Share

Diamond polishing compound options are available for hard or soft metals requiring different levels of precision. Source (All Images) | Boride Engineered Abrasives

Diamond compounds, whether oil- or water-soluble, offer an ideal solution for polishing a diverse range of hard and soft materials in moldmaking. These compounds, sometimes referred to as “diamond pastes” in professional circles, play a crucial role in achieving precise and superior finishes across various applications.

The meticulous combination of natural and/or synthetic diamond particles with a water- or oil-soluble base creates a highly effective polishing medium. This blend ensures optimal cutting capabilities and superior finishing results. To maintain consistent quality and facilitate easy application, diamond compounds are conveniently packaged in syringes.

Professionals in mold and die polishing frequently turn to diamond compounds for final or mirror-finishing applications. These compounds prove versatile and suitable for a broad spectrum of materials that require quick stock removal, pre-polish lapping, pre-polishing and final polishing. Tailored to meet the demands of different metals, diamond compounds are available in various precision levels.

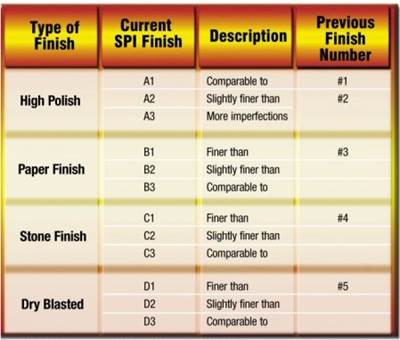

Diamond compounds are graded to cater to specific polishing needs. Lower grades, such as one or smaller, excel in creating a final, fine finish. In contrast, higher grades, like 25 or above, are designed for stock removal or earlier polishing stages. The choice between these grades depends on the precision requirements of the task at hand.

The base of the diamond compound, whether oil or water, also plays a crucial role in its performance. Oil-based compounds offer improved adherence to the surface and enable increased heat during polishing without causing damage. Water-based compounds, on the other hand, facilitate easier cleaning post-polishing and are preferred for molds set to be coated. In most cases, polishers opt for oil-based diamond compounds due to their advantageous properties.

Professionals specializing in mold and die polishing often rely on diamond compounds for final or mirror-finishing tasks.

The color of diamond compounds corresponds to their grades, aiding users in quick identification. Darker colors like black, brown and purple are indicative of compounds suited for stock removal, while lighter colors like white, light gray and yellow are associated with smaller grades for final polishing. Multiple grades and colors are available for each diamond compound, providing flexibility based on the specific application.

Diamond compounds, with their varied grades, colors and base options, provide a comprehensive solution for professionals in need of precise and superior polishing across diverse materials and applications.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

Ensuring Mold Steel Polishability

When working on a project that requires high-quality texturing or surface finish, using an electro-slag quality material may be the best option for mold steel.

Read MoreRethinking How to Polish

Internal process documentation helps polishers build upon experience and overcome surface finish challenges.

Read More

.jpg;maxWidth=300;quality=90)