The Designer’s Edge: Lifter Rods

Randy takes a look at round vs square shanks, decelerated lifter travel and part removal.

Round lifter rods are maintenance friendly when performing repairs. Typically, a nitrided ejector pin will be used because the center is soft to drill and tap. When using round lifter rods, it is critical to key the rod to prevent rotation and damage to the lifter and cavity.

Square lifter shanks can also be used, but their repair work is a little more involved. If a square lifter is bent or broken, you cut the shank where it is positioned in the bearing surface and splice a new shank with a notch. Then bolt and dowel it. Whether the lifter is hardened steel or alloy, you can use P-20 material and nitride it.

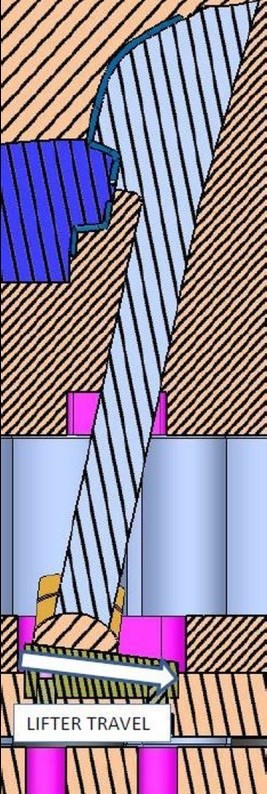

The lifter slide (in the ejector plates) should also move freely by hand with no dragging to reduce the chance of wear or failure. This is especially recommended when the lifter is decelerated or accelerated, as this adds more mechanical friction. This is used when the lifter detail or undercut in the part is on an angle and not parallel with the parting line, which means the lifter will need to travel more or less than the ejection to pull on the angle of the part detail. The lifter slide pocket will be machined on an angle, so as the ejection travels forward, the lifter will either be above the ejection with an accelerated slide or below with a decelerated slide. See image.

A lifter that has decelerated travel. When the ejection is all the way forward, the lifter will be lower than the rest of the ejection.

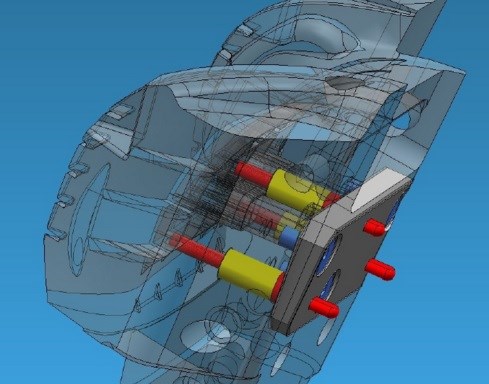

consideration to tool design involving lifters is how to hold the part in position without sticking to a lifter. A common method is to add ring detail on the ejector pins to hold the part in position. This prevents the part from traveling with or sticking to the lifter. Also, with some flexible materials such as PP, it is necessary to have an ejector pin or straight lifter bar going up the side wall of the part to prevent the part from flexing and sticking to the lifter. In a few cases push pins can be used on the lifter detail to assist with part release from the lifter See image.

A lifter that has push pins designed in to prevent the part from sticking to the lifter detail. The pins are in red and the yellow represent the springs.

.jpg;maxWidth=300;quality=90)