VIDEO: Addressing Data Needs with Mold Component Solutions

The need for data to track information and the history of the mold-building process is ever-increasing, and mold component solutions can help.

Hasco CEO Christoph Ehrlich and Hasco America GM Rene Eisenring discuss digitalization as a driver of technology that puts more data into customers' hands. The need for data to track information and the history of the mold building process is ever-increasing, and mold component solutions can help, including:

- Software technology that offers precise tracking of injection mold inventory for improved production planning.

- Mold components with GSM tracking, magnetically attaches to free surfaces of an injection mold and has a battery life up to 3,000 transmission cycles, enabling fast localization of injection molds.

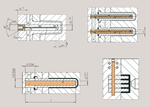

- Radiofrequency identification (RFID)-chipped mold tags to enable reliable and direct access to all injection mold unit information.

- An online portal that provides global designers, moldmakers and injection molders the ability to search, configure and easily order from more than 100,000 standard components.

All of this data plays a role in sustainability, according to Hasco. For example, digitalization gives mold builders and molders mold locations and order histories to easily locate a replacement part, instead of purchasing a whole new assembly or even the mold because you lost the information or the mold itself. This takes sustainability to the next level. Allowing mold builders and molders to existing items, repair and get back up and running in no time at all.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

.jpg;maxWidth=300;quality=90)