Connected solutions minimize errors, boost competitiveness, expedite time to market and enhance control over product quality throughout the entire process. Source (All Images) | Hexagon’s Manufacturing Intelligence Division

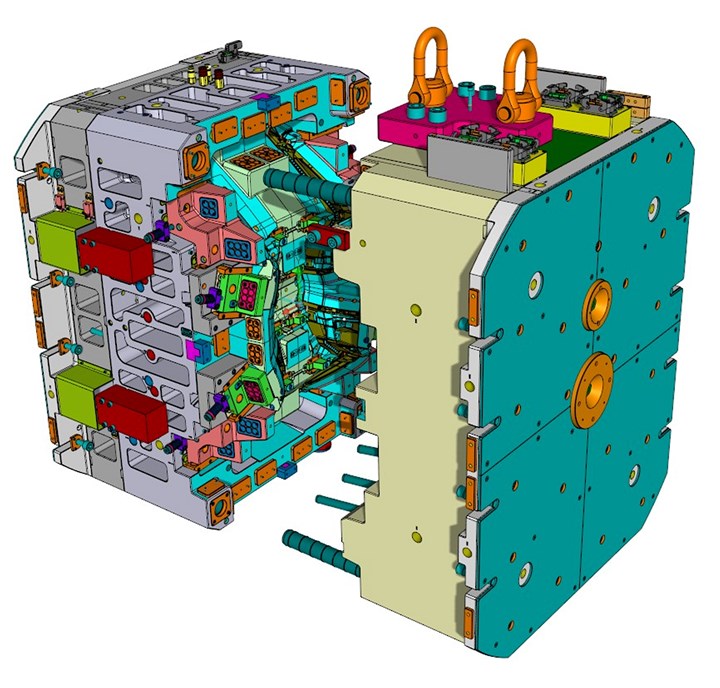

As production deadlines tighten and workflows continue to become more digitized, the connectivity of software used to produce plastic injection molds is rapidly becoming a requirement. Among other benefits, linking solutions from design through manufacturing ensures the use of a single source of design data from start to finish and eliminates data loss caused by repeated file transfers.

Connected systems enable seamless data sharing.

In cases where systems are incompatible, helpful data may even need to be omitted so that a file created in one software can be processed in another. While a skilled moldmaker can fix problems caused by missing data and system incompatibility, less experienced workers struggle to repair gaps in information that could be prevented by improved connectivity.

Connected systems are also a productivity boon to shops with different departments that work simultaneously on the same projects because connected solutions enable seamless data sharing. For example, when a change is made to a design file, that change is applied across the board so that everyone working on the file has access to identical information.

Here are five steps in the moldmaking process that benefit from being a part of a connected software solution:

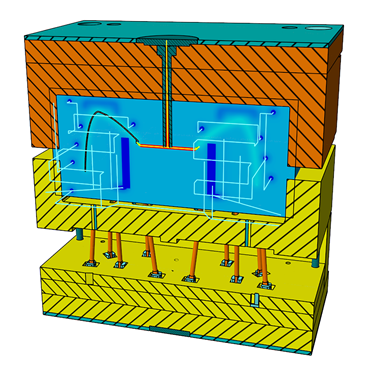

1. Flow Analysis

Less is more when selecting flow analysis software as part of an interoperable solution. While a market leader in flow analysis software can deliver excellent predictive tools, the exhaustive number of tools provided and the expertise required to use them correctly can overwhelm a moldmaker who simply needs to know if their mold will perform as designed.

Essential for handling new and unfamiliar materials, flow analysis software should offer feedback that is clear and practical to utilize.

Software that provides easily digestible feedback reduces error and is crucial for working with new and unfamiliar materials. Without reliable software capable of indicating, among other factors, that the cooling channels are in the correct location and the material is at the right temperature, it’s impossible to know if a design will produce the desired results without expensive and time-consuming physical tryouts.

Flow simulation software developed for moldmakers helps simplify complex cavity, runner system and cooling line design. It offers tools for optimizing runners, providing thermal and final part shape analyses and identifying the fastest possible cycle times. Connected solutions make it easier to apply design insights gained from flow analyses because it’s much faster and easier to work back and forth between interoperable design and flow analysis systems.

2. Reverse Engineering

Because skilled moldmakers are also adept reverse engineers, no solution for plastic injection mold production is complete without interoperable reverse engineering software. As part of a connected solution, software dedicated to reverse engineering enables moldmakers to reverse engineer, design, simulate and produce components using software with common interfaces and workflows.

Software designed for reverse engineering is specifically tailored for point cloud manipulation.

Reverse engineering software is used to import point clouds from scanning devices, automatically create meshes, perform dynamic wireframe grid construction and automatically create surfaces. The benefit of using reverse engineering software instead of a standard CAD system is that it is developed specifically for working with point clouds.

While CAD systems do get the job done, reverse engineering tools are better at helping control the quality of developed geometry and provide functions for improving and repairing meshes and creating and trimming surfaces and solids.

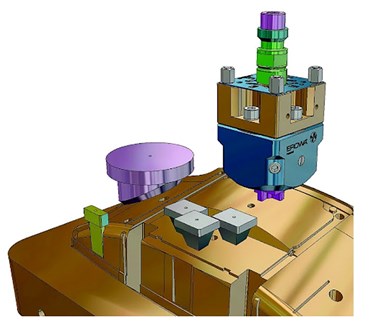

3. Electrode Design

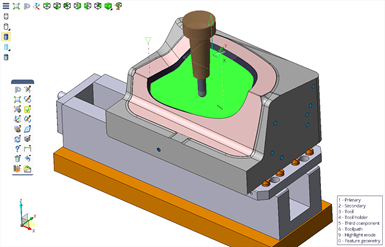

EDM electrode design is one of a moldmaker’s most complicated and time-consuming tasks, so software dedicated to its automation is a significant time saver. As part of a connected solution, it offers the same benefits as design, simulation and reverse engineering software by ensuring data can be easily shared within the connected system.

Software that automates electrode design and provides simulation and collision checking guarantees the first-time functionality of electrodes.

Software that automates electrode design helps design electrodes and their holders for the manufacturing of detailed and difficult-to-machine mold features. Systems that offer comprehensive holder design, simulation and collision checking ensure that electrodes will function correctly the first time they are used.

While automating design is a clear benefit for less experienced staff, even experienced designers can benefit from systems that offer knowledge-based automation technology.

4. Component Selection

When customizing a connected solution to fit a company’s needs, it’s important to consider tools that relieve the burden of time-consuming and repetitive tasks. Among those tools is mold design software that simplifies the selection of digital mold components and their integration with existing projects.

Easy access and integration of digital mold component models into in-progress designs speeds up the design process and ensures flawless assembly of final products.

Mold design entails constructing full assemblies that include in-house and supplier components like ejector pins, guide bushes and retainer plates. The ability to easily access and add digital models of these components to in-progress designs accelerates the process and ensures that final products are assembled perfectly.

Mold design software that provides direct access to cloud-based component databases and digital models eliminates flipping through paper catalogs or visiting websites to find and download models of single components and full assemblies.

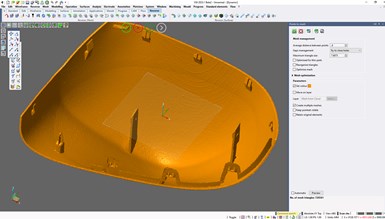

5. Design Data Transition

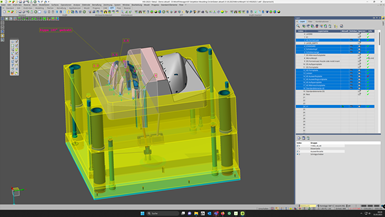

Connected solutions in which mold designs can be sent straight to CAM software improve efficiency and instill confidence that jobs will be accurately and safely produced. While the ease of importing CAD data has improved over the years, interoperable systems further ensure a painless transition from design to CNC manufacturing.

CAM solutions tailored for plastic injection mold production should offer tools for machining deep cavities and simplifying complex multi-axis machining.

A CAM solution developed to produce plastic injection molds should provide tools for machining deep cavities and for simplifying complex multi-axis machining. Some systems are also capable of automatically converting a three-axis tool path to a five-axis tool path; this helps manufacturers reap the benefits of short, rigid tools that eliminate vibration for better part quality and surface finish.

Success at Every Stage

Connected solutions for plastic injection mold production increase productivity by providing mold-specific tools that maximize efficiency at each stage of manufacturing and help streamline collaboration. Using the tools of a single systems provider simplifies software integration and support, while uniform software interfaces and workflows make it easier to train employees. These advantages add up to reduced error, increased competitiveness, shorter time to market and improved control over the quality of projects from beginning to end.

Related Content

How to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreTake Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreHow to Use Automation to Minimize Mistakes and Speed Mold Build Process

A guide to capturing and reusing company knowledge and experience with software automation.

Read More