10. How to Use and Protect Remote Machine Monitoring Data

Manufacturing relies heavily on data analytics to enhance performance. Remote machine monitoring, which gathers and analyzes machine data in real-time, is crucial for identifying and addressing issues promptly. This article provides a comprehensive list of six key benefits of remote machine monitoring for moldmakers.

8. Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

The Beckman Coulter Diagnostics’ Global Plastics team needed a packaging solution seamlessly integrated with their DxI 9000 IA analyzer, minimizing material content and capitalizing on recycling opportunities. Beckman Coulter approached Plastic Ingenuity to partner on designing a custom thermoformed package to hold and protect 520 pipette tips in four rigid polystyrene trays. This article covers the trials and tribulations of that process.

6. What's So Cool About Manufacturing? Students Use a Camera to Find Out

DVIRC, a local manufacturing extension partnership (MEP) organization, is a private, not-for-profit entity that supports the growth of small- and medium-sized U.S. manufacturers, distributors and R&D labs. One way they do this is by supporting and growing the industry’s talent pipeline through the What’s So Cool About Manufacturing (WSCM) Program for the southeastern Pennsylvania region, sponsored by the H. Howard Colehower Foundation. The overarching goal of the WSCM program is to transform students’ perceptions of manufacturing and manufacturing careers through a video contest. Read more.

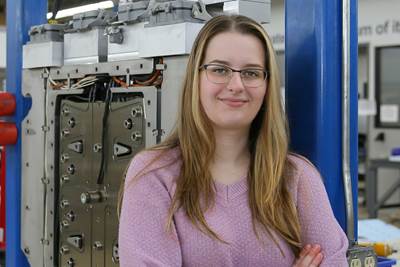

4. Electroform and Hononegah High School Partner for Hands-On Moldmaking Education

In another article addressing workforce development, Rockford, Illinois-based mold builder Electroform has partnered with Hononegah Education Manufacturing Connection (EMC) to promote manufacturing. More specifically, moldmaking and molding, by providing real-world, hands-on experience in manufacturing and engineering. Read more.

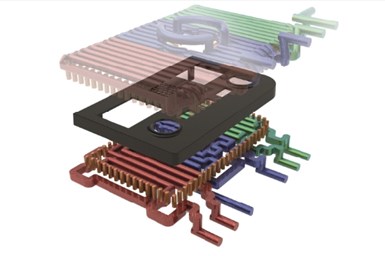

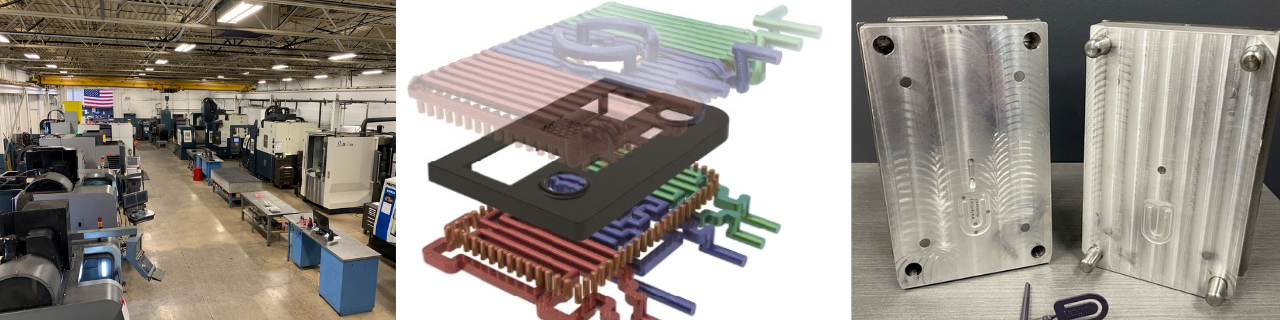

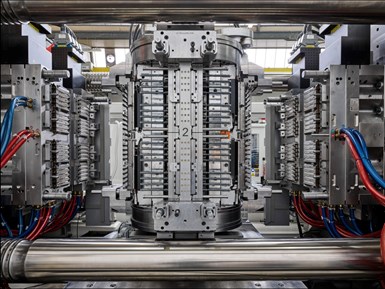

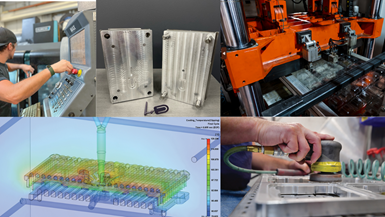

2. How to Use Simulation to Achieve a High-Gloss Surface Finish

Source: SimpaTec

Using process simulation early in a project, such as optimizing temperature control systems and comparing manufacturing methods, can streamline product development and manufacturing processes while achieving a high-quality, glossy surface finish for a part. Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts. Read more.

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read More2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

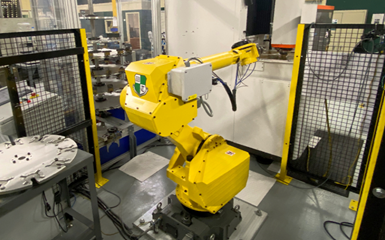

Intelligent Equipment Solutions Alleviate Moldmaking Pain Points

Whether it’s purchase quoting, mold cleaning and tracking or intuitive process control, the following new or improved technologies could potentially keep your shop on the cutting edge.

Read MoreMoldMaking Technology's Most-Viewed Content of 2023

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

Read MoreMentorship Matters: A Fresh Perspective from a Young Female Newcomer to a Mature Male-Dominated Industry

Jane Huot, a 23-year-old mold designer and project manager, celebrated her one-year anniversary with Accede Mold & Tool by going on her first business trip to a conference geared for women in plastics and shadowing sales on customer visits.

Read More

_300x250 3.png;maxWidth=300;quality=90)