Euromold Evolves, but Maintains Focus

Additive technology was a big draw at this year’s Euromold show, but traditional players have plenty to showcase as well.

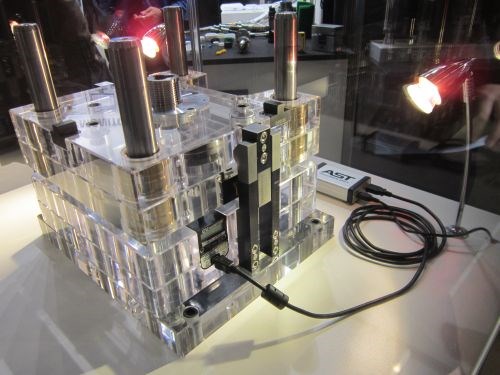

Progressive Components showcased this demonstration of its CVe monitoring system. View the picture gallery for more information on this and other offerings that caught my eye at Euromold.

By far the most travelled aisles of the Euromold show last week in Frankfurt, Germany were occupied by technology that, so far, occupies a peripheral role in the manufacturing of production tooling. Yet the mere fact that laser sintering, fused deposition modeling and other such technologies have found a home—and an audience—at the world's largest mold and die show could be seen as evidence that manufacturers in this sector who dismiss additive technology do so at their own peril. After all, one reason MMT attends Euromold year after year is that the technologies showcased at this event often forecast what North American manufacturers will be doing in the future, and all indications are that shops here are ready to invest.

Of course, the show also remains indispensable for more traditional players in the die and mold industry. This picture gallery showcases just a few examples of the technology they had on display. Stay tuned later this week for more on the additive side.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

.jpg;maxWidth=300;quality=90)