MMT Blog

March 2024 Technology Roundup Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to hot runner products, that have been shared this month.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreImpacts of Auto’s Switch to Sustainability

Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreDesign for Maintenance: Five Tips to Extend Tool Life and Simplify Maintenance

Want to extend tool life? You need a design for maintenance approach. Learn five essential tips for getting started with design for maintenance in this webinar presented by Canon Virginia, Inc.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MorePassion, Potential & Unlimited Career Possibilities

The Advanced Manufacturing Design Technology Team at Central Community College in Hastings, Nebraska, talks about their facility expansion and their 100 years of instructor experience that helps to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.

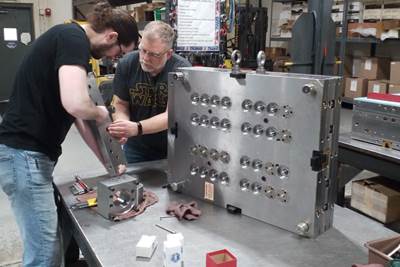

WatchHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreFather/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and a team’s collective mold manufacturing experience earn customer loyalty for 56 years and set the business up for future success.

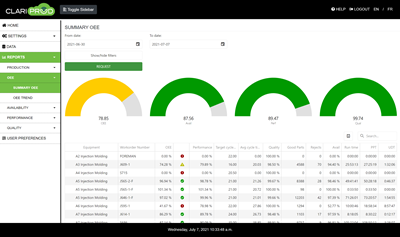

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreHow to Implement a Remote Validation Process

A review of the setup and use of a remote mold validation kit.

Read MoreOn a Mission to Develop Mold Designers

Editorial Advisory Board member Nicholas Vitelli—a lecturer in the Plastics Engineering Technology Program at Penn State Behrend— discusses the need for better-trained plastics engineers and mold designers to help businesses solve problems.

WatchTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read More

.png;maxWidth=300;quality=90)