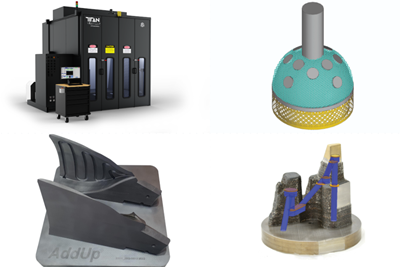

Addman Group was founded to bring additive manufacturing (AM) capabilities to American Industrial Partners’ businesses. The company now includes facilities across the country with capabilities ranging from metal and polymer 3D printing to precision machining and injection molding. Photo Credit, all images: Addman Group

Metal 3D printing and machining are complementary processes. But understanding exactly how the two processes interact is specialized knowledge that varies from part to part. Vertically integrating 3D printing and machining gives manufacturer Addman Group the ability to manage the whole manufacturing process, ensuring that 3D-printed parts meet customer needs. “Anybody can print you a paperweight,” says Bob Markley, executive vice president at Addman. “We want to give you a functional component that drives your program forward and makes you look like a friggin rockstar.”

Racing to 3D Printing

Markley is a self-described “recovering race car engineer” who founded 3rd Dimension Industrial 3D Printing outside of Indianapolis in 2013. “I know we’ve only really been around about 10 years now,” he notes, “but that makes us one of the most tenured companies in North America doing metal additive.” The company started with a laser powder bed fusion machine from 3D Systems, but it wasn’t long before the company expanded into machining. “We very quickly realized that almost everything we were printing needed to be machined in one way or another, either removal from the build plate, cutting threads, mating surfaces, tighter tolerance or surface finish refinement,” he says.

3rd Dimension’s first subtractive machine tool was a secondhand wire EDM. It was quickly joined by a manual mill, a manual lathe, two CNC mills and two CNC lathes, which it acquired when the racing team it had been outsourcing its machining work to closed down. The company also brought on a machinist.

Addman was formed in late 2020 as an additive manufacturing (AM) center of excellence for American Industrial Partners, a private equity firm that invests in industrial businesses and their portfolio of brands. 3rd Dimension was its first acquisition in early 2021. Since then, Addman has expanded its 3D printing technology and machining capabilities by acquiring several other companies. In late 2021, it added Domaille Engineering, which is a machining business with three facilities in Rochester, Minnesota; Glen Burnie, Maryland; and Wright City, Missouri. The Domaille Family of brands has since been folded into a new CNC line of business, called Addman Precision. Around the same time, it also acquired Castheon, a company in Thousand Oaks, California, that specializes in refractory materials such as niobium C103, a high-temperature alloy that’s particularly suitable for space applications.

If the part is determined to be best suited for 3D printing, the company does a “deep dive” to determine any potential manufacturing challenges and how to address them.

It also purchased Harbec in Rochester, New York, which Markley describes as “a mix of everything that we have,” including a diverse machining operation, metal and polymer 3D printing capabilities, tool and die making, and injection molding. Harbec also brings deep AM technologies experience to the organization, having implemented its first direct metal laser sintering (DMLS) machine from EOS sometime in the early 2000s, according to general manager Chris Piedici.

Addman’s latest addition is Dinsmore Inc., an Irvine, California-based business that specializes in fast turnaround polymer AM, from fused filament deposition (FFF) to selective laser sintering (SLS) for prototyping and production applications.

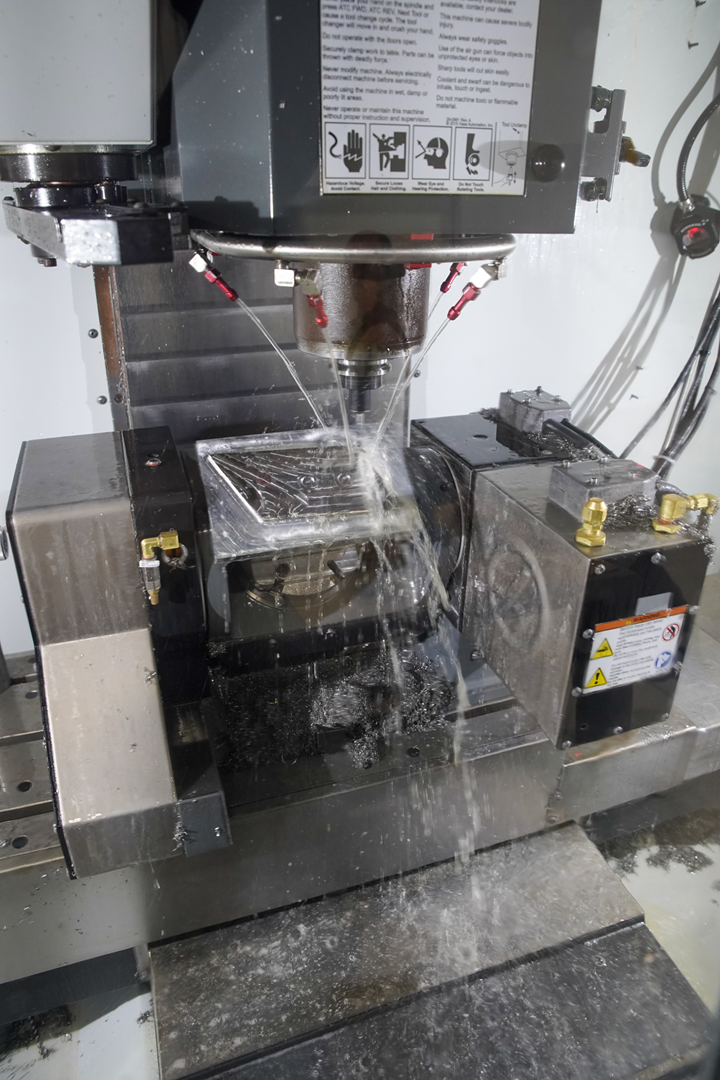

Between its facilities, Addman has access to a wide range of machine tools, including three- and five-axis vertical machining centers (VMCs), four- and five-axis horizontal machining centers (HMCs), CNC lathes, mill-turns, wire EDMs and grinding machines. This range of capabilities is especially helpful, because sometimes 3D-printed parts require specialized machine tools. For example, 3D-printed parts are getting larger. Because Addman has access to a five-axis machine with a large work envelope, it can produce large metal 3D-printed parts to complete.

Many 3D-printed metal parts require post-machining to remove support structures, add features such as threaded holes, and meet surface finish and tolerance requirements. Addman has both machining and metal 3D printing capabilities, making collaboration easier.

Parts and Requirements

As far as the types of parts being 3D printed, Markley says, “It’s a little bit all over the place. We see a few different value drivers.” Common themes are using 3D-printed parts as a replacement for castings, which have had “absurd” lead times for a while.

It’s also a good application for refractory materials, such as the ones Castheon deals with, that go into spaceflight components such as thrusters. Because these materials are hard to get and very expensive, it’s important to use as little of it as possible so that the “buy-to-fly ratio” is lower. These materials are also difficult to machine, and 3D-printed parts require less machining than parts made from stock. The Harbec facility also 3D prints mold tooling with conformal cooling channels.

Regardless of the material, process and end use, 3D-printed parts have requirements that need to be met. “Everything that would go into a machined part, we still have with the additive component,” Markley says. These include tolerances and surface finish requirements. If the AM process can’t meet these requirements on its own, the part needs to be machined. In fact, Markley says that most of the 3D-printed parts Addman produces need some form of post-processing.

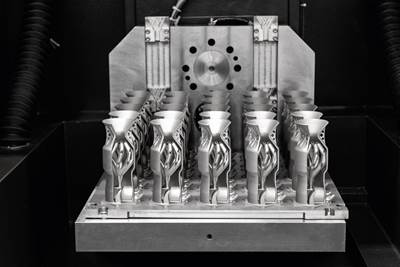

Before engineers at Addman’s Harbec facility hit print on a part or mold, such as these 3D-printed molds used to make personal protective equipment (PPE), representatives from all relevant departments (additive manufacturing, machining, tooling and injection molding) meet to discuss the project.

Collaboration

“For metal additive, all of the work happens in the front end before you ever start making parts,” Markley explains. Addman’s engineers establish the entire part production process from part design to finishing. Engineers request prints for the part and go through all of the notes to fully understand all of the requirements.

The first question they ask is, does the part really need to be 3D printed? This is another benefit to having machining and 3D printing within the same organization. “We’re going to help our customer find the correct manufacturing modality,” Markley says, whether that’s 3D printing and machining or just machining. If the part or volume is more suited to machining or injection molding than 3D printing, Addman can and will machine or mold it — the process could better suit the customer’s needs.

Engineers also consider whether these needs could change over time. Piedici points out that maybe AM is the best solution for short-term production, but machining or injection molding makes the most sense in the long term.

If the part is determined to be best suited for 3D printing, the company does a “deep dive” to determine any potential manufacturing challenges and how to address them. The team collaborates closely with customers throughout this process to ensure that the final parts meet their needs. “Surface finishes, tolerances, etc., can all direct costs, but they may or may not be critical to the customer’s end design,” Markley says. “So having a team that speaks both languages is certainly an advantage.”

Collaboration is also internal. Harbec assembles a team for larger projects that includes leaders from relevant departments (AM, machining, injection molding, etc.). “The communication — having a machinist under the same roof as my additive engineers — is gold,” Markley says. This is key because engineers have a number of considerations to take into account when machining 3D-printed parts:

- How will the part or parts be removed from the build plate?

- How will the support structures be removed — manually or via machining?

- Are there any features that can be used as datums for machining, and how will they be picked up?

- How will the part be held for machining?

- Does the part require extra stock? If so, how much and where?

These are all important to consider before printing because by the time a 3D-printed part reaches the machining process, it’s had a lot of value added to it and is therefore expensive to scrap. “It’s very different than starting from a piece of billet,” Markley notes. “So having that integrated solution is invaluable.”

3D-printed parts, such as this sample impeller, can be difficult to machine. They can also be difficult to hold, especially if they have thin walls or other delicate features.

Hold On

One particular challenge that requires extra consideration is workholding. “It becomes absolutely critical to make sure you have good reference points to pick up on that part and that it’s held solidly,” Markley says.

This becomes even more of a challenge when 3D printing is used to create certain features. “One of the key advantages of metal additive manufacturing is you only have to put material where you need material. So that tends to see extremely thin walls and low-rigidity parts,” he says. “So it’s not only how do you hold the component, but how do you hold that component still when you have such thin-walled components, and then make sure that you don't cut through your walls and you still have plenty of material left for the design to meet the requirements.”

That’s why engineers often design 3D-printed parts around fixturing, adding tabs or features to locate the part. Another option is machining the part while it’s still attached to the build plate, which is good for drilling and tapping holes or cutting thin walls when holding the part would be more difficult after removal from the build plate.

Addman also takes advantage of its polymer 3D printing capabilities. Not only can it 3D print polymer workholding for machining metal parts, it also 3D prints polymer versions of metal additive components, which it then machines to test workholding solutions. “Think of it as cutting aluminum part before you cut the titanium. It’s significantly less expensive to screw up a $30 plastic part than a $30,000 metal part,” Markley says. “That's just a good gut check to make sure that everything goes according to plan.”

This prototype part for Lockheed Martin was printed from 316 stainless steel, and, like many of Addman’s 3D-printed parts, required post-machining. This particular part required machining on all sides.

Consolidation

In addition to ensuring part quality, having all of these processes within one company enables customers to consolidate their supply chains. “We work with a wide variety of customers that don’t just want one manufacturing modality,” Markley says. “Our customers want an integrated supply chain solution where they’ve got one vendor number, they’ve got one person or a small team that they deal with, to figure out how to get parts.”

Addman is also able to consolidate all of its AM knowledge and expertise and share it across the organization. 3D-printed materials cut differently than materials produced through conventional methods. Markley notes that when a shop buys material, it gets a mill certification report that provides a certified record of the physical and chemical properties of the raw material. But when a shop 3D prints a metal part, it creates the material’s physical and chemical properties. For example, the printed material can have different grain structures because the cooling rate causes it to solidify differently than stock material. This gives printed parts different properties that cut differently than stock material, and understanding these details helps in machining these parts.

Another potential benefit to consolidation is shorter lead times. Harbec stocks a variety of metal powders, and, depending on the part’s geometry, can have 3D printers running within 24 hours. As an example, Piedici describes how, at the beginning of the COVID-19 pandemic, Harbec was able to quickly build molding tooling to make medical cassettes for COVID-19 tests. “We got geometry on a Friday and were molding parts on a Monday,” he says.

Harbec wouldn’t have been able to achieve this feat without having access to both additive and subtractive technology and teams that know how to collaborate. “That’s the potential of departments that can work together,” Piedici says. “You can solve really critical engineering problems within a short period of time, bringing people together to think both additively and subtractively.”

At the end of the day, AM is a way to make parts. “It's just like any other manufacturing method in that there are rules and limitations that we still have to abide by,” Markley says. “There’s just different rules and limitations.”

Reprinted from sister publication Modern Machine Shop.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Cutting AM Parts from Build Plate Turns Wire EDM Upside Down

GF Machining Solutions found it had to modify nearly every aspect of a wire EDM machine to efficiently handle the challenges of removing 3D printed parts from build plates. Here is a look at a machine tool developed entirely for the needs of metal additive manufacturing.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read More