Emerging Technologies at NPE2024: Exhibit Previews

NPE2024 will be held May 6-10 in Orlando, Florida. Check out the exhibitor preview compilation below to learn more about the exhibitors and the technologies related to moldmaking that will be featured.

Share

Sources (Clockwise): Technojet Machinery, Agathon Machine Tools, Athena Controls and High Tech Laser and Polishing Inc.

NPE2024 — The Plastics Show, is just around the corner, scheduled for May 6-10 at the Orange County Convention Center (OCCC) in Orlando, Florida.

Occurring every three years, this event attracts leaders and creative thinkers across a wide board of industries. The event is hosting more than 2,000 exhibiting companies, idea-generating zones for networking and a plethora of keynote speakers.

A number of NPE exhibitors have sent Moldmaking Technology exhibit previews for a sneak peek into the technologies, solutions and processes they will be showcasing at their booths. What follows is a summary of the companies and previews we have received so far.

Click on each company’s name for the full exhibit preview.

- Adler Industrial Solutions: The company exhibits its selection of Pinnacle Molds and Rapid Mold solutions.

- Agathon Machine Tools: The company showcases it’s latest tool guide system, the Guide System Plus, which provides main tool guiding, but also the fine centering between mold halves.

- Alliance Specialties and Laser Sales: The Advantage from Alliance Specialties and Laser Sales is a laser engraving system with a compact footprint, featuring a MOPA fiber laser.

- Athena Controls: The company highlights five controllers that provide features or enhancements for increasingly precise hot runner temperature regulation.

- Boy Machines Inc. (BMI): BMI’S U.S. subsidiary marks its 50th anniversary in Orlando with six machines and U.S. intros for the Procan ALPHA 6 control, and hybrid ejectors and injection units.

- Burger & Brown Engineering: Low-flow applications can benefit from the company’s Smartflow solution, which provides high visibility into the flow channels of molds to ensure bench verification.

- Cavalier Tool & Manufacturing: Cavalier Tool is showcasing its multiphase shift into more automated processes for lifters, inserts and slides manufacturing.

- Cold Jet: Dry ice cleaning solutions that elevate sustainable and productive operations for mold cleaning are made possible through Cold Jet’s smart blaster machines.

- Cool Clean Technologies: The company offers dry ice blasting and CO2 snow cleaning methods for more sustainable, no-touch surface preparation and plastics deburring.

- Crafts Technology: Proprietary CraftAlloy pins highlighted by Crafts Technology offer molders high thermal conductivity and high hardness for lightweighting and reduced wall thickness of parts.

- CUMSA USA: The Model F cylinder is being launched by CUMSA to control pre-opening movements in the mold. Maintenance and installation are further simplified.

- Custom Etch Inc.: The company brings its knowledge in laser texturizing, engraving, marking and labeling to mold builders and molders via new technology investments.

- DME Company: Electric Servomold systems by DME answer the demands made on high-performance injection molds, enabling precise, more environmentally friendly process reliability.

- Ellwood Specialty Metals: The company exhibits its EllCast 2 aluminium plate. Its strength at high temperatures, combined with high thermal fatigue resistance and hardness, makes EllCast 2 ideal for critical applications.

- Engel: The company offers attendees seven different exhibits featuring its selection of injection molding machines that address various parts of industry.

- Ermanno Balzi Srl: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

- Ewikon: The company is introducing the pro Edge VG range which sets new benchmarks in terms of ease of maintenance, gate quality and flexible use.

- Fast Heat by Spark Industries: The MOD24, by Fast Heat by Spark Industries, gives mold builders and toolrooms unlimited plug and play while combining the benefits of independent and integrated hot runner controls.

- Frigel North America: The company is presenting improvements to many of its processing cooling equipment, as well as debuting new options for North American customers, such as the Microgel series, 3DP4 4.0, 4DK series and more.

- Gesswein: The Sisma SWA 450 F laser welder targets large or small mold repair, backed by intuitive software functions, a high-energy laser and an adjustable laser arm and head.

- Globeius: The company and its suppliers showcase solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

- iD Additives: The company is featuring live, in-booth mold cleaning demonstrations using its Eco-Pro 360, in addition to an exhibit of its other mold cleaning solutions.

- Incoe Corp.: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

- International Mold Steel (IMS): IMS showcases its DCMX steel as an alternative to S7, providing mold builders uniform hardness for even machinability and clean welds and other benefits.

- Hasco America Inc.: The company introduces Mould Track for the precise tracking of injection mold inventory for improved production planning.

- High Tech Laser & Polishing Inc.: The company highlights its services, including mold polishing, laser engraving, laser texturing, laser welding and more.

- Husy Technologies: The company debuts the Ultrashot injection molding system, designed to increase overall part design freedom with high scale and quality.

- Keyence Corp. of America: The VS Vision System by Keyence incorporates fast setup time and built-in AI to ensure for quick inspection and real-time data visualization.

- KraussMaffei: Alongside partners, the company provides a comprehensive look at its offerings — from injection molding machines to automation and additive manufacturing — as well as partnerships, to advance its focus on sustainability.

- Kruse Analysis Inc.: The company presents its workforce management framework for optimized organization and management of human resources.

- Mantle: The company highlights its additive manufacturing technology designed for precision tooling, including the availability of 420 Stainless Steel.

- Mastip Inc.: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

- Mitutoyo America Corp.: The company addresses increasingly complex mold design testing with SJ-210/SJ-410 surface roughness testers and the MiSTAR CMM, geared toward inline automation.

- MiVue: The company, a division of the ACS Group, is showcasing expanded capabilities for its plant monitoring software for plastics processors.

- Mold-Masters: New hot runner systems, temperature and motion controllers, an auxiliary injection unit, a gate seal and sustainable processing solutions will be displayed at Mold-Master’s booth.

- Mold-Tech Inc.: Dedicated to complete quality and support, the company continues to add to its hard milling equipment department with the Makino D200Z, enhancing mold lead times, accuracy and efficiency.

- Mouldpro ApS: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

- M.R. Mold & Engineering: The company showcases its proprietary line of products for liquid silicone rubber (LSR) and plastic injection molds alongside four industry partners.

- MSI Mold Builders: The company is featuring a number of products developed across several industries, all successfully manufactured via its steel or aluminum molds.

- Oerlikon HRSflow: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

- Omega Tool Inc.: The company continues to invest in high-speed milling, toolholders and cutting tools to enhance its specialization in turnkey projects, maintenance, mold sampling and inspection/quality control.

- PCS Company: The company introduces several new products, including the MCS system, hot runner alarm systems, sprue bushings, a micro-TIG welder and its full Smartflow product line.

- Plastix LLC: The company provides a firsthand look at a variety of solutions for hot runner mold protection, manifolds, mold cooling and fitting installations to transform injection molding processes.

- Progressive Components: The company showcases ProFile v4, a cloud-based system for mold monitoring and asset management.

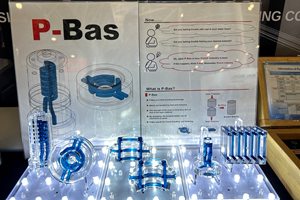

- Punch Industry USA Inc.: The company exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

- RJG Inc.: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

- Sodick-Plustech : The company, alongside Matrix Tool and RJG are highlighting injection molding machines, custom tool and molding capabilities and an AI-powered interface, respectively.

- StackTeck Systems Ltd.: Global moldmaker StackTeck Systems demonstrates a new approach to producing an ultra-thin, clear container made with 100% PET resin, mold and automation system innovations and more.

- Standex Engraving Mold-Tech: The company specializes in managing every step of the project process, from texture design and engraving to preparing the tool for production.

- Stäubli Corp.: The company highlights its adaptable QMC123 technology, which is capable of calculating the clamping force for each mold beforehand, in addition to ensuring worker safety.

- Technoject Machinery Corp.: The Star Line Crown Mini, offered through Technoject Machinery, provides edge gate technology in a small package.

- The Plastek Group: An emphasis on reverse engineering, 3D printing and conformal cooling design capabilities brings high-quality molding and tooling concepts and processes to The Plastek Group customers.

- The University of Massachusetts Lowell (UMass Lowell): UMass Lowell extends an invitation to its Alumni and Friends Reception to university alumni and industry professionals, highlights successful programs giving hands-on manufacturing experience.

- Top Grade Molds: Co-injection mold technology by Top Grade Molds promotes environmental sustainability, without compromising quality or performance.

- Uddeholm USA: The company showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

- Westminster Tool: Thee company is showcasing how it continues to expand its toolmaking knowledge through latest case studies, and mold qualification and injection molding training expansion.

- Wintriss Controls Group: The company is demonstrating the advanced features behind its ShopFloorConnect software and ShopFloorTracker hardware, key to capturing, tracking and managing data collection.

- Witosa GmbH: The company, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

- Wittmann USA: The company showcases five injection molding machine work cells, integrated with robots, auxiliaries and 4.0 technologies to highlight their efficiency and sustainability.

- Yudo USA: The company features Yu Drive II Eco, a compact solution that doesn’t require a separate controller, operating only by combining injection machine signals.

Related Content

Corrosion-Resistant Mold Steel Designed For Polishability

NPE2024: Uddeholm showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreLSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRead Next

NPE Educational Program Explores New Technologies, Business Strategies and Sustainability

One important feature of NPE2012 that will set it apart from all other plastics expositions is the rich educational program.

Read MoreNPE 2024 Set to Showcase Solutions for 6 Key Moldmaking Trends

The moldmaking and plastics industries have undergone some changes in the past six years, all of which emphasize the importance of innovation and adaptability for competitiveness.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)