DMG/Mori-Seiki Hosts Innovation Days

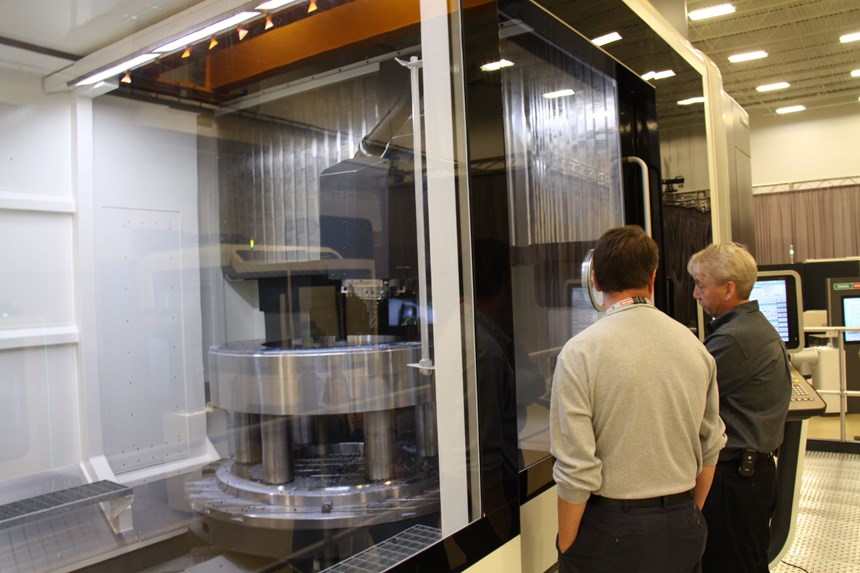

Leading machine tool manufacturer DMG/Mori-Seiki welcomed customers, partners, employees, and other industry professionals to Hoffman Estates, Illinois for Innovation Days, a three-day event featuring seminars, machine demonstrations, and expert presentations, held May 3-5, 2011.

Share

Read Next

More than 2,000 guests converged at the company’s US headquarters, which features an expansive showroom where more than 40 machines were on display.

Mori Seiki President Dr. Masahiko Mori and newly appointed DMG / Mori Seiki USA President Mark Mohr were both on hand to greet customers and guests. The event also included plenty of access to the company’s engineering staff to answer specific inquiries about machine capabilities from current and prospective customers.

Session Highlights

Each day featured presentations from DMG/Mori-Seiki engineers and executives partnering with some of the company’s largest customers from across the country, including Boeing, Siemens, and Sandvik Cormorant. Day-by-day highlights addressed the event’s “Innovation” theme with forward-looking sessions designed to jump-start customers’ productivity.

Tuesday, May 3: The Innovation Days kick-off session featured Boeing Company Manager Craig Charlton, along with DMG/Mori-Seiki Sales Manager Deitmar Haberlag, who discussed some of the new technologies the aerospace giant is using to improve design, production, performance, quality and affordability. New technologies covered included advanced prototyping, machining super-strong alloys for thinner and more complex structures, and working with new composite materials.

Wednesday, May 4: It was standing-room-only for the second day’s opening session, where Tim Smith, CFO of Smiths Machine in Cottondale, Alabama discussed how improved set-up efficiencies and a focused effort toward standardizing its machines and processes helped his company grow 300%, in spite of a challenging economy. “There is no complacency – you’re either growing or dying,” he told attendees.

Thursday, May 5: With applications in diverse industries including dental, medical, aerospace, die & mold, tooling, and automotive, new laser and ultrasonic machining technologies offer new capabilities that can help customers amp up productivity and differentiate their business.

Machine Highlights

More than 40 machines crowded the facility’s display floor, including several of the company’s new X-Class machines and a range of 5-axis machines. Machines of particular interest to moldmakers include the following:

NVX 5080. This high-performance, high-speed vertical machining center features a coolant-circulation option for increased thermal stability. The machine has been engineered for improved rigidity and also features an option for high-precision contour control and expanded memory capabilities. “Point-to-point cutting generates huge programs, but the NVX can handle them,” applications engineer Henry Llere told us. “That faster information processing is a definite advantage for moldmakers.”

(New) DuraVertical 635eco. Innovation Days marked the public debut for this vertical machining center, which features a powerful spindle and low-maintenance performance. The unit’s MAPPS IV high-performance operating system combines industry-leading hardware with advanced application/network systems and 3-D simulation.

LaserTec 40 Shape. Non-contact laser technology, previously used extensively in aerospace and medical manufacturing, is also now saturating the industrial and moldmaking markets, according to Field Service Engineer Joe Magiera. This machine is capable of precise and high-quality shapes, cavities, 3-D laser engravings, and complex parts with steep walls. The use of 3-D CAD files eliminates electrode production and tool-wear costs. “About three-quarters of the customers considering this machine are looking at it for its moldmaking applications, as an alternative to EDM,” Magiera reported. “No tool wear means consistent performance day in and day out.”

Ultrasonic machines. The 5-axis Ultrasonic 10 (which is so compact it fits through a standard door) and the new Ultrasonic 20 linear both garnered a lot of interest on the Innovation Days show floor. By combining the controlled vibration of the tool holder with tool rotation, the ultrasonic technology offers high accuracy on difficult-to-cut materials. The Ultrasonic 20 linear combines ultrasonic and HSK milling for machining a wide range of materials.

Related Content

Tolerancing in Mold Design, Overcoming Cutting Tool Vibration, SPE MTD Updates & More Most-Viewed May Content

Every month, MMT draws inspiration from its diverse readership's wide-ranging interests, from mold design tolerancing to cutting tools and beyond. Here are May’s top 10 most-viewed articles, based on Google Analytics.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)