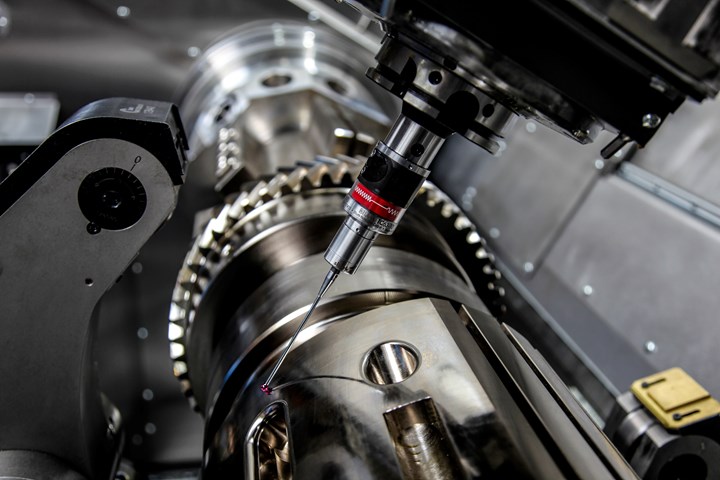

Touch Probe Delivers Fast, Precise and Reliable Mold Inspection

High scanning and probing speeds and a high-precision measuring mechanism characterize Blum-Novotest’s Digilog test probe systems.

Share

Read Next

Blum-Novotest, a manufacturer of innovative, high-quality measuring and testing technologies, features its Digilog test probe systems that enable high scanning and probing speeds in the hard-use, high-output molding environments. Complex contours can be monitored in series at up to 2 m/min to increase productivity while maintaining strict specifications.

Digilog TC63/64/76 probes provide high-precision digital measurements and lightning-fast analogue scans, according to the company. They feature BRC radio technology and are particularly suited for mold inspection. By analogue scanning the workpiece surface, machining errors are quickly and reliably detected. Shark360 technology, a high-precision, face-geared measuring mechanism, delivers defined deflection direction and constant deflection forces for maximum accuracy. The TC63 Digilog probe is the modular version that enables extensions and elbows attachments. The TC76 Digilog is a hard-wired alternative.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.