Ultra Tool Group: Multiple Mold Specialties Garner Profits Galore

Designing a number of molds along with effective strategic planning rakes in business - and an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

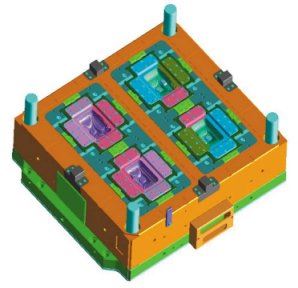

Ultra Tool Group (Grantsburg, WI) - a producer of high-volume production, multi-shot, MIM and Thixotropic molds in the consumer disposables, consumer electronics and medical industries - has spent the last 24 years perfecting its craft and gaining a reputation for building high-quality, high-complexity tData Import Utility : Edit Contentooling by focusing on leadtime reduction and adopting manufacturing philosophies such as Theory of Constraints (TOC) and lean manufacturing.

With leadtimes of as little as four weeks, this 70-employee moldmaker has recently started focusing its efforts on ways to reduce molding cycle times through tooling innovation for both single- and multi-shot tooling. "Because our corporate culture is so speed driven, we have moved into our next phase involving the development of tooling that can run some of the fastest cycles in the world," Wayne Shakal, Ultra Tool's business development manager, notes.

During the past several years, Ultra Tool has discovered that concurrent tool building requires very rigid control of information and documentation. "Along with ISO 9001 certification, we have developed a paperless system that ensures that any component that can be retrieved from the CAD stations of the plant floor is a build-to file and ready for manufacturing," Shakal states. "Our paper-less system includes custom-built software that gives tooling experts on the floor Internet access to all pertinent data applying to any given job. Our personnel out in the field also have access to this information. This makes it possible to obtain information directly from our network while at a customer's facility."

Maintaining Leadtimes

Ultra Tool was founded in 1978 by Thomas Finn and sold to Patrick Finn in 1994. Up until around 1994, the company had 13 employees - but then business exploded. "Growing from 13 to 60 employees in about a five-year timeframe taught us the importance of standardization and the need for dedication to standard operating procedures," Shakal says. "Without putting proper data and job management systems in place, we would have not been able to handle the growth we were experiencing and at the same time hit the delivery and quality demands of our customers."

The next step was developing a system to hit accelerated deliveries without corrections needed to the tooling after the first sampling. "There are very few moldmakers that can consistently deliver Class 101 high-volume production tooling in four- to five-week leadtimes," Shakal notes. "There are even fewer that can deliver the mold this fast and produce good quality first shots. We have seen no other mold manufacturing system that we feel works as well as ours to consistently maintain accelerated deliveries and keep the projects on time. This is one of the main reasons we grew five-fold from 1994 to 2000."

It was around this time that the company first seized the opportunity to supply tooling at greatly reduced leadtimes, according to Shakal. "From what we've observed, the plastics industry in the past has allowed for longer deliveries on higher cavitation and multi-shot tooling," he comments. "Consequently, many of the moldmakers in this market have failed to develop systems and procedures that afford them the ability to drastically reduce leadtimes without sacrificing quality and customer satisfaction. This is especially true for Class 101 tooling with 2,000- to 3,000-hour build times and above. We've seen this as an opportunity to market our abilities in an arena with very few competitors that can offer the deliveries that we can.

"We utilize various techniques in order to compress the deliveries of molds," Shakal continues. "The first step is the implementation of a planning group whose sole responsibility is to establish product timelines. Individual components are evaluated for their specific impact on production capacity and their effect on delivery. Once potential bottlenecks and the critical path for the tool build have been established, a components schedule is developed."

Through a hand-off meeting, tool programs are then released from engineering to production. Designs are developed in 100 percent solids. Build-to files for individual components are then released to production for programming and component manufacturing. "We also apply TOC and lean manufacturing principles to the whole process," Shakal states. "This upfront analysis allows for special attention to be applied to critical path components. In order to effectively hit accelerated deliveries on a daily basis, concurrent tool building of these critical path components is implemented.

"Another factor that is somewhat intangible but is important in successfully meeting aggressive leadtimes is that we have a company culture that is geared toward speed," he continues. "This passion for speed often extends into many of the hobbies of various Ultra personnel - some of whom are involved in drag racing, stock car racing, snowmobile racing and, believe it or not, lawnmower racing."

Equipped for Speed

According to Shakal, Ultra Tool runs new, high-end equipment similar to its major competitors. "It is the techniques that we are using to increase the actual throughput of this equipment that make the difference," he states. "When going through our facility, you would see a very 'compact' layout that is about half of the actual floor space of other moldmakers' shops who are building the same types of tooling with similar sales volumes."

Currently the company utilizes 26 seats of Unigraphics software for both design and programming. "By combining Unigraphics Moldwizard with internally developed customization of UG, we are constantly pushing the design automation envelope," Shakal notes. "Manufacturing has utilized offline programming on all of the equipment, including sinker EDM. We also utilize pallet changeover techniques on our CNC and EDM departments and a 360-position 3R Workmaster robot for sinker EDM."

Shakal points out that Ultra Tool also has realized the benefits of an internal IT staff that is "constantly working on programs to increase the level of automation beyond what is currently available by equipment and software suppliers" - including programs involving quoting efficiency and accuracy all the way to the final tool build. "An example of this is software that we've developed for data collection on the shop floor," Shakal elaborates. "This allows us to collect real-time data such as labor and machine utilization, which helps us quickly make the difficult scheduling decisions associated with a job shop environment."

Additionally, the company is always striving to find methods - whether through automation or improved procedures - to increase its throughput per employee. Robotics, customization in UG, web pages on the floor and pallet changers on CNC are just some examples of this.

"What makes our company unique from a moldmaking standpoint is an unwavering commitment to speed and delivery," Shakal affirms. "We accomplish this by having a willingness to adopt manufacturing techniques that may be common in other manufacturing environments but unusual in moldmaking. We have found that by treating moldmaking as a manufacturing process as opposed to a 'one-off' craft trade, it becomes easier to identify areas that are having a negative impact on throughput. Another area that we feel very strongly about is our intensity. Speed is so entrenched into our culture that it can be described as a true burning desire to continually find new ways of manufacturing tools faster and developing tools that will run faster when they get in the press."

Telling the Truth

In the late 90s, Shakal recalls all of the talk in the industry that Asia was "so much faster" than the United States. "We have found that this is not the case," he notes. "Although tooling can be built fast globally, we've seen that it is very easy for programs to start dragging out longer than expected after first shots. We feel that it is important for our customers and prospective customers to track true costs and analyze all phases of a program. What we - along with many of our customers - have found is that when analyzed, there is little if any savings in many of the tooling programs that are now being placed overseas."

Ultra Tool plans to continue educating its customers on what it deems "true" costs. "We have been amazed to find so many corporations that do not have a good feel for what tooling is really costing when all of the true variables are evaluated," Shakal says. "It is too easy to see lower tooling prices and believe that the savings are real. The availability of this data is limited; consequently, we feel it is our responsibility to continue to gather data and educate.

"We were recently awarded a program where our main competition was a Korean moldmaking source," Shakal continues. "The sale was won by presenting their probable time to market using Ultra verses using their Asian source. Even though the Korean source also was offering an aggressive delivery, the customer came to the realization through past experience that their chance for immediate success with the tooling would be limited. The first major project that our industrial engineer is doing is gathering real data that will show the true cost of doing business with reputable U.S. moldmakers versus foreign competition. We feel that this would be an excellent study for graduate work in an international business program. If we can successfully get this going, we believe companies will be more apt to share accurate data for educational purposes."

Expecting Excellence

Behind every mold built speedily is an efficient team of program managers, mold designers and production staff that work in sync to get the job done. "We are always looking for people that have ability and potential, but more importantly have a strong desire to succeed," Shakal says. "By offering in-house apprenticeship training, tuition reimbursement and by putting promising candidates through school, we have been able to maintain the level of expertise required for the high-end tooling markets.

"We seek the best people in their fields, pay them above the industry averages, and give them a fast-paced, goal-driven work environment," he continues. "Admittedly, our intense work environment is not right for many engineers and toolmakers. However, we've found that when we do personality profiles on potential employees, we have extremely low turnover on those persons. When we deviate from this philosophy we can run into problems."

This is one of the reasons that Ultra Tool plans to add a human resource manager in 2003 whose main job will be to recruit new talent. "We are always advertising for true journeyman toolmakers and engineers," Shakal explains. "By continuously advertising, even when capacity doesn't necessarily require another toolmaker, it allows us to search for the top five percent in talent. We've found these people to be very difficult to find and that it takes a lot of dedication on our part to find them."

To keep its employees on track with constantly changing technology, the company holds a bi-weekly group meeting targeting specific areas of interest. "One major training program we are doing at the moment is design automation," Shakal says. "We also offer business training for people that have been chosen for leadership positions." Additionally, Ultra Tool offers tuition reimbursement for continued education.

Forging Ahead

Ultra Tool will continue to fine-tune its multi-shot technologies - something that it has already focused on substantially. "We've found this to be another area where there are fewer competitors that can get it right the first time out of the chute," Shakal says. "Our plan is to continue utilizing our R&D group in the development of new tooling technologies that will offer the best ROI possible for our customers. As our various patent-applied-for technologies become available, we will continue to increase market share on high-volume and multi-shot production tooling and at the same time have the capability to build the tooling faster than anyone that we know of at this time. This means a lot to our customers who are constantly under pressure to get to market early.

"Although we believe we have one of the most efficient moldmaking systems in the world, we also believe that there are infinite opportunities to improve the efficiency and profitability of the moldmaking process," Shakal continues. "We feel that because the moldmaking industry originated as a highly skilled craft-trade, very little thought ever went in to efficiency. Through the years, high volume manufacturers and service companies alike have realized the benefits of taking a very scientific and proven approach to systems and methods improvement. We are unaware of any other moldmaking operation that has an industrial engineer on staff whose sole responsibility is to find and develop new methods to increase moldmaking efficiency."

Shakal adds that additional R&D and new tooling techniques will allow Ultra Tool to continue to develop new types of tooling that have never been done before. "Innovation is still the strength that U.S. manufacturers have over most foreign competition," he states. "We see this ongoing global competition as an opportunity or catalyst to force us to innovate both new tooling technologies and new tool building techniques."

Ultra Tool maintains an "aggressive" growth plan and expects to continue to grow at a rate in excess of 20 percent a year, through innovation in both tool manufacturing and new tooling technologies, Shakal concludes. "On the tool manufacturing side, this will allow us to build tools faster and at the same time be highly cost competitive. On the new tooling technologies side, we will continue to offer new manufacturing solutions for high-volume molding applications that allow our customers to be highly competitive in production."

Related Content

FAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreU.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreAMBA Calls Members for Comment Submission During Tariff Review

The imposing of a 25% tariff of molds, tooling and dies imported from China is under review by the U.S. government.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More