Four Ways to Build a More Profitable Moldmaking Business

Sponsored ContentExpanding your moldmaking shop’s capabilities and efficiency will lead to a more profitable business. Here’s an overview of the technology—hardware and software—that will get you there.

Share

Mold makers operate in an intensely competitive environment. The amount of work available on any given day is finite, and if it’s not going to your shop, it’s going to a competitor’s.

One way to gain a competitive advantage is to maintain high efficiency. When you have the fundamentals in place, your shop generates high-quality NC programs with speed and confidence, setting the stage for CNC machines that run well and produce outstanding finished tools.

For many mold shops, efficiency is already very strong. So how do you improve your competitive position if you’re already doing everything right?

There is no simple answer. But if your shop is consistently performing at a high level, there is still ground to be gained at the margins. The following tips run the gamut from design to programming, from to setup to machining. Leading manufacturing software provider, Autodesk, offers a quick overview of some options your shop can easily put into practice.

1. Decrease Cycle Time with More Advanced Equipment

If you think an old machine is making you more money because it’s already paid for, think again. Today’s improved machine tools, tooling, workholding, control and CAD/CAM technology have made substantial gains over the last ten years, allowing shops to reduce the time it takes to machine cavities, cores, inserts and other components. And it’s not just about machining faster. Better machining technology also generates smoother, more accurate surfaces, which in turn reduces the need for subsequent EDM and benching operations, all of which can contribute to shorter lead times.

Better workholding and control technology can also reduce setup. Adding a rotating table to a three-axis machine, for example, allows you to cut more sides of a tool without the need to stop the machine, remove the fixture, reset it and square it up. Incorporating on-machine verification (OMV), also known as in-cycle measurement, onto your CNC machines can streamline setup and processing. During setup, OMV can be used to ensure the NC programs are correctly aligned with the stock being machined. OMV typically utilizes a spindle-mounted probe to pick up holes, edges and other features that can be used to set up machining datums. This can be done far quicker than using manual processes. Then, at predetermined times during machining, you can probe the part to ensure key areas are within tolerance.

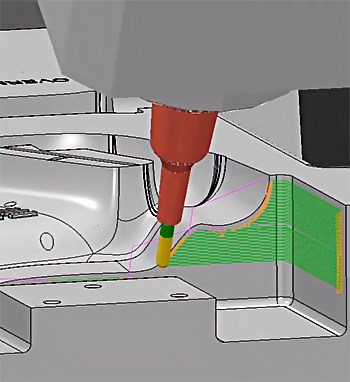

Five-axis machining takes it to another level. Whether full-five axis, or just 3+2 (continuous 3-axis machining with 2-axis positioning), this technology lets you get at more features of a cavity with a shorter tool. Keeping the length-to-diameter ratio as low as possible allows you to avoid running more slowly to avoid the vibration and tool “chatter” that can compromise part quality when tools are too long. Simply, the shorter the tool, the faster the machine can run and the better the surface finish quality.

Cutting tools are also getting more productive. Multi-flute cutters (6-8 flutes per tool), for example, allow much higher feed rates with no sacrifice in quality. Combined with five-axis machines, new barrel-shaped cutters allow you to significantly increase stepover distance yet still generate smoother surfaces.

2. Improve Equipment Utilization

Admittedly, better equipment is more expensive, at least initially, so you must consider how to get the greatest return on that investment. One way is to machine faster. Maximizing spindle utilization is the other. With faster setup and the ability to machine unattended with faster cycle times, shops can double the output of a machine, or more.

Collision detection and avoidance software that runs offline and on machine controls gives CNC machine operators the confidence to run programs unattended.

Setup reduction can be accomplished in several ways, all of which reduce downtime to keep CNC machines running as much as possible. Removable pallets with hydraulic clamps allow operators to run one job while prepping another, then swap out pallets and continue immediately instead of taking the time to clean up and re-fixture the second job only after the first is finished. These pallets can also be configured with up to a dozen individual mold inserts or components that can be machined simultaneously, as opposed to running one or two at a time in vices.

OMV helps here as well. During job setup, OMV can drastically reduce the time necessary to square up the block compared to a dial indicator. It also allows machinists to identify parts that can still be salvaged. If a part is beyond salvation, OMV can prevent any further time being wasted on a part that should be cast into the scrap bucket. OMV enables these decisions, and more, to be made in real-time—all without removing the part from your machine.

CNC machines can also be configured to send an alert to a designated operator or employee if they experience an issue while running unattended. Knowing immediately when a machine is stalled can save hours from the schedule that would otherwise be lost.

3. Pursue More Demanding Work

Having more capable equipment unlocks the door to doing more complicated jobs where the margins are higher, and the competition is smaller.

As product designers—and the CAD software they use—become more capable, tool designs have become more complex than ever. Techniques such as generative design, topology optimization and lightweighting allow parts to become increasingly organic in shape. These developments, alongside tighter delivery timescales, rising material costs and the ever-present threat of overseas competition, can put immense pressure on mold and die shops.

Instead of solid structural beams, the generatively designed seat frame has a bridge with hundreds of smaller lattice cells and several thousand small struts that vary in thickness to bear local loading conditions. The frame was designed according to European aerospace specifications for impact.

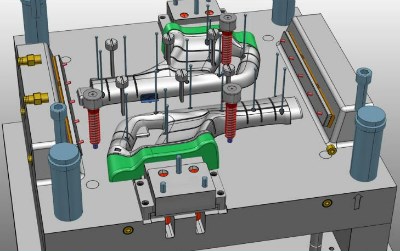

Less experienced shops will be incentivized to start producing more complex parts. In addition, organic designs naturally complicate the design of the molds. These typically require more complex cooling circuits and packaging to fit around the mold core or cavity.

Directly related to the demand for more complex parts comes a rise in disruptive technologies such as additive manufacturing (AM), or 3D printing. These new techniques allow you to create parts and tools that would be impossible to produce with conventional machining.

While AM is not going to replace conventional tool and die manufacturing any time soon, it does create unique opportunities for job shops to boost efficiency. If you make molds for plastic parts, AM can be used to 3D print conformal cooling structures that radically reduce cycle time. It may not be practical to print an entire mold with AM, but it may be appropriate to use for printing replaceable inserts. AM may be more cost-effective when creating tools that are deep with many pockets, such as automotive fascia, or bumpers.

4. Embrace Automation

One huge upside of CNC machines becoming more powerful is that they are better equipped to take advantage of automation, whether automating time-consuming programming tasks, setup processes, or running unattended. Some of these capabilities depend on the CNC machine itself, while others depend on the choice of CAM software. Whether it’s the hardware or the software, automation can drastically reduce labor and cut the total time it takes to build a tool.

Many steps of CNC programming can be automated, even when parts are very complex. One of the most important steps is organizing data logically, often by layers or colors, and consistently from job to job.

Organizing part design data logically and consistently saves time in part design and CNC programming.

With stamping dies, this involves creating separate layers (or colors) within the digital model for the part, fixture, trim steel, drilled holes, tapped holes and so on. This allows CAM software to apply the same process to similar parts, such as machining the part shape very tight but the surrounding shut-out faces less accurately, or adding EDM components to the edge of the trim steel.

These time savings really add up with stamping die projects that involve 30, 40, or 50 individual die components for shape, trimming, or punching. A similar approach can be used with plastic molds too, with different layers (or colors) used for ribs and electrodes, or each slider on its own layer so it can be pulled out and cut.

Alternatively, for similar shapes, feature-based recognition may speed up programming times by finding similar features and applying programming logic to them. Using templates for common jobs can dramatically reduce the amount of user input required to program jobs, allowing families of parts to be programmed with minimal human input.

PowerMill CAM software provides strategies for 3- and 5-axis subtractive and additive manufacturing. See what’s new with PowerMill.

Additional time savings can be made by converting your shop’s best practices (your “special sauce”) into a set of machining templates that can be shared across your CNC programmers. Not only does this save time, it allows lesser skilled workers to become productive in less time.

Finally, be sure to use digital stock models. CAM software needs to account for the presence of the remaining stock at all times. This is typically done with a virtual or digital model of the stock that enables you to develop roughing strategies that only cut away stock where there is stock left to be cut. In this way, a digital stock model allows you to use the largest possible tools up front and conserve the use of smaller tools. Finding these opportunities manually can take hours. Using a digital stock model to automate the process not only saves a great deal of programming time, it saves mill time later by eliminating any potential duplication of effort, or re-cutting areas that have already been cut.

If you feel as though you’re not prepared for this uptick in complexity, or find yourself struggling to keep up, it may be time to reassess your current equipment, processes and best practices.

Autodesk offers manufacturing software solutions for industrial equipment design, allowing manufacturers to produce complex products with informed factory layout tools and CAM software that results in efficient, high-quality toolpaths. Popular CAD/CAM solutions for mold making include PowerMill CAM software for 3- and 5-axis machining, PowerShape CAD software for molds and dies, PowerInspect 3D measurement software, MoldFlow simulation software for injection molding, and NetFabb for additive manufacturing.

For more information on how CAD/CAM software can improve mold making operations, visit Autodesk.com/MAKE.