Five New Design of Experiments Lessons Available

Kruse Analysis provides part designers, mold designers and senior process engineers with five new sessions on the subject of design of experiments (DOE).

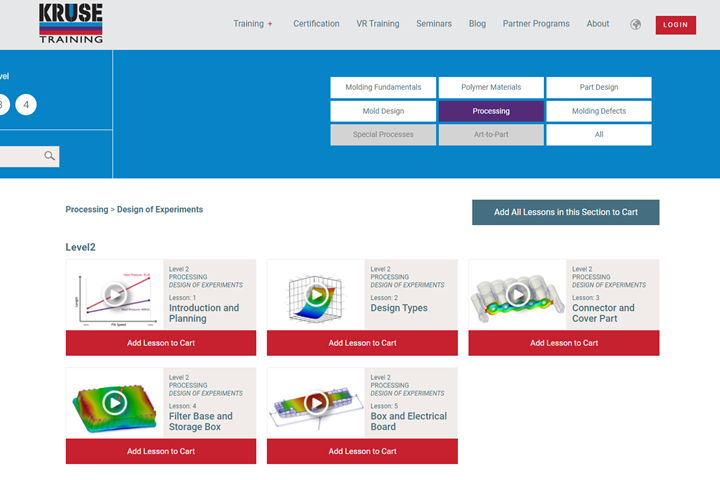

Photo Credit: Kruse Training

Kruse Training, an online knowledge and training solution for part designers, mold designers and senior process engineers, has made five new design of experiments (DOE) lessons available. This includes Introduction and Planning; Design Types; Connector and Cover Part; Filter Base and Storage Box; and Box and Electrical Board.

DOE is a mathematical tool that can be successfully applied to areas of new mold trials and troubleshoot potentially challenging processes. Experimental design techniques can be used by anyone with a fundamental understanding of injection molding. This section covers the fundamentals of DOE and how to apply a DOE strategy for molding quality parts.

Kruse Training’s new lessons break down the basics of running a DOE and then take students through specific examples of how to apply the theory to real-world examples. All sessions are clear, concise and walk students step-by-step for a complete understanding of concepts.

Goal of the DOE lessons are:

- Learn the theory and framework of establishing a DOE strategy and how to apply this knowledge to real-world molding examples.

- Learn the five stages of conducting a DOE strategy and how to utilize various charts and graphs to analyze the data.

- Learn about several design types and how they can be applied to DOE.

Kruse Training lessons can either be purchased individually or by sets on a specific subject.

Related Content

-

VIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

-

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

.png;maxWidth=300;quality=90)