2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

Since opening 25 years ago, JMMS (Easley, SC) has changed with the times. The second-generation, family-owned metalworking company has moved from a singular focus on consumer molds into the aerospace, appliances, automotive, electronics, lawn and garden, medical technologies, power generation, power tools and returnable packaging markets. The toolmaker’s ability to evolve and adapt to a changing business environment has earned it the 2011 Leadtime Lead Award: Small Shop Honorable Mention.

David Bowers II, JMMS CEO, describes his company’s business model as “next generation tooling.” He says the model combines the traditional strengths of full-service metalworking and conservative business management with a company-wide emphasis on continuous improvement in processes and cutting-edge technologies.

These strengths have fostered the development of a diversified toolmaking portfolio. “Unlike other companies that live or die with specialization, we never wanted to depend on one type of tooling,” Bowers says. “Our success comes from offering total mold lifecycle management across a wide range of tooling for plastics and metal forming. We design, engineer, test, manufacture and maintain extrusion blow, thermoplastic injection, thermoset injection/compression, thermoset compression and transfer, low-pressure injection structural foam, die casting and trim dies. Like any effectively diversified portfolio, growth in one asset class helps offset losses in another, for continuing net gains.”

Weathering The Economic Storm

According to Rich Martin, JMMS Business Development Manager, the company re-evaluated and retooled both its strategy and operations over the last two years. “We had the financial strength to make substantial capital investments in best in class technologies,” he notes. “We invested in IT. And we revised our branding and implemented an integrated marketing program. The economy was slowing down, but we thought the timing was right to address the business fundamentals.

“We made personnel changes too, staffing up at the project management and shop foreman level, and adding designers in our Asian operations,” Martin continues. “And we’ve created a strategic and tactical business plan, designed to target new market opportunities and address the specific requirements of key prospects. This retool has driven a 40 percent increase in sales from 2009 to 2010 and we’re positioned for even greater growth in 2011.”

JMMS offers its customers highly competitive leadtimes, averaging 10 to 12 weeks for domestic molds and seven to nine weeks for global molds. The company has a mature Asian toolmaking strategy in place, with design and toolmaking resources in Dongguan City, China. The company’s Asian toolmaking supports what Bowers calls the company’s “follow the sun” design and development. “We pack more productivity into 24 hours, because our Asian colleagues are starting work on designs when we’re finishing for the day,” he says. JMMS project managers, working under the auspices of the company’s ISO 9001:2008 Certified Management System, oversee each phase of the mold’s lifecycle, from design and engineering through installation, production and maintenance.

“Our process involves constant course checks and ongoing dialogue with our customers,” Bowers notes. “We review the tryout data together, consult on-site during design maturation and optimization, and move with deliberate speed from prototyping to production. JMMS believes in a best practices approach to ensuring molded part manufacturability, so we continue to re-engineer our processes to improve quality and compress the development cycle.”

Investments in Automation and Training

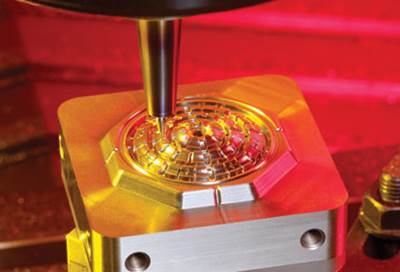

JMMS added an OKK HM1250S horizontal machining center in 2009, giving it the capacity to build larger molds for one of its largest customers, and the company continues to invest in lights-out manufacturing. “Our automated work cells use the latest robotic technology for increased capacity and consistency,” Martin said. “We have a five-axis robotic cell to manufacture all EDM electrodes and then the EDM process itself. All of our CNC equipment has automatic tool changing capability and we’re planning to add robotic cells in our CNC machining department to permit pallet interchanges with the four- and five-axis equipment.”

JMMS stays close to its customers to remain current with new technologies. “We talk to our customers and prospects all the time, asking questions to make sure we understand what they want from their mold and die maker,” Bowers says. “Our capital expenditures have to support the customer’s strategic investment in quality. The OKK machining center is a case in point. It gives us the capability to produce tooling for large parts, including components for instrument panels, hoods, doors and fenders. We added the technology to support one customer relationship, but it’s an integral part of our business development arsenal too.”

The company has also begun to implement lean manufacturing principles. JMMS associates study with the South Carolina Manufacturing Extension Program, learning how to identify and eliminate waste in processes and inventory; and JMM S management has started mapping value streams to support continuous improvement in quality and shorter leadtimes. “Our customers have seen the benefits of Lean in their own operations,” Martin notes. “They want to know that their vendors have made a similar commitment to organizational excellence.”

Engineering Controlled Growth

JMMS plans to grow, to meet additional demand for its next generation approach to toolmaking, while maintaining a flat organization and promoting from within. “We’ve worked hard to build our culture,” Bowers states. “When you have employees who share your core values, you don’t need to add layers of management to enforce compliance. People do the right thing without constant supervision, so everyone can focus on creating value in the design, engineering and manufacturing of tools and dies.

“We want to establish JMMS as the Southeast’s leading single-source provider of design, engineering, manufacturing and maintenance for molds and dies,” Bowers concludes. “We plan to continue investing in our capabilities and our customer relationships, while presenting the ‘next-generation tooling’ model to prospects who share our values and commitment to quality.”

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)