ESSENTIAL READING

VIEW ALLHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

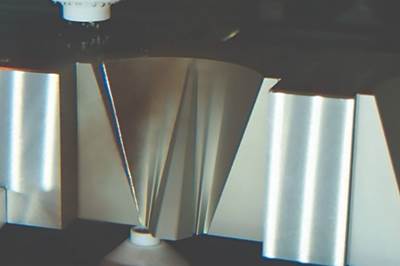

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreHow to Use Diffusion Bonding to Optimize a Mold’s Thermal Performance

Joining dissimilar metals has tremendous potential for conformal cooling, but to successfully use diffusion bonding, a mold builder must understand the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond.

Read MoreLatest Mold Materials News And Updates

VIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

WatchStainless Steel Series Benefits Blow Mold and Vac Form Applications

Molder’s World Inc.’s stainless steel mold material, Vortex is designed to ensure a smooth part with the measured release of gases during the molding process, providing better detail on the part and faster part production.

Read MoreMold Material Enables Additive Manufacturing Capabilities for Tooling

Uddeholm USA features its mold material Corrax as the first additive manufacturing (AM) powder made for tooling. Corrax is a stainless steel made for AM with corrosion resistance and polishability.

Read MoreEDM-3 Graphite Enables Moldmakers to Meet Strict Precision Requirements

IMTS 2024: Entegris Poco Materials highlights its EDM-3 graphite, known for exceptional strength, wear resistance and fine surface finish characteristics and thus an ideal solution for moldmakers’ most demanding applications.

Read MoreLarge Aluminum Mold Plate Sizes Enable Machinability for Moldmakers

Vista Metals highlights one of the largest aluminum mold plate sizes available on the market, its Duramold-5 Aluminum Mold Plate produced in super slab sizes for high strength to weight ratios, machinability and a virtually porosity-free structure to meet moldmakers’ critical surface finish requirements.

Read MoreOvercoming Barriers to Automation Integration in Precision Moldmaking

It’s easy to imagine the advantages automation offers the moldmaking process, but it's challenging to change one’s mindset, develop a plan and invest.

Read MoreFeatured Posts

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreTechnology Review and Sourcing Guide 2024: Mold Materials

Building a high-quality mold requires the proper selection of appropriate mold materials. Tool steel, aluminum, copper and alloys are a just a few examples you can fin in this exclusive, online-only content that includes a supplier list for mold materials.

Read MoreFive Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

WatchHow to Machine Aluminum Molds to Enhance Efficiency and Quality

Ways to optimize the machining process to fully leverage the benefits of an aluminum mold.

Read MoreFAQ: Mold Materials

What are the benefits of alloying tool steel?

Steels with a chromium content of at least 12% are generally considered corrosion-resistant. Martensitic tool steels have a high chromium content of 16% and a carbon content between 0.33%-0.38% that provides quenching and tempering during which only tempering carbides appear in the microstructure, leaving behind enough chromium to ensure corrosion resistance.

The resistance to corrosion is based on the formation of surface layers, protecting the metal from further reaction with oxygen. The most effective element is chromium. In combination with oxygen, it forms an oxide layer (chemical configuration: Cr2O3) on the surface, which shows a dense and amorphous structure as the chromium content increases. The formation of this Cr2O3 surface layer of approximately one nanometer promotes passivation, a process that protects the material against surface corrosion and ensures the functionality of the mold.

Alloying with molybdenum improves resistance to pitting corrosion, as it contributes to stabilizing the passivating Cr2O3 layer. In addition, molybdenum builds into the structure of the layer and strengthens it by preventing the removal of oxygen from the respective layer. Using stainless steels alloyed with molybdenum can also avoid corrosive attacks during mold cleaning, preventing hazardous products from entering the production process.

(Source: The Benefits of Alloying Tool Steel)

How can moldmakers optimize the quality of recycled plastic for molds?

The successful use of recycled materials in injection molding depends on how the original parts are recycled and re-pelletized. The two most important factors for producing a quality pellet of recycled plastic with consistent material properties are:

- Re-melting. Proper re-melting of the recycled material occurs under very low shear rates in the extruder and at the lower end of the melt temperature. The objective is to gently re-melt the original material, which ensures maintenance of the material properties.

- Melt filtration. The proper filtration process will remove any contaminants in the melt like cellulose, metal or wood pieces. State of the art melt filtration is fully automated and does not require manual operation steps. The melt is filtered continuously at low pressure and can remove particles as small as 70 microns in diameter.

Today’s recycling systems can help produce consistent quality plastic pellets that moldmakers can use in a wide variety of injection-molded parts.

(Source: Putting Recycled Plastics to Work)

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)