Burteck President Pete Burgess stands amidst the shop’s arsenal of work cells essential to designing, engineering and managing plastic injection molds and continuing to grow internal part capacity. Photo Credit, all images: Burteck LLC

Burteck is no stranger to increased customer demand. Since opening its doors in 2010, the mold builder has continued to grow and advance, both in facility size and technology, to fulfill customer needs. What began with two people in 4,000 square feet grew into a 16,000-square-foot facility purchased in 2013. At its current state-of-the-art 40,000-square-foot building in Bloomfield, Connecticut, Burteck employs 35 people and specializes in designing, engineering and manufacturing plastic injection molds.

The need to increase capacity and consistently produce the most precise, long-lasting molds possible has translated to technological changes over the years at Burteck. Regarding its production equipment and strategies, the shop started with basic CNC machine technology and progressed to include EDM, high-speed milling capabilities and automated cells.

“Automated high-speed milling and EDM cells are the perfect fit for our operations,” Burteck President Pete Burgess says. “Once we had our first one on the shop floor, we realized that it was the future of Burteck production. So now, with every five-axis machine we purchase, it’s a given that we’ll pair it with automation. These work cells, along with our knowledge and experience, are how we continue to grow in terms of internal part capacity and our ongoing ability to win the work.”

According to Burgess, the shop’s recently added automated EDM and high-speed milling cells have increased the shop’s EDM RAM and milling spindle capacity by 33%. He expects that to increase significantly as the newer cells ramp up to full capacity. He adds that Burteck’s increased capacity furthers its ability to satisfy customers and resolve their pain points, such as speed of delivery, flexibility and reliability.

Every five-axis machine is paired with automation.

The automated cells help the shop run with a leaner labor force and enable its operators to go from one cell to the next because they are similar. In doing so, the cells increase the shop’s output.

Case in Point

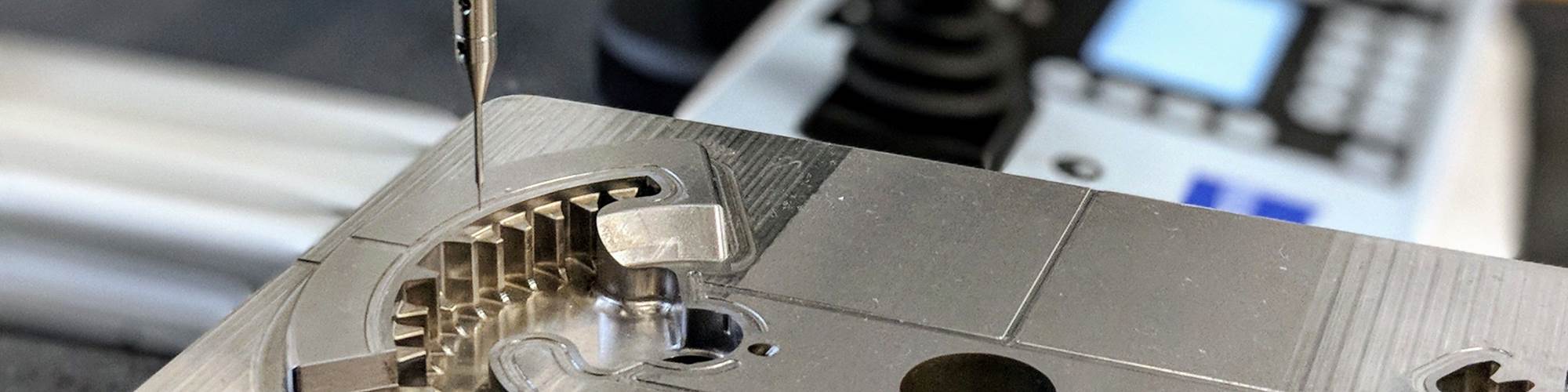

One of Burteck’s most recent cell additions encompasses two GF Machining Solutions high-precision Mill P 600U five-axis high-speed milling machines and a System 3R WorkPartner 1+ (WPT1+) compact pallet-changing robot for automated part loading and unloading. Thanks to the robust and thermostabilized polymer granite base platform of the Mill P 600U, the shop can hold part tolerances to ±5 microns and maintain positioning accuracy over extended machining times, deviating no more than 5 microns over 24 hours.

Currently, Burteck’s lineup of GF Machining Solutions technology includes four Form 20 sinker EDM machines, Cut P 350 and Cut 200 Sp wire EDMs and a Form X 400 paired with System 3R WorkPartner 1+ (WPT1+) automation. “Our Form X 400 EDM has opened our eyes to even more possibilities with running them automated because of their extreme accuracy,” Burgess says.

“Our customers ask us to produce molds that last five and 10 million cycles, and achieving that depends on how a mold is engineered and constructed — and, most importantly, how accurate the tooling is.”

While it’s experienced in working with OEMs and molders in specialty packaging and consumer products, as well as in many other markets, Burteck also produces many injection molds for the medical industry. As a result, mold requirements are highly demanding for customers in that sector, with very tight tolerances of ±0.0001 inch in some instances, according to Burgess. For this reason, the shop’s quality control systems check critical mold components between each operation. Those components go through a CMM inspection process that is also automated and that works directly off the part CAD models.

“We make an EDM electrode, for instance, and after machining it, we run it through a CMM,” Burgess explains. “If it’s good, we send it to the EDM cell, where it’s then used. Once the EDM process is complete, the mold detail will also go through CMM inspection to ensure it is produced correctly. We follow this same process for our hard milling operations.”

These high quality/precision standards are why Burteck uses machines from GF Machining Solutions. “They are extremely accurate and repeatable,” Burgess says. “Once we establish a good process, we know the GF machine will provide the much-needed consistency in holding tolerances.”

Regardless of mold type, Burteck customers want production molds that will last a long time. “When we say a long time, we don’t mean the current SPE/SPI class 101, 1 million cycle standard,” Burgess explains. “Our customers are asking us to produce molds that last 5 to 10 million cycles, and achieving that depends on how a mold is engineered and constructed — and, most importantly, how accurate the tooling is.” Mold longevity depends on the tooling material and the accuracy of that tooling. In addition, less part variation produces better-molded parts with less mold qualification times.

Burteck moldmaker Jim Morgan works on molds with very tight tolerances, so quality control systems are essential.

Original mold accuracy also figures into the spare parts that Burteck provides. When mold components are made precisely to tolerance, any replacement part Burteck supplies are guaranteed to fit. This eliminates the time and hassle of shipping back worn or damaged parts for replacement part referencing.

Burteck will also continue to diversify. “We were heavily weighted on supplying the market with molds built from our Asian side of the business,” Burgess says. “Our long-term strategy is to achieve a balance between Asian and domestic, and the advance of our Bloomfield operational capacity plays into attaining that goal.”

The future for Burteck, according to Burgess, is continued growth and building more molds for customers who want domestic suppliers. “Much of that growth will dovetail with technology from GF Machining Solutions in the form of advanced machining and automation that will enable us to do more unattended production,” he adds.

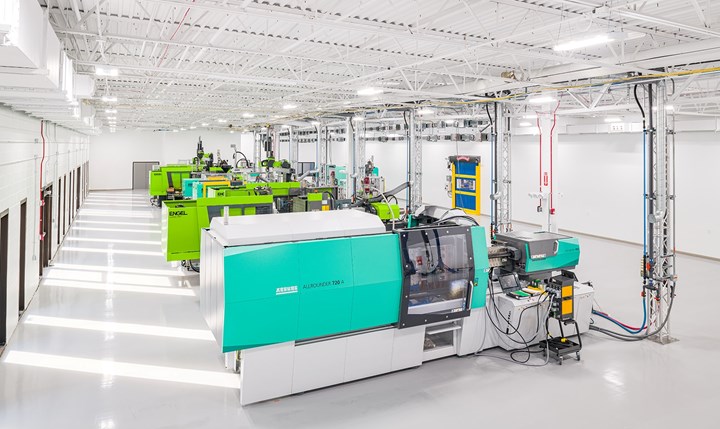

Burteck also performs in-house mold testing for customers on its injection molding machines at the new Bloomfield facility. Customers that are purchasing a molding machine or retasking existing equipment for a new molding project can have the complete turnkey systems engineered by Burteck. The facility is equipped with a central chiller system, flexible electrical grid and dedicated technical resources. Burteck has the ability to not only build production molds, but also develop an entire molding work cell in house as a cohesive manufacturing system.

Complete turnkey systems engineered by Burteck.

Related Content

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

Burteck Provides Total Mold Solutions, Including LSR Molds

Burteck LLC adds LSR molds to its plastic-injection moldmaking capabilities along with a new molding technology center.

Read MoreStriking a Balance with Global Production

Due diligence and the right business model gives Burteck the flexibility to reap the rewards of overseas mold manufacturing while limiting potential drawbacks.

Read MoreExtra Large Wire EDM Capacity Places Shop on Path for Growth

The constant need for larger, more efficient machining capability pushed Extreme Wire EDM Services to approach GF Machining for a larger wire EDM solution.

Read More