Getting Schooled in Mold Material

I met Roland Krevitt shortly after we launched MoldMaking Technology magazine back in 1998 and he had a wealth of experience and stories to share back then. He is still sharing them today. They are mostly about his experience with mold materials, which is always quite the hot topic with MMT's readers, so I thought I'd let him share some of his experiences here with you.

I met Roland Krevitt shortly after we launched MoldMaking Technology magazine back in 1998 and he had a wealth of experience and stories to share back then. He is still sharing them today. They are mostly about his experience with mold materials (specialized tool steels), which is always quite the hot topic with MMT's readers, so I thought I'd let him share some of his experiences here with you.

"To summarize my career so far, I have been to seven Asian countries a total of 90 times and Europe five times in my role as a tooling program manager for Apple, Plantronics and Redwood Engineering.

After obtaining my BSME from Berkeley and MBA from San Francisco State, I joined Hewlett Packard in 1971 as a manufacturing and tooling engineer. I managed various plastic injection and die casting programs for 12 years, but became restless in the huge corporate environment. When asked in 1983 to join Steve Jobs’ team at Apple, I jumped at the chance.

My first trip offshore (after only one week at Apple) was to meet with the engineering staff from Apple’s printer OEM at their factory in Japan (about an hour by bullet train Southwest of Tokyo).

After reviewing the part designs and the tooling plan, I asked what mold steel would be selected. The answer was NAK 55, a free machining age-hardened tool steel with nickel, aluminum, copper. Never heard of it! (I was to find out about NAK 80 later.)

At HP, we frequently used P-20 because the volumes were low. I was very familiar with P20, but wondered why these suppliers weren’t recommending P20. After all, didn’t everyone use it? I had a lot to learn. I decided that I needed to find out why this other material was becoming so popular throughout Asia, especially in Japan.

Faced with signing off on millions of dollars worth of tooling made with a steel I was unfamiliar with, I decided I had to educate myself. I set up a meeting with the moldmaker so I could hear firsthand why they preferred NAK 55. I also wanted to check out the shop.

Throughout my career, I always tried to visit the second or third-level suppliers, so that I would thoroughly understand the food chain and their challenges.

We jumped on a bullet train and traveled on down to Hamamatsu (about an hour away) to meet the Watanabe brothers, the owners of the Shin Nihon Kanagata. They were very friendly and hospitable, but since they did not speak English translation was critical. After a tour, tea, and lots of technical conversation, I had my answers. NAK 80 and NAK 55 had become the standard pre-hard tool steel for the higher quality molds because of its unique characteristics.

Shortly after my return to the U.S., a moldmaker in Southern California told me about new tool steel that he highly recommended for a mold he was going to build. He raved about it and told me it is harder than P20, machines great, and the best part was when you had to weld it.

The owner of this company did his own welding, so he knew what was involved. With this material, he was able to weld in a cavity, machine it, EDM it, polish it, have it textured, and never see any weld sink or evidence that any welding had been performed. Of course proper pre-heat is necessary, so is using the proper welding rod.

I’m sure we’ve all experienced companies that are adamant about no welding in a cavity, and that if a mistake was made, the cavity had to be thrown away and a new one built. With this new tool steel, that was not a problem.

As I was to learn, the key to successful welding is to properly pre-heat to between 600 and 750oF, and hold it in that range during welding. Then post-heat the steel to between 860 and 940oF. The great advantage of NAK is that you don’t have to formally heat-treat it. If done correctly the results are astounding. I was sold!

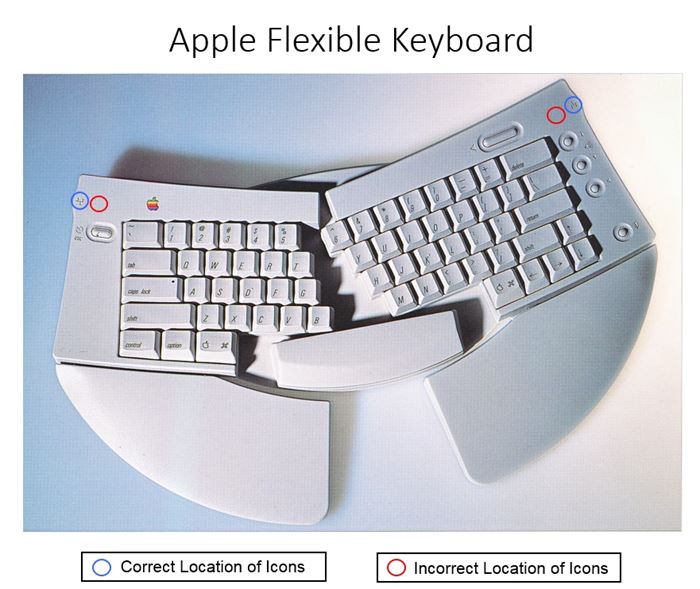

The next project was the development of a very unusual keyboard with a very different design concept. It swiveled, so that it could be adjusted to a comfortable angle to avoid repetitive stress injury (RSI). We called it the Flexible Keyboard.

The moldmaker of choice was in Southern California and was well known for high quality moldmaking. At our first meeting, he informed me that they had standardized on Stavax for cavities and S7 for slides and inserts and that’s what they wanted to use for this keyboard. I had to drag him kicking and screaming to the world of NAK 55. But, since I was the customer, he agreed to use it. He advised me that any problems caused by the steel would be my responsibility. I found that a moldmaker will use whatever steel you want as long as you assume full responsibility.

The cavity had several icons on the very visible top surface that were down in the part, and therefore they were up in the steel. I call them “upstickers.” The icon shape was EDM’d into the upstickers, carefully polished and then sent out for texturing.

The moldmaker made a mistake in the location of some of the icons as shown in Figure 1. He had to weld on new upstickers onto the cavity surface, in the correct location, re-cut everything, polish the icons and the main surface and then have the cavity textured. Fortunately, he caught the mistake before texturing. It is sometimes unsettling when sending a cavity out for texturing with a lot of welding. Like a box of chocolates, you never know what you will get. With most grades of mold steel and this amount of welding in the cavity, you may as well scrap the cavity and start over. When our texture came out perfect, he was extremely relieved and thanked me for specifying NAK.

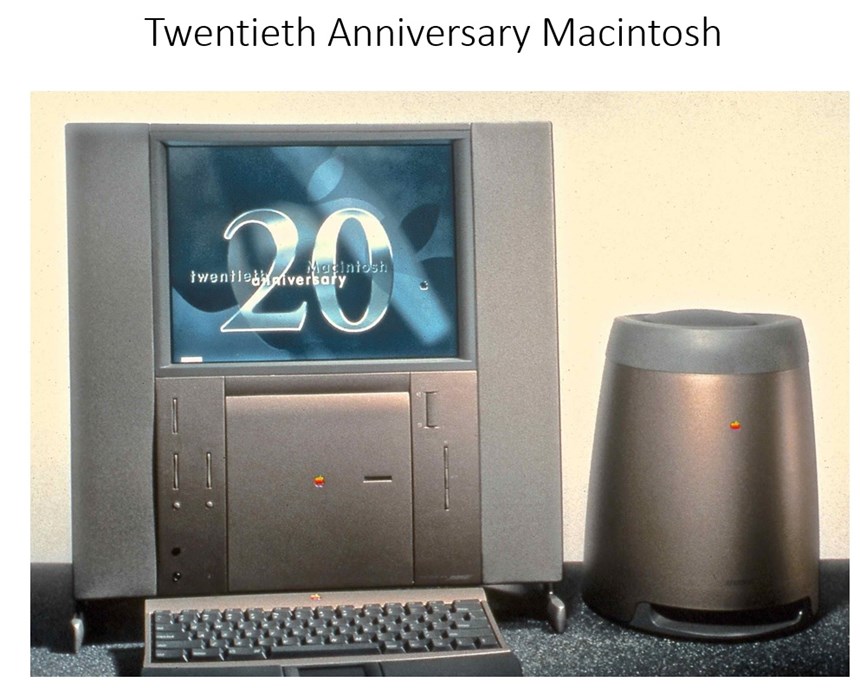

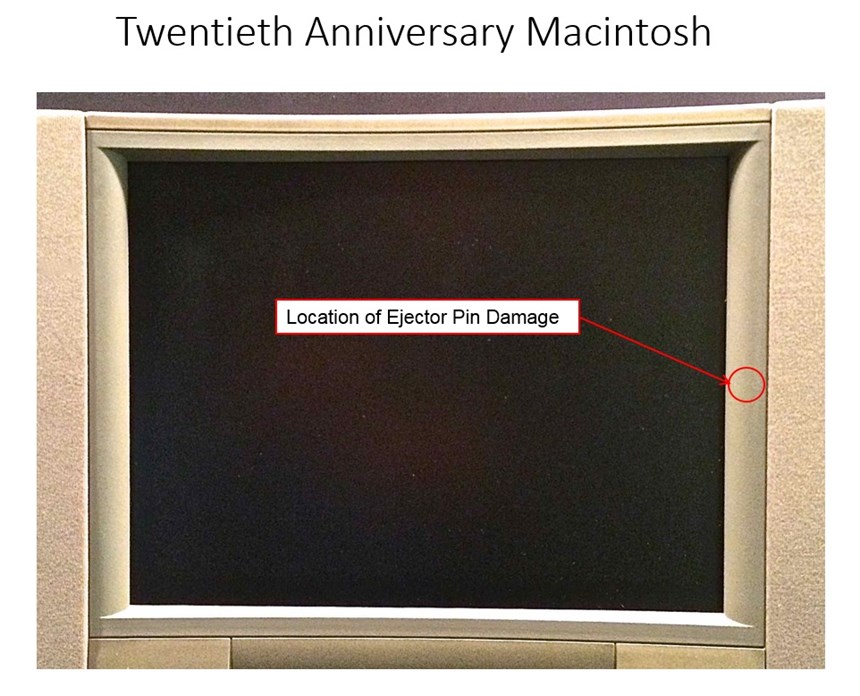

In 1995 Apple decided that we should build an experimental computer that, as it turned out, was the forerunner for the iMac. It was kind of a limited edition, expensive market research product and was called the Twentieth Anniversary Macintosh. It was released on the 20th anniversary of the formal start of Apple Computer (see Figure 2).

There were 40 injection molds and 20 sheet-metal dies. The contract manufacturer was in Westford, Massachusetts, the molder was in Arlington, Vermont, and the major moldmaker was in Charlotte, North Carolina. The contract manufacturer sub-contracted molds for the smaller parts to four other moldmakers in Arlington, Vermont, Horse Shoe, North Carolina, Erie, Pennsylvania, and Hoosick Falls, NY. This was a perfect application for NAK 80 and I had to make arrangements to get it to all of these guys.

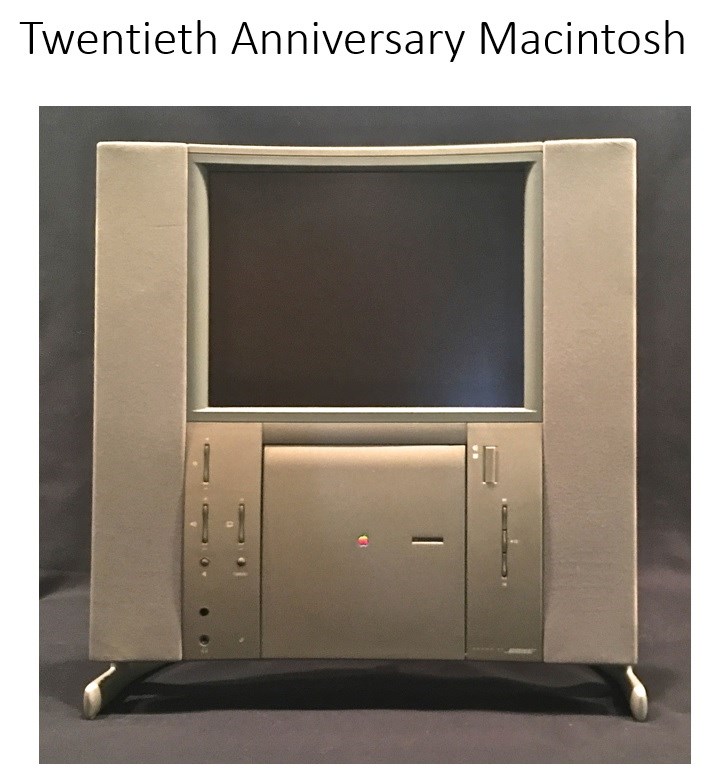

As you can see, there is a lot going on with this product as far as controls. The industrial design guys crammed as much into this product as they could as you can see in Figure 3. When the product was designed, we had a glass cover to protect the display. The mold was built. Then engineering and industrial design decided that the glass cover was not needed after all, so we redesigned this area. However, this meant we had to change the mold, which required a lot of welding.

During a conversation with the mold shop engineering manager, he revealed that he was glad they bought a bunch of NAK 80 welding rod. I had told him upfront that we might be making some changes, since this was an experimental product, so he was prepared.

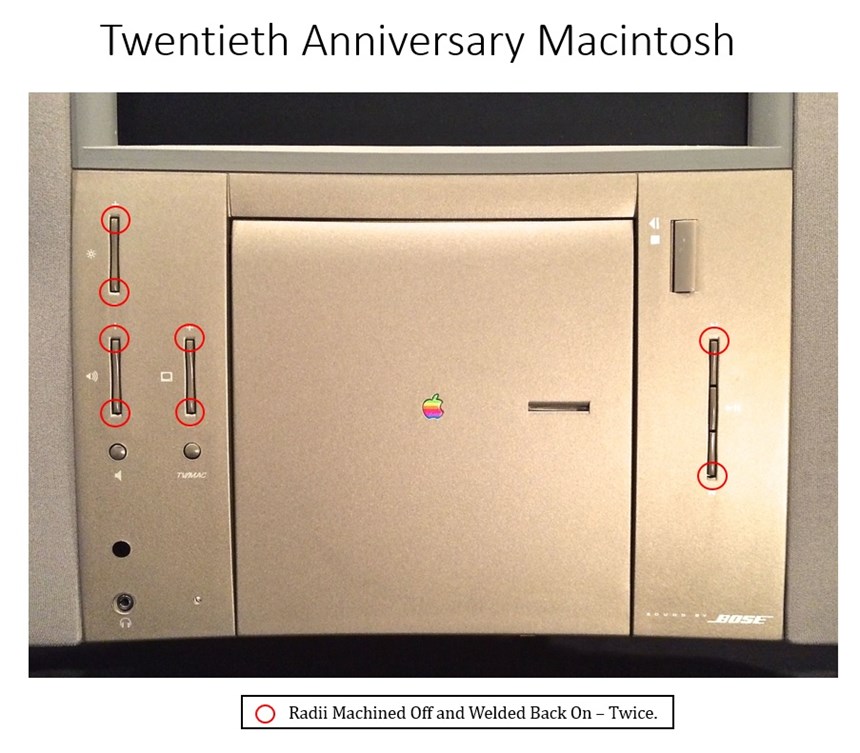

Notice that the entrance to the button openings curve in. Industrial design didn’t want just a sharp rectangular opening. These were formed by a radius in the corner of the blade that came from the cavity side and shut off on the core. It seems that one of the moldmakers thought they had made a mistake by leaving these radius features sticking up on the steel so he machined them off (see Figure 4).

They caught the mistake and welded the radii back on, EDM’d and polished again. Then a few days later, someone else made the same assumption and machined them off again. Once more, they were welded on, burned and polished. After welding and polishing twice, there was no evidence of any welding. And this was welding on top of welding! All the molds were tried out and we went into production.

A week or two after startup, I got a call from the project manager at Mack Molding. It seems that after they ran a few hundred main housings up in Arlington, Vermont, an ejector pin seized when the ejector plate was pulling back. The pin broke and no one noticed that there was about an inch of it sticking out. The mold closed and that pin was impaled in the cavity right (see the red circle in Figure 5).

The mold was sent from Vermont back down to Charlotte for repairs. Remember, they had a lot of NAK 80 welding rod on hand. This is the area where the display "window" was modified by welding when we eliminated the glass cover. Again, welding on top of weldling. In this case, we thought it best to polish out all the texture since this was in the most visible area of the product and then retexture the whole bezel at one time. They welded, polished and sent the cavity back down to Mold-Tech in Atlanta where it was textured in the first place. I flew down to Atlanta to approve the texture pattern before it was sent back to Charlotte for reassembly. It looked great and the texture measurements were right on.

After leaving Apple in 1997, I spent 10 years with Plantronics, a headset manufacturer, and again specified NAK for many molds. Over the years I learned about the differences between NAK 55 and NAK 80. In fact, in Asia, several OEM companies wanted to use NAK 80 for prototype or short-run molds (soft tooling). They all recognized the advantages of using NAK for many different applications, especially if numerous design changes are anticipated where welding will have to be employed.

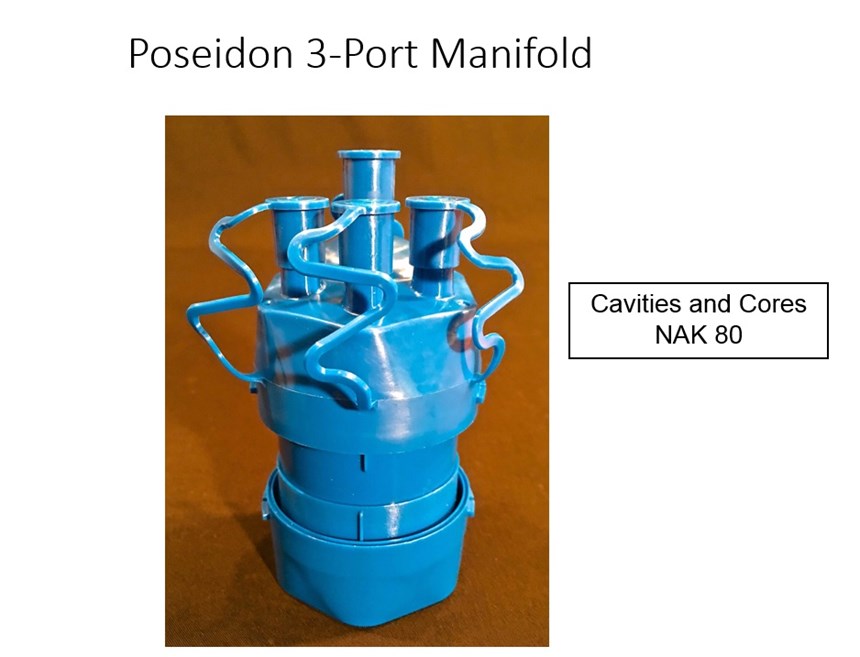

I now have my own consulting business, Redwood Engineering. For the past year I have been working with a small tooling and molding company, Micro Precision Technology, in the Dongguan area of China. They are producing a medical product that is used in arthroscopic surgery. As you can see from Figure 6, the surfaces are highly polished. So this dictated that the cavities were made of NAK 80.

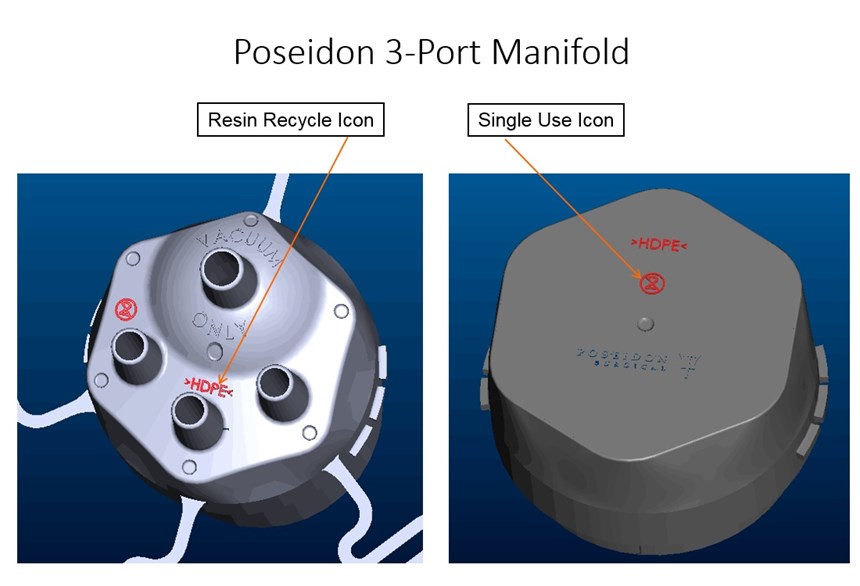

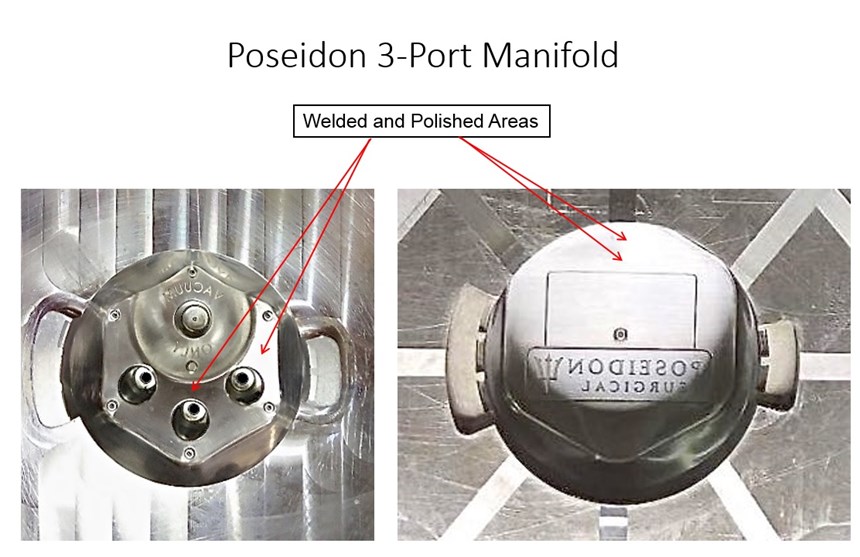

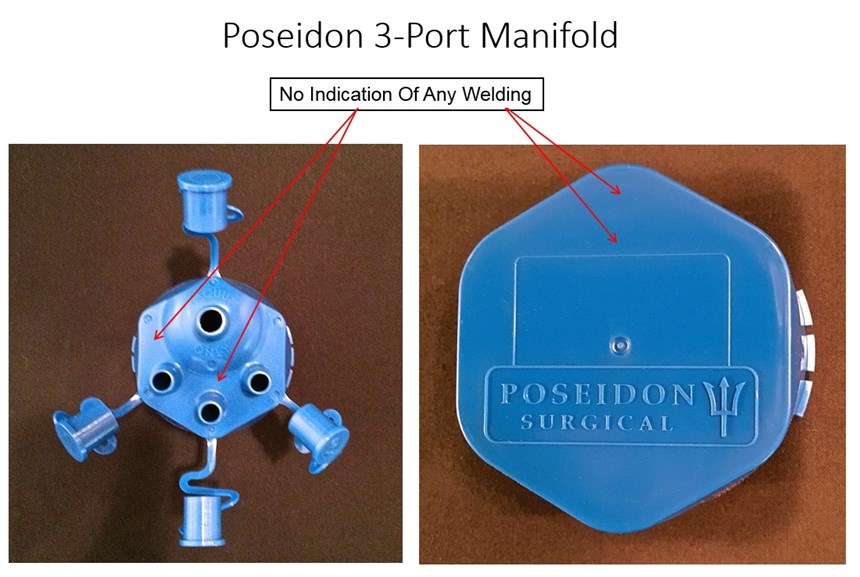

We designed the resin recycle symbol and the single use icon into the two parts as shown in Figure 7. After the molds were built, we decided we did not want those two sets of icons on the parts after all. Not to worry, the cavities were NAK. So, I told my contact at MPT to have all that nomenclature removed. I didn’t tell her how to do it and left it up to them to decide. I knew they would not make the cavities over again, so I just waited. A few weeks later I visited MPT and was shown the molds and parts. They welded up the depressions in the cavities, machined and polished the surfaces. Figure 8 shows the cavities. We couldn’t see any evidence of welding. The parts are perfect (Figure 9).

After many years managing numerous tooling programs for a lot of different products, I still get a kick out of showing people what this steel can do to improve their molds and make them look like heroes!"

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More