One-Stop Shop Simplifies Custom Surface Textures, Mold Performance

NPE2024: Standex Engraving Mold-Tech specializes in managing every step of the project process, from texture design and engraving to preparing the tool for production.

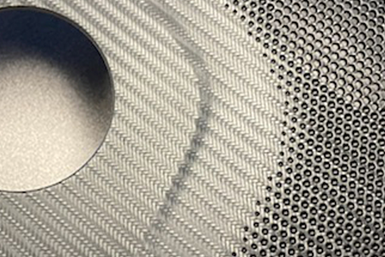

Texturing performed on a front car door speaker grill. Source | Standex Engraving Mold-Tech

Through its One Partner Solution, Standex Engraving Mold-Tech offers services and technologies that support projects from the beginning to end — from specialized finishing through to manufacturing support.

The company’s services start by designing a custom texture tailored to a customer product, verifying those grains on the product, engraving the tool and then optimizing that tool for streamlined manufacturing. Standex Engraving Mold-Tech highlights the seventh-generation Ford Mustang as a key example of its capabilities, demonstrating its laser engraving technology throughout, but in particular on the front door speaker grill (shown at right), which presented a challenge.

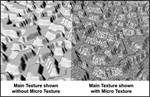

Ford’s front door upper speaker mold was laser engraved with a carbon fiber texture onto a steel surface consisting of both benched and EDM in a seamless fashion. Standex Engraving notes the preciseness of laser engraving, which can control the grain locations around featured surfaces and shut-offs. The end result camouflages the speaker holes within the texture itself, eliminating the need for framing or a separate grill piece required.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)