Photo Credit: (top left) API, (top right) Hasco America, (bottom left) Hexagon Manufacturing Intelligence and (bottom right) Regal Components Inc.

Throughout January and February MoldMaking Technology has published a diverse cluster of new and proven products launched by companies fulfilling needs for cutting tools, non-contact inspection equipment, mold components, hot runners, design software, machining and even molding machines. In case you missed it, we’ve compiled them below.

Note that this is only a small fraction of the products MMT’s editor posts. For those that appear online and in print, visit our “Magazine” found on the homepage.

For the full product post, click on each linked title, or find it under the “New Tech” section of the website.

Mold Components

The Hasco Loc Check A5900 component enables GSM tracking of injection molding tools at any time and location where the GSM network is available. This is especially useful, the company notes, when tools are used at different locations, or when they’re loaned to different injection molders.

Photo Credit: Regal Components.

Regal Components Inc. has introduced a line of high-performance beryllium-free copper-based alloy core pins for high-volume, high-heat plastics molding applications. The Regal BFP type high-conductivity core pins are made from a C-18000 beryllium-free copper-based alloy providing 95-98 Rockwell B (20-25 Rockwell C) hardness.

Hasco America is introducing a new line of latch locking units targeting injection molds with multiple parting planes to precisely control movement of the parting planes during the opening of the tool. Offering flexible mounting and combination options, Hasco says the new latch locking units offer double-sided latch function and assembly options, including the ability to be mounted outside the tool.

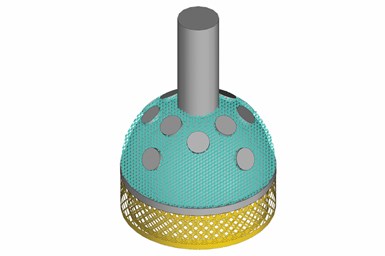

Additive Manufacturing

ESPRIT CAM software introduced by Hexagon’s Manufacturing Intelligence division now offers users the digital tools needed to prepare 3D-printed components for manufacturing using powder bed fusion (PBF) technologies. Because hybrid manufacturing entails performing both additive and subtractive processes, Hexagon notes, integrating build preparation tools within CAM software streamlines workflows per part and offers efficiency improvements when scaling up additive manufacturing (AM) volumes.

Software

Autodesk Inc. has made available the Production Design Extension and Simulation Extension, which have been added to Fusion 360, the company’s integrated 3D CAD, CAM, CAE and PCB software for product design and manufacturing. Initially highlighted during Autodesk University (AU) in 2021, these extensions improve the platform’s performance, user experience and efficiency.

Machining

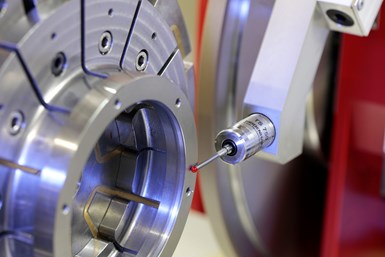

Photo Credit: Heidenhain Corp.

Heidenhain’s contamination-resistant, absolute modular magnetic angle encoder, the ECM 2400, provides machine tool users functional safety (FS) for machine feedback. ECM 2400 supplements the Heidenhain’s portfolio of absolute angle encoders and is designed for machine tool applications that require a sturdy encoder with medium accuracy.

Photo Credit: Jergens Inc.

Jergens Inc. highlights its new 130-mm double-acting hydraulic vise with high holding forces, quick clamping and repeatability for improved speed and part tolerance. The vise comes standard with multiple mounting patterns, different jaw options and easy access to plumbing and maintenance ports.

Heidenhain’s TS 750 high-precision touch probe is now available for in- process workpiece measurement in grinding machines and lathes. The highly durable probe offers the ability to state the reproducibility of its jobs at increased probing speeds with low probing force, the latter of which Heidenhain says is an important benefit when working with soft or delicate workpieces.

Molding

Photo Credit: Absolute Haitian.

Absolute Haitian, the exclusive sales and service partner in the U.S. and Canada for China’s Ningbo Haitian Machinery Co. Ltd., says the third-generation Zeres and Venus machine lines feature a 10% decrease in dry-cycle times, increased tie bar spacing, reduced overall layout, improved process control and 4.0 connectivity.

Trexel has introduced NC-Series Nitrogen Boosters to supply the nitrogen supercritical fluid (SCF) at the heart of its microcellular foaming technology to multiple Satellite Dosing Units, enabling what it says is a low-cost option to outfit multiple injection molding machines in the same plant with MuCell.

Hot Runners

The range of Vario Shot hot runner nozzles from Hasco, which are used primarily with particularly demanding plastics, has been extended. Moreover, Hasco says it has shifted the connecting cables of the nozzle outside the hot half in the nozzle retainer plate; a cable outlet to the middle of the nozzle is now available in addition to the heating outlet near the nozzle head.

Photo Credit: Oerlikon HRSflow.

Oerlikon HRSflow presents an additional development of its HRScool hydraulic cylinder system for hot runner injection molding, HRScool Evo, which, as a result of sophisticated temperature management, does not require active liquid cooling of the actuation unit. Further reduction in the heat flow between the hot runner and actuator now enables HRScool Evo to be used at higher mold temperatures than its predecessor system, HRScool.

Inspection/Measurement

Hexagon’s Manufacturing Intelligence division announced the HP-L-10.10, a non-contact laser sensor for CMMs that offer manufacturers the ability to perform dimensional measurements at comparable accuracy to tactile probing and rapidly inspect almost any surface.

Photo Credit: Nikon Metrology.

Nikon Metrology’s industrial microfocus X-ray computed tomography (CT) inspection solutions are now enhanced with a novel Offset.CT reconstruction algorithm, adjustable FID and rotating target technology for more progressive scan speed and image resolution.

Automated Precision Inc. (API), inventor of the Laser Tracker, has launched a thoroughly re-engineered version of its iScan3D hand-held 3D scanner. iScan3D is the third-generation version of API’s metrology-grade scanner. It is designed for portable shop floor dimensional inspection and scanning markets to provide both accurate measurements and point-cloud generation from a single-handed ergonomic sensor.

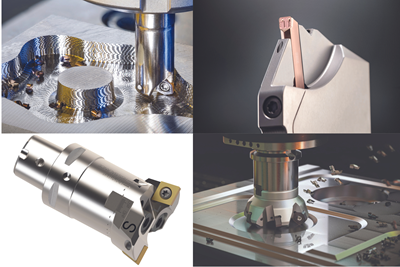

Cutting Tools

Parlec, a member of Techniks Tool Group, has released a line of U.S.-made BMT65 toolholders made from ductile iron. According to Parlec, ductile iron has 6.6 times more vibration damping properties than alloy steels, enhancing cutting tool performance and extending tool life.