Incremental growth and refinement are vital components to Eden Tool and Eden Manufacturing's growth strategy. Source (All Images) | Creative Technology Corp.

“Our strategy is taking on programs in crisis because it forces us to be agile and innovative,” says Eden Tool and Eden Manufacturing President David Tomic. I thought about how fitting that statement is, considering his team experienced a personal crisis of its own, faced it head-on with a consistent strategy and innovated in myriad ways throughout the business.

Eden Tool and Eden Manufacturing have experienced big changes, but the team is holding firm in its core identity: high-quality, high-precision critical parts manufacturing built upon solid tooling and manufacturing fundamentals.

Three years after my initial visit to Eden Tool in New Freedom, Pennsylvania, I arrived on-site and discovered that a lot had changed. However, the company’s core identity remains intact: a high-quality, high-precision critical parts manufacturer founded on solid tooling and manufacturing fundamentals. Eden’s strategic plan is the same: Develop good people, open up capacity, offer great service to current customers and provide dependable solutions to programs in crisis. The changes — some expected and some not — only accelerated its foundational business and succession plans. The key to success so far has been incremental changes in business processes and employee roles — with a lot of repetition and determination.

“Quality can be impacted when growing, so we are growing incrementally and refining as we go. We’re not just going to bring in a ton of people because we’re getting a new program. It must be holistic and long-term focused,” says Tomic.

“We’re not looking to grow. We’re not looking not to grow. We’re going to develop a good foundation and that will take us wherever we’re going and show us which doors to go through first, second, third or we’ll wait for a manufacturing program in crisis or a specific customer need and play it out.”

Process: Expanded Facilities and Capabilities

Eden Tool continues to use a predictable manufacturing philosophy rooted in its hard milling capabilities.

Eden Tool is a 19-person, Class 101 plastic injection mold manufacturer founded in 2000 based on “doing tools differently,” mainly for the medical industry. Today, the shop remains relevant and highly effective, building upon a predictable manufacturing philosophy rooted in its hard milling capabilities.

Then, in 2019, a need for capacity in the market triggered the launch of Eden Manufacturing to provide production manufacturing capabilities for critical and detailed medical and surgical devices in a separate building, next door to Eden Tool. Tomic started designing the building in December 2019, but the uncertainty of the pandemic created delayed construction. The building was completed in July 2023 and currently employs eight people.

An ISO-certified quality management system is the backbone of the company’s ability to produce these complex parts in a precise, efficient and predictable manner. Eden Manufacturing puts Eden Tool’s predictable manufacturing philosophy into practice by implementing robust production solutions — including injection molding, machining (Swiss, EDM and five-axis CNC) using the latest machine, robot and automation technologies in a 24/7 lights-out environment — to manufacture these complex parts.

“Hard milling is at the heart of predictable manufacturing in moldmaking, but when you apply this principle to the production injection molding and metal manufacturing process, it’s more philosophy-based,” explains Tomic. “That’s because injection molding has not yet had a disruptive technology like hard milling that radically revolutionized how you can design and build a mold.”

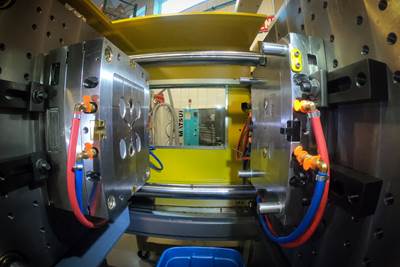

The new building for Eden Manufacturing is specifically designed for small press/part molding with every inch utilized.

Having Eden Tool next to Eden Manufacturing offers an advantage to injection molding projects because the teams can work together to build, validate and service injection molds quickly and effectively. They also build custom fixtures and support equipment for its additional in-house manufacturing capabilities.

The new building is specifically designed for small press/part molding. Every inch is utilized, with a full overhead crane and a ISO 8 clean molding room that can house between 10 and 14 presses of various sizes and configurations (165-ton to micro molding). Each press has a boxing line or automation where Eden Manufacturing’s team can run a 24/7 lights-out operation.

“It’s with a great team that focuses on the manufacturing details and consistently inspects in-process parts that makes us all proud to put our Eden Manufacturing name on every box of parts we ship out,” says Tomic. “We have tools that in less than a year have over 1,000,000 cycles, and we run 24/7.”

Eden Manufacturing’s flexibility and available floor space make it scalable, so the team is looking forward to future growth opportunities in capabilities and capacities. “What’s exciting now is to see it all come full circle. As our tool shop gets better, it makes our molding better, and as our molding gets better, it makes our tool shop better,” says Tomic.

A cultural shift has taken place with communication. Team members now have more influence as opposed to the previous top-down approach. Each department and employee has priorities, but they work together as a team.

People: Succession, Mentorship, Leadership

In December 2021, after managing the impact of the pandemic, Eden Tool founder, Mike Eden, passed away. This immediately impacted Eden Tool because it had grown significantly, and Mike was the management team.

“Mike and I already had a management transition plan to support this recent growth in mind, but now we had to turn survivalist,” explains Tomic. “We quickly named this leadership team and I prioritized mentoring and empowering them.”

This was a big transition in the working culture. Traditionally, if there was a final decision to be made, Mike made it every time despite having people on the shop floor with the experience and technical knowledge to make those decisions. Now, the team had to trust their experience and use it collectively. This required increased communication and collaboration amongst this new leadership team.

“It has been a cultural shift in the way we communicate because the team members have more influence as opposed to top-down. Each department and employee have their priorities, but we work together as a team. Everything for us is built on a big-picture view between both companies,” explains Tomic.

With Mike Eden's unexpected passing in 2021, the company was forced to implement a two-year plan in two months. The team trusted the plan and supported the path forward to make Mike proud.

Eden Tool basically took its two-year plan and implemented it in two months and the team had to trust the plan. “Gratefully, we had great buy-in from everyone,” Jake Eden, Mike Eden’s son, says. “The team wanted to make my father proud.”

Mike’s passing reaffirmed customer commitment to the company and the new leadership group as they made significant investments in the facility and equipment (CNC, grinder, overhead crane, wire EDM). All of these investments signaled to their customers that the Eden Group was not going anywhere, thereby becoming more confident in the company’s strategic plan, enabling the team to be awarded some large tooling programs.

Dave Tomic (left) and Jake Eden (right) bring different perspectives to the table as they work in and on the business together.

Tomic’s current role in Eden Tool is providing strategic leadership while mentoring Jake on how to run the business and supporting the leadership team to take on more responsibility. “I’m still very involved, but our leadership team is great and they are the face of most of the day-to-day customer/supplier communication,” says Tomic.

His role is to guide the team on how to assess risk and make decisions, and Jake will continue to learn the business through project management where he can continue learning tooling and manufacturing processes while developing a rapport with customers and suppliers. The big switch for Jake is going from engineering to learning to operate a business. “I’m passionate about what I’m learning and I’m engaged in the business,” says Jake.

Tomic is excited to see where the company will be in 5-10 years because of Jake’s very different perspective, including understanding business math and learning how business money works. “For example, current discussions with Jake involve the strategies of buying a particular machine and how this will provide a competitive advantage for us over time,” says Tomic. “This is a fundamental change in the shop environment. I wasn’t exposed to those aspects of the business until my 30s. For example, how to calculate program costs and returns, how to invest in capital equipment and what to look for in lease and legal terms. This knowledge early on will help Jake make better decisions for the company. It’s all about experiential learning.”

Process, people and practice are the cornerstones of leadership development and company growth at Eden Tool and Eden Manufacturing.

This learning includes peer leadership development, which Tomic and Jake decided to formalize with a consultant — an outside group of various business leaders who meet with them once a month for a facilitated discussion about the soft side of running a business. “This is a place where we can work on the business not always in the business. We also meet as a leadership team internally where we take some time to work on various leadership topics as well as professional development topics,” says Tomic.

When considering new employees, the Eden Group conducts a DISC analysis for key roles but also looks for high aptitude, curiosity and a desire to learn as opposed to manufacturing experience. “A lot of Eden’s new hires have no connection to moldmaking and most are from personal recommendations or introductions. These become our best team members,” Tomic says.

However, today the Eden Group’s focus is not only on process and people but on practice. Ongoing technical training is vital to the company’s overall success as it provides the foundation for a well-rounded team that is diversified in both age and experience. “Eden partners with Roustis, Tooling U and our local manufacturing association for training support in addition to specific internal training programs, building a team with some of the best work ethic and training in our area,” Tomic says.

Planting the Seeds

“We’re not looking to grow. We're not looking not to grow. We’re going to develop a good foundation and that will take us wherever we’re going and show us which doors to go through first, second, third or we’ll wait for a manufacturing program in crisis or a specific customer need and play it out,” says Tomic.

For example, Eden has always wanted to add Swiss machining, micro molding, overmolding, assembly and packaging, but the first step was injection molding. It’s all about incremental change. Tomic believes that if you’re strategic and consistent, it will all play out in time. True to these words, in 2023, the company added Swiss machining and overmolding capabilities.

“We demonstrated we could lose a key person and still become stronger as a company in the end. That's what increases actual business value."

The Eden Tool and Eden Manufacturing businesses — due to unfortunate trial and circumstances — are worth more today because of these trials and circumstances. “Forced change creates opportunities if embraced,” says Tomic. “We were forced to put systems in place quickly, which ultimately increased the overall business value. We demonstrated we could lose a key person and still become stronger as a company in the end. That’s what increases actual business value.”

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreMMT Chats: Predictable Manufacturing and Incremental Gains Can Transform Moldmaking

MoldMaking Technology Editorial Director Christina Fuges catches up with the president of Eden Tool and Eden Manufacturing, Dave Tomic. We talk about predictable performance in moldmaking and the value of small incremental gains in an organization versus big change via disruptive technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)