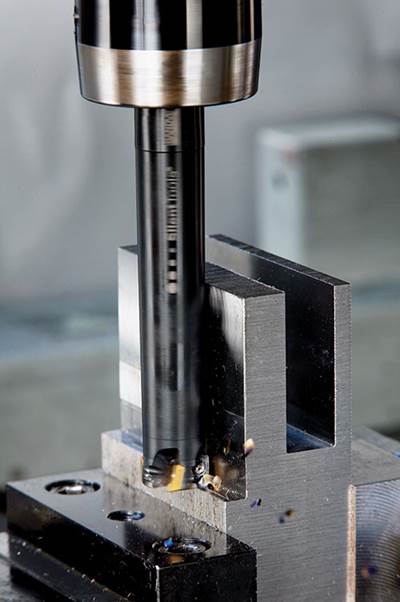

Integrating and learning how to use digital tools can help shops practice predictive maintenance and improve tool performance. Photo Credit, all images: Sandvik Coromant

Today, there are many innovations in cutting tool technology. Whether a seasoned pro or novice, these technologies are new for everyone. New edge preps, coatings, cutting materials, digital capabilities and application methods are differentiators that help shops remain competitive if their moldmakers know how to use them properly.

While moldmakers who are entering the field for the first time may have already encountered some of these advancements in a vocational school or technical college, putting theory into practice on the job isn’t always easy. In addition, as the industry changes, all moldmakers must continue their education to help keep their shops and their skillsets up to date.

Modern Cutting Tools Enhance Quality

Through continued education, moldmakers can master the latest technology and tools that help shops create higher quality molds quickly and efficiently

To accurately achieve the most challenging features in a mold base, moldmakers must choose the cutting tools and toolholders that are most appropriate for the job and know how to use them. In addition, toolholders must have clearance, while cutting tools must withstand cutting forces generated by hardened material and easily access any part of the mold.

To get deep inside a mold or cavity, moldmakers want to choose durable tools that have extended length-to-diameter ratios that can reach far beyond the spindle interface and provide a superior surface finish. Some of the latest solid round tools have very small diameters or complex shapes or forms on the cutter, creating features within the mold cavity. Continued training gives moldmakers the know-how to improve their decision-making and use the latest tools to efficiently machine high-quality molds.

If a cutting tool and toolholding system isn’t the right choice for the job, doesn’t have clearance or isn’t set up correctly, a moldmaker won’t be able to get the tolerance and accuracy needed to execute a particular radius or angle within the mold base, and the quality of the components it produces will suffer.

To remain competitive, it’s essential that shops take modern cutting tool technology, apply it properly, use tooling how it was designed to be used and look at their manufacturing operation from the cutting edge back. The way to do this is through continued training.

Hands-on training is an effective way to learn the theory behind modern cutting tools and properly use them. Training like this is different from a technical school or apprenticeship because of the perspective on modern cutting tools and what makes modern cutting tools work. The theory is often presented through interactive conversations or presentations in a classroom. The hands-on part is then conducted in a shop environment where participants practice techniques and methods on real machines.

If travel isn’t possible, some training centers also offer virtual classes or self-paced, online learning to help moldmakers upskill from wherever they are. Participants can access courses through a phone, computer or tablet and learn new skills when it’s convenient for them.

Digital Machining Improves Productivity

Hands-on training teaches moldmakers the most effective ways to use the latest cutting tools confidently.

Mold builders have evolved to highly digital environments. While moldmakers continue to focus on cutting tools, they’re now also focused on digital tools that can improve shop productivity and the data they can collect. For example, machine performance metrics offered by some cutting tool suppliers collect data from the machining operation and allow machinists to gain insights about machine utilization, stop causes, alarms and faults that could decrease productivity.

Mold builders must understand how to properly use digital tools and analyze the insights from the gathered data. Training helps ensure they can confidently use those insights to act in tangible ways that make a difference on the shop floor—from practicing predictive maintenance to improving tool performance.

Many training facilities include digital technology in their classes, such as smartphone applications and cloud-based software, as part of standard training. For example, during one hands-on practice on the shop floor, participants download an app and use it to calculate all the parameters to run a part. Incorporating digital tools transfers essential skills and makes classes more interactive and engaging.

In addition to standard training, customized training can help shops further their digital transformation journeys. For example, a shop may have specific questions about something as straightforward as CAM and verification tools, or it may simply want to know where to start. Customized training can break down complexities so shops can understand the possibilities of what they can do to improve productivity and reliably achieve business goals.

Cutting tool training centers should provide participants with hands-on access to a range of CNC machines.

Five Factors to Consider When Evaluating Training Options

There are specific criteria to consider for those moldmakers and shops searching for training that directly benefits their businesses. Some are obvious, such as deep experience and CNC machines on the training floor. Other criteria, however, may not be as apparent. These include digital live machining (DLM) capability, a worldwide network of specialists and R&D investment.

-

Deep Expertise

A cutting tool manufacturer’s training center often has an advantage simply due to the number of experts on hand. In addition to their full-time, dedicated instructors, training centers can bring production, engineering and R&D experts into the classroom. These experts are the people making the actual cutting tools, so they intimately know how the tools are supposed to work and precisely what they do.

If a class wants to learn about grades and edge prep technology, the instructor can ask the grade development specialist to speak about grade development. Some training centers are even connected to their production unit, so instructors can take participants into the shop to see cutting tool manufacturing in real time.

-

CNC Machines

For onsite classes, a facility must have an advanced machine shop with different CNC machine tools for hands-on application of metal-cutting operations. Some training centers even put cameras on each machine so that participants can see real-time processes up close rather than huddle around a tiny window on the front of a machine tool.

-

Digital Live Machining (DLM)

DLM allows participants to attend training virtually, while feeling like they’re in the training center. DLM enables the real-time footage from machine cameras to be broadcast through a video conferencing program. Depending on the conferencing program used, presenters can switch between lecture, presentation and DLM demonstration modes. This can be ideal for mold builders that want to upskill their workforce but don’t have a big travel budget. They can project the training in a conference room and receive live instruction.

-

Worldwide Network of Specialists

Some training facilities are part of a more extensive network of global centers, each with its machining specialties. With the help of DLM equipment, instructors can call into other centers to view machining demonstrations to share capabilities they don’t have on site. This multiplies a single center’s capabilities, providing a broader range of skills to participants and more significant benefits for shops.

-

R&D Investment

High-quality training centers don’t simply teach the same things over and over. Instead, they invest in modern cutting tool innovations and the continued education of their teaching staff. As a result, they not only teach the latest technologies, they drive industry innovation.

Mold builders should take a look at standard and customized training programs.

Continuing Education Moves Mold Building Forward

The simplest way to find quality training that focuses on modern cutting tools is to check in with your cutting tool provider. Some providers list their training schedules on their websites. If preferred training isn’t available, check with your sales team to see if your provider offers customized training.

To remain competitive, it’s essential that shops take modern cutting tool technology, apply it properly, use tooling how it was designed to be used and look at their manufacturing operation from the cutting edge back. The way to do this is through continued training.

When moldmakers step out of their day-to-day environment and learn how to apply modern cutting tools most productively, it can help the shop become more profitable. Conversely, when shops aren’t on the cutting edge of what’s new in the industry, they could miss out on advantages that drive their business forward.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHow to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreRead Next

Scrap the Tap?

Thread milling is often faster and more accurate than tapping in tough mold applications.

Read MoreRelease the Entire Potential of Your Machine Tool Investment

Making tooling a part of your machine tool purchase via a tooling certificate can save you time and money.

Read MoreIncrease Process Security and Minimize Risk

Staying competitive in the growing automotive market comes down to quality, productivity and cost per component, and all three can be accomplished with the right set of tooling solutions.

Read More

.png;maxWidth=300;quality=90)