The Dielectric Decision: Water or Oil

The emergence of today’s technologically advanced oil-based wire EDMs is an opportunity for the average U.S. mold builder to set himself apart from the competition.

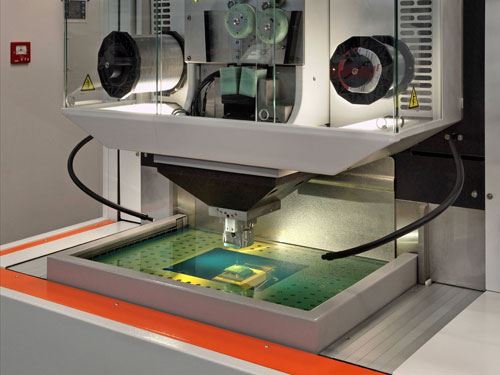

Water as a dielectric in wire EDMs has always been the standard, but the upsurge in micromachining has spurred the use of oil as a dielectric fluid instead. Unfortunately, not many U.S. shops are taking advantage of this technology. Shops that can benefit the most from oil-based wire EDMing include those working with carbide parts, those micromachining parts for nano applications and mold manufacturers.

Moldmaking: For the moldmaking and tool and die industries, oil-based wire EDMing allows shops to machine additional features into finished mold components without affecting their polished surfaces, unlike with water-based wire EDMing. These additional mold features often include lifter pins and other small details that must be done after a mold is completed.

In addition, moldmakers cutting fine mesh-type mold materials can oil EDM them without having such parts absorb water during the machining process or if parts are left on the machine for extended periods of time, as is the case with water-based wire EDMing.

Moldmakers use fine-mesh materials mostly for mold inserts to allow air to quickly exit mold cavities, which contributes to shorter injection molding cycle times. The material is also used in the medical industry.

Carbide cutting: Oil-based wire EDM is also advantageous for shops cutting carbide parts and facing similar water-absorption issues as shops cutting fine-mesh materials do. Water-based EDMing has adverse surface conditions caused by the water in the dielectric tank, so carbide parts must be dried as soon as the part is completed to prevent corrosion. An oil-filled dielectric tank eliminates these problems.

When carbide parts are left in dielectric water, the amount of water the parts absorb depends on the density level of the particular type of carbide. Once water is absorbed, corrosion can occur deep inside certain carbide types. This corrosion permeates way beyond an EDMed or ground part surface and is undetectable with simple visual inspection. As this corrosion grows, it jeopardizes the integrity of the finished part.

Micromachining: For shops micromachining parts for nano applications, oil-based EDMing allows them to successfully generate precise and clean part surfaces. This is critical when secondary cleaning or polishing operations are not an option on parts that are too small to handle.

Oil-based wire EDMs have been around for a while, but didn’t readily catch on because their cutting speeds were a bit slower than those of water-based wire EDMs. However, shops that weren’t so concerned about cutting speeds would use oil-based machines instead of water-based ones to eliminate the problem of corrosion buildup on parts left in machines overnight or for long periods of time.

In general, water-based wire EDMs have always delivered better cutting performance using small (< 0.004”) wire diameter because the water cools the spark gap much faster, allowing machine users to apply higher cutting currents to increase cutting speeds.

However, now some oil-based wire EDMs can cut at the same speeds as water-based machines. This is the result of advancements in EDM generator technology, such as the high-performance generator a new oil-based wire EDM for micromachining. Besides this special generator, other proprietary machine advancements to boost cutting speeds are incorporated.

Another challenge EDM builders faced with oil-based machines for micromachining was adapting automatic wire-threading capabilities. On water-based wire EDMs for micromachining, automatically threading extremely small wire diameters is easily achieved, but trying to automatically thread them through oil’s thicker viscosity took some new technology.

For example, a new oil-based wire EDM equipped with the only dual wire system can use wire that is 0.0008 in. in diameter, and it includes an automatic wire threader specifically designed for it. This threader allows that size wire to pierce the oil’s surface. The system has proven to provide consistently reliable automatic wire-threading cycles.

Cost Comparison

When comparing the operating costs of a water-based wire EDM to those of an oil-based machine, operating costs of the oil-based machine may be a bit higher in the first year of operation. However, in the years following, those costs are measurably less than with a water-based machine.

In the first year of operation, oil-based EDMs involve initial cost outlays for dielectric tank oil, and as recommended by most EDM builders, fire extinguishing systems—such as those used on die sinking EDMs.

What makes oil-based wire EDMs less expensive to operate after the initial year of operation is the fact that they eliminate the need for deionization resin bottles because oil does not break down like dielectric water does. Frequently changing deionization resins can be costly, especially true for shops that must maintain low water conductivity levels essential to achieving superior surface finishes. Keeping conductivity levels low (5µS) requires frequent resin changes.

Similar to water-based wire EDMs, oil-based wire EDMs also require filtering of dielectric fluid. Oil-based machine filters are the same as those used on die sinking EDMs. But, the wire EDM filters typically last longer than die sinker filters due to the fact that the micromachining wire EDM process generates fewer particles and material removal rates are lower.

Summary

As part sizes shrink to meet new and existing industry requirements, the use of oil-based wire EDMs for micromachining will continue to spread. It is widely known that the machines have quickly caught on in Asia and Europe. Many EDM builders believe that the emergence of today’s technologically advanced oil-based wire EDMs is an opportunity for the average U.S. mold builder to set himself apart from the competition.

Related Content

Flowmeter Enables Accurate Water Volume Measurement, Regulation

Hasco’s flowmeter, which can be installed anywhere in the direction of flow, aids moldmakers in rapid and easy flow rate readings on injection molds.

Read MoreU.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreVIDEO:"The Smith Boys" on How Moldmaking is an Innovation Machine

"The Smith Boys" AKA President of DME Peter Smith and Director of Sales, Scott Smith discuss why the moldmaking industry is an innovation machine and how it is crucial to remedying global supply chain issues.

Read MoreExploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MoreRead Next

Achieve More with Twin Wire EDM Technology

As wire costs continue to increase, twin wire will be recognized as a strong tool for fine tuning wire EDM performance and reducing cost.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)