Five Axis

MMT's Most-Viewed Case Studies in 2024

Did you miss any of MoldMaking Technology’s most-viewed case studies from 2024? Now’s your chance to dive into these trending topics.

Fiona Lawler

Associate Editor, MoldMaking Technology

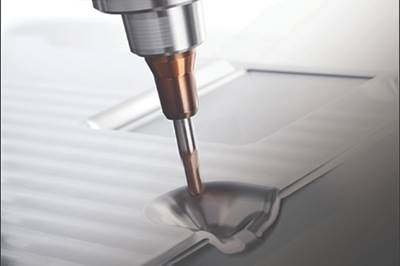

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreFive-Axis Portal Milling Machine Enables Precise Processing of Long Components

IMTS 2024: With the custom machine line FZG, Zimmermann offers a five-axis portal milling machine with a low rail gantry in their program, which is designed for processing long components.

Read MoreFive-Axis Machining Cell Enables Unmanned Operation

IMTS 2024: Kitamura Machinery showcases the Supercell-300G five-axis, horizontal machining cell designed for compact machining and a pallet pool system, along with other CNC automation systems.

Read MoreFive-Axis Range Displays Complex, Compact Machining

IMTS 2024: Grob Systems Inc. showcases a range of five-axis machines with horizontal spindles designed for high precision, improved accuracy and flexibility.

Read MoreVMC Tackles More Seamless Simultaneous Five-Axis Machining

IMTS 2024: DN Solutions features the DVF 5000 Second Generation, featuring faster speeds and a larger work envelope for complex workpiece machining.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Christina Fuges

Editorial Director, MoldMaking Technology

Double-Column Machining Centers Improve Accuracy, Speed of Mold Machining

IMTS 2024: Takumi highlights its UA400 five-axis and VC1200 three-axis machining centers for mold machining, designed to minimize thermal growth and accelerate feed rates.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreCustom Machining Solutions Feature Automation, Digitalization

IMTS 2024: Mazak features advanced machining solutions designed to boost productivity in automation, multitasking capabilities and machine tool technology.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read More2024 Software Suite Update Optimizes Tool Paths, Machining Capabilities

Open Mind brings updates to hyperMILL, with enhanced core toolpath strategies as well as new functionality for increased NC programming efficiency.

Read MoreCMM Programming Software Features Five-Axis Infinite Positioning

Infinite positioning, a highlight of Verisurf Software’s CMM Programming & Inspection Suite, enables continuous motion, optimizes part access and provides high-accuracy part measurements.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

How to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

Read MoreMold Builder Invests in Five-Axis Milling to Open the Envelope

NPE2024: Mold-Tech Inc., dedicated to complete quality and support, continues to add to its hard milling equipment department with the Makino D200Z, enhancing mold lead times, accuracy and efficiency.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreVMC Provides Versatile Machining of Complex Parts

The Mazak North America VC-Ez 20X vertical machining center features a 25-horsepower 12,000-rpm CAT-40 spindle with a 30-tool-magazine automatic toolchanger.

Read MoreHybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

Mazak’s VC-500A/5X vertical machining center delivers hybrid multitasking and hot wire deposition to meet machining and additive needs.

Read MoreSpace-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

Read MoreMaximizing Machine Tool Potential With CAM Software

Identifying specific areas where CAM software can utilize machine capabilities to benefit the user and maximize milling machine potential.

Five-Axis VMCs Attend to Versatile Machining Task Needs

Mold shops can choose from YCM Technology’s CF/CX or RF/RX Series of machines whether for simple or more demanding machining operations.

Read MoreHigh-Efficiency Milling Excels in Specialized Parts Production

GF Machining Solutions Mikron Mill E 500 U offers moldmakers a sturdy, reliable five-axis machine with integrated automation opportunities.

Read MoreMachining Center Provides Robust, Dynamic Milling Qualities

Roughing and finishing deep mold and die cavities is optimized using Chiron’s FZ 16 S five-axis machining center equipped with an HSK-A 100 interface, enabling reduced chatter, dynamic machining and the ability to tackle difficult materials.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreFive-Axis Machine Expands Advantages for Moldmaking

Optimized tool path and cutting angle control, access to hard-to-reach surfaces and overall efficiency and precision make Expand Machinery’s Gen Mill 5X-24 machining center optimal for the mold and die industry.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)