Maintaining High Levels of Initial Machining Accuracy

While planning for the future, Mold Craft is disposing of less capable equipment taking up valuable floor space and replacing it with profitable, state-of-the-art machines, such as its latest investment.

While planning for the future, Mold Craft--a manufacturer of high production molds featuring tight tolerances and true cavity insert interchangeability--says it will dispose of the equipment that is less capable and taking up valuable floor space, and replace it with profitable, state-of-the-art machines that will enhance its customer offerings while maintaining aggressive delivery dates.

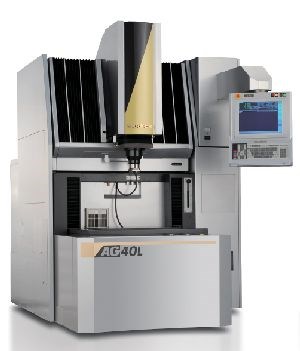

Investing in this Sodick AG40L sinker EDM was a big step in the process of bringing new technology into this shop. Now Mold Craft is prepared to serve more customers with higher technical requirements and meet tighter tolerances and deadlines.

“With this EDM's linear motor technology--which provides high feed rates and acceleration resulting in naturally even flushing--high levels of initial machining accuracy can be maintained for long periods of time,” says Justin McPhee, vice president of engineering. “We needed a machine that was capable of tight tolerances with extreme corner radius accuracy and superior surface finish, and the Sodick AG40L has demonstrated these capabilities."

Related Content

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.