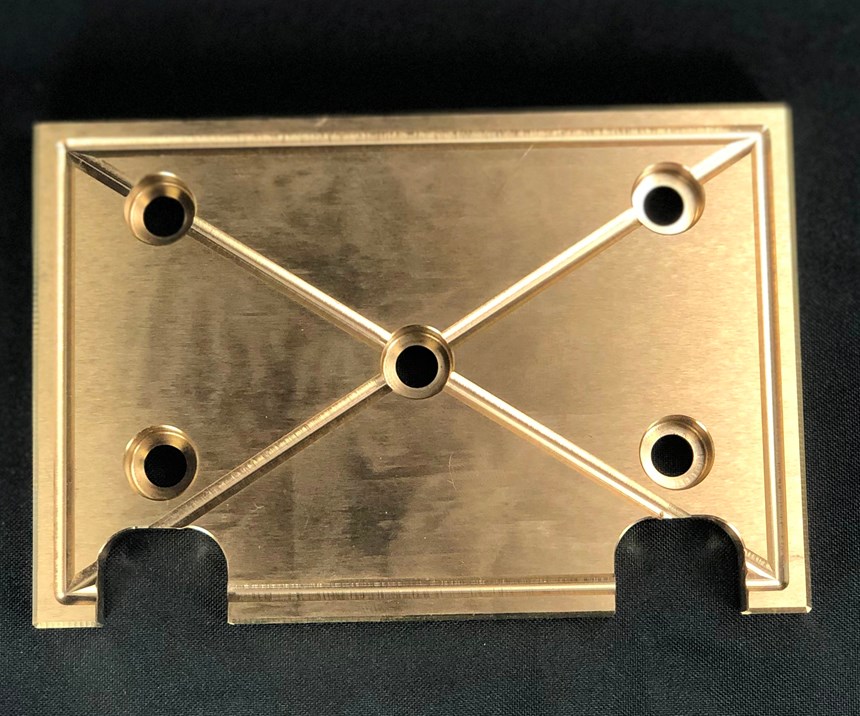

Hi-Tech Mold & Engineering approached Selflube to be part of Project V by manufacturing mostly bronze gibs and wear strips (Selflube's specialty) to control movement within a tool used to make critical components for a emergency room ventilators.

To fully understand the extraordinary nature of this situation, Allor told me that the typical turnaround time to produce similar custom parts is two weeks. The six-person Selflube team did the job in 3 days. The team accomplished this by prioritizing this rush job and put all other orders on hold. It became the team's highest priority because lives are at stake.

"We make a lot of custom parts and have proprietary software that helps us create the CNC code without too many keystrokes. We don't have to do a 3D model and go through all that trouble, and this part, fortunately, fit within the parameters of our system and was able to generate the code pretty quickly," Allor says.

The job demonstrated to Allor that there are a few steps in the process with which they are a little cautious because the company has a reputation for shipping on time without fail (short of a machine breakdown, etc.). "Our reputation for quality and speed makes us a little cautious when it comes to quoting lead times," Allor says. The outcome of this project showed the team that they can be a little less cautious in the future and still perform for the customer.

"It was one of those can-do situations. At the start, we all thought it couldn't be done because we've never done anything like this before. We amazed ourselves, and we're a little more confident now about taking short lead time jobs and making them happen for customers," Allor says.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)