Attract New Customers with Full Product Development Solutions

One mold builder dramatically increased its ability to move fast and help customers get product to market in the shortest amount of time by applying its mold leadtime reduction principles to its product development processes.

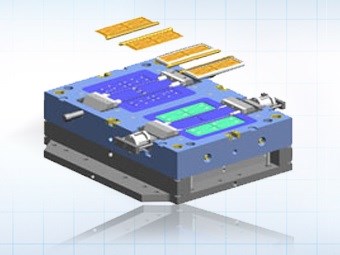

MME group was founded in 1974 as a tool and die shop in St. Paul, Minn. Twenty years later, and before taking on production molding, the company discovered that short leadtimes for new tooling was a key component of the entire new product development process. The company became a leading tool shops in the Midwest by reducing the typical industry tool construction leadtime from 12 weeks to an average of four. They then applied those same principles for reducing mold building leadtimes to product development, which has helped them get their customers' products to commercialization fast.

Related Content

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.