Triangle Tool: Product-to-Tool Service

This Large Shop Leadtime Leader Winner penetrates new markets with complete product-to-tool service while investing in technology.

Triangle Tool Corp. (Milwaukee, WI)—specializing in injection, SMC (sheet molded compound) and BMC (bulk molded compound) compression, structural foam, and blow molds for large plastic parts in addition to specialty large part machining—has realized that the best way to survive the current economic climate is to constantly reinvent itself by continuing to invest in technology and equipment while penetrating new markets.

Mold Manufacturing at its Best

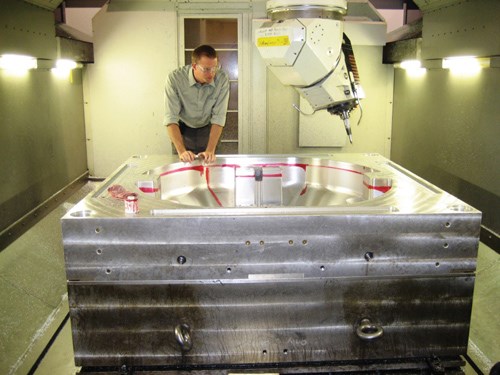

Triangle Tool is best known for its large part, highly engineered molds. The company defines its “sweet spot” as 1000 tons to unlimited size. “Large molds are not for every shop,” Baez notes. “There are challenges at every stage of large mold development and size greatly multiplies cost if these challenges aren’t addressed upfront. We have the experience to navigate past these challenges. Our customers know this and recognize the value of a Triangle Tool mold.” Baez is quick to point out the true value of a mold is not the price of the mold. “For savvy decision-makers and purchasers, a mold’s price is not measured strictly by the price paid,” he states. “It is measured by mold price, troubleshooting, repair, maintenance and all other ‘buckets’ throughout the life of the mold. Those purchasers that use one metric (price) represent companies that are likely to struggle in the long-term. It raises a red flag when they view the tool as a one-time cost because incidentals drain resources and add cost over the long run.”

Leadtime Tactics

Baez notes the company’s average build leadtime on a project is 11 weeks, maintained through “concise scheduling utilizing both computer and visual boards. They are reviewed twice per shift by our shop managers. The board gives us a fish bowl view of our machines, our people, and the status of each job. We know where each core and cavity is for a particular job, we know who is going to be working on them next and we can adjust accordingly.” As owner Roy Luther states, “My wife should be able to come in here and determine exactly where a customer’s job is at any given time.” This strategy has helped Triangle Tool meet its on-time delivery “without failure or excuse,” Baez adds. “When delivery is critical, knowing your customer’s drop dead date is paramount. We will hit the drop dead date, but in addition, our flexible scheduling will allow us to take advantage of any holes and expedite the delivery.”

A large mold project can bog down many shops. Triangle Tool has the capacity to manufacture multiple large mold programs concurrently. With more than 170,000 square feet and more than 45 CNCs, Triangle Tool is able to handle these large tooling programs at any given time. “Our capacity gives us an advantage when procuring large molding programs,” Baez states, “In manufacturing, if you can’t avoid bottlenecks, you can’t better leadtimes. We have the men and machines to handle multi-mold programs from different companies and expedite as needed.”

Another strategy that has paid off is having Triangle’s engineering team meet with OEM product designers and engineers prior to tool launch. “Design for Manufacture (DFM) has allowed our customers to reduce their design and engineering hours,” Baez says. “In certain cases, companies have been able to develop parts that require more engineering for the tooling, but eliminate costly assemblies. Whenever you can eliminate assemblies, the benefit becomes very tangible to those in charge.”

Marketing Strategies

Triangle Tool’s forward thinking is evidenced by the number of strategies it employs not only when dealing with local competition, but also in its global growth. Currently Triangle Tool’s sales team is focused on untapped, emerging markets. “We have hired three new salespeople specific to new business development,” Baez notes. For years, Triangle Tool built molds specifically for the North American market. During this time, several relationships were formed with European companies with U.S. operations. Triangle Tool has earned their respect and is now looking to expand directly into the central European markets. “We’ve had these relationships for years, but we didn’t have the structure in place to aggressively pursue this focus,” Baez elaborates. “With the margin increasing between the Euro and the dollar, we are now a viable option. Because of our leadtime capabilities, we can manufacture, qualify and ship a mold within the same window of many European tool shops.”

In addition to maximizing current relationships, Triangle Tool will be exhibiting at the international plastics show K-2010 in October of this year. “The importance of K cannot be understated,” Baez notes. “We are committed to becoming a supplier to the central European markets and this is our next step.” Baez adds that Triangle Tool is working with state and federal agencies to help in the development of global business opportunities.

“Targeting countries in this area allows us to immediately provide a highly engineered product at a cost tied to the value of the U.S. dollar,” Baez explains. “In these countries, we are targeting industrial, material handling and heavy automotive. Companies within these countries need proven solutions for their molds. They understand that once that mold is in their facility, it has to be right and it has to last.”

Equipped for Efficiency

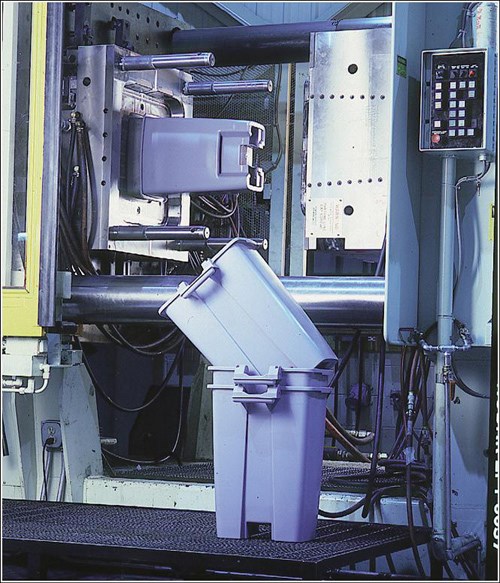

It is vital that Triangle Tool’s investment in equipment and technology support the company’s marketing endeavors. For example, the company’s recent purchase of a high-speed, 1100-ton Husky HyElectric molding press is for sampling molds made for high-volume production. These molds are generally thin-walled and require fast cycles in order to be competitive in their markets.

Triangle Tool also added to its machining capability in a large way. So big, in fact, that the company needed an additional 18,000 square feet to house MECOF’s “The Machine.” (mecofspa.com) “With the work we are doing for the transportation and energy industries, we needed to expand our five-axis capabilities beyond our competitors’ scope,” Baez comments. This bridge style machine has a table size of 374” x 197” x 79” (xyz). “We could always build the biggest molds for the industry,” he emphasizes. “Now, we build them faster.”

Investing in the latest technology and equipment also is necessary to meeting customer demands. Triangle Tool has continued to add to its facility and the equipment used to manufacture. “Our continual upgrading of our five-axis capability has been a real benefit to us and our customers,” Baez says. “Because five-axis milling increases versatility, we are able to cut more core and cavity details and reduce EDM time. Anytime you can avoid pulling an electrode, programming an electrode, cutting an electrode, checking an electrode, and finally EDM’ing, you are able to reduce leadtimes and costs for the end user.”

The company also has added new automation equipment in the form of two new OKK HM1250S shuttle-styled CNC machines (okkcorp.com)—which allow the operator to safely set up one piece for machining, while the machine is milling on a separate piece.

A Powerful Workforce

“People are Triangle Tool’s biggest asset,” Baez states. Triangle Tool mixes younger employees with seasoned tradesman, which breeds creativity. “Learning doesn’t just flow down. Our younger employees are bright and have the computer skills necessary for 21st century manufacturing. Our veteran employees bring time-tested techniques and an understanding that those techniques may be changing because of technology.”

Baez notes that as technology has advanced, so has the level of communication between these two groups.

Education: Education and training is ongoing at Triangle Tool to help the employees stay ahead of the technical changes in the industry. “Engineering software for design and programming is a critical focus so that we can keep up with the capabilities of the new equipment,” Baez explains. “Growth discussion focuses on efficiently managing our new customers. Currently our sales engineering team cultivates new prospects, secures new business and helps manage projects until they are completed. This is in large part because our salespeople come from technical backgrounds, specifically toolmakers and designers, which allow them to be the primary interface with the customer.”

Triangle Tool understands that future growth will be limited or sustained by being able to find skilled employees. It is Triangle’s prerogative to be proactive and “grow” its own employees through the state of Wisconsin’s apprenticeship program. “Since Wisconsin is one of the few states with a fully accredited indentured apprentice program (Tool & Die or Machinist), we work directly with local technical colleges to develop the programs that meet industry needs,” Baez points out. “Since the 1960s, Triangle Tool has offered a state-approved apprenticeship program. It entails a 10,400-hour commitment between the employer and employee.”

Employee Perks: The owner of Triangle Tool, Roy Luther, has made a point to provide employees with on-going training opportunities, high paying positions, fully paid health insurance, and rewards for their dedication and service, Baez maintains. “Employees at Triangle Tool are some of the industry’s highest paid and the success Triangle Tool has achieved is—in large part—due to the symbiotic relationship between management and employees,” he notes. “Our health benefits are the envy of the industry. As many Wisconsin employers are reducing benefits, Triangle Tool continues its self-funded plan that covers employee’s health needs. One giant advantage of Triangle Tool’s healthcare plan is there are no premiums taken from their weekly paychecks.

“We have two yearly traditions for employees at Triangle Tool: the Christmas Party and the Golf Outing,” Baez notes. The Christmas Party is attended by all employees and their spouses and has greatly added to the family atmosphere at Triangle Tool. During this event, employees are recognized for their length of service. An employee will receive a gold ring at five years. For each additional five years of service, the employee’s ring gets four diamonds added per period. At 25 years, the finishing gems—four rubies—are added to the corners of the ring.”

Furthermore, to show his appreciation to employee dedication, at 20 years of service, Luther provides two additional weeks of vacation (seven weeks total) for an all-expense paid vacation anywhere in the world the employee and their spouse would want to travel.

Forging a Path

Baez is confident that Luther will continue to lead Triangle Tool on a path of success. “Mr. Luther’s goal is simple,” Baez notes. “He wants to make his customers successful. In order to achieve this, he gives his team the latest equipment and the employees work hard to maximize his investment. Growth is every company’s goal, but not every company is willing to do what it takes to achieve it.”

Triangle Tool clearly is not slowing down. “We are evaluating the purchase of a large (4000 ton) SMC sample press so that we can continue to enhance service for existing customers and develop new customers in specialty large machining market,” Baez notes. “In a time of recession, it was a well-planned business decision to move forward with a $6MM expansion to attract new business. We have chosen to forge a path to lead the industry, which requires focus, commitment, and investment in employees and technology.”

Related Content

2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMMT Chats: The Family of Business – From the Farm and into the Future

MoldMaking Technology Editorial Director Christina Fuges interviews the Eberle brothers of 2024 Leadtime Leader Award Winner Dynamic Tool Corp. about their moldmaking journey and the family dynamic of the business.

Read MoreLeadtime Leader Award Honors the Many Faces of Moldmaking

This Award is not only for big mold shops! Check out the criteria for entering our 2024 competition.

Read MoreMMT's Most-Viewed March Content: Digitalization in Tooling, The Leadtime Leader Awards & More

March was a big month for MoldMaking Technology. Not only did we celebrate our 25th Anniversary, PTXPO, and announced the return of the Leadtime Leader award, we also continued to cover some of your favorite topics. Take a look at what you might have missed in March.

Read MoreRead Next

Reaching Out to a Different Market to Survive Tough Times

This mold manufacturer has reassessed its market base and began dabbling in the energy industry based on its experience with CNC machining—making it a natural transition.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More