Peterboro Tool: Niche Moldmaking Produces Profits

Producing wax injection molds has kept this moldmaker in the black for more than 30 years - and has earned it an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Specialization is the name of the game for Peterboro Tool Co., Inc. (West Peterborough, NH), a builder of wax injection molds for investment castings in the aerospace, commercial and firearm industries. Focusing on a specific type of mold has allowed this moldmaker to achieve more than $1 million in sales last year with just 12 employees and an average leadtime of three to four weeks.

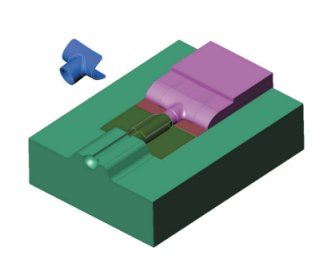

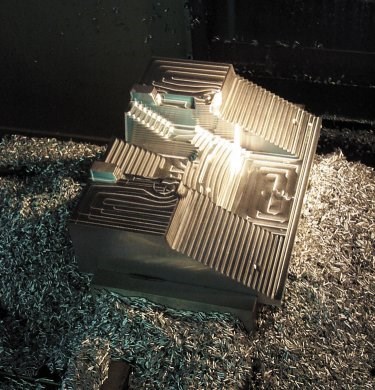

According to CAD/CAM designer Brian Evans, wax injection molds are the only way to create precise castings that are needed in certain industries. "These molds are created to tolerances of approximately .0005 inches," he explains. "From this, the wax model is created, which is the pattern that will be used for the final casting." Additionally, the company does mold and tool design, fixture design and construction, and various three- through five-axis machining.

Zeroing in on a niche - along with careful quoting, efficient design and solid modeling, efficient toolpath programming and top-notch computer CAD/CAM software - has resulted in Peterboro Tool's ability to thrive for more than 30 years. Evans also attributes the company's success to "skilled employees, a down-to-earth casual environment, and openness and communication among employees and customers."

A Good Start

Kenneth Rogers, Kenneth Stockwell and Jim Poodiack started the company in 1972. All three of them were moldmakers with experience in management and tool engineering at a large casting company in New Hampshire. According to Stockwell, the trio felt the time was right to go into business for themselves. Evans adds that the company's initial purpose was to "provide quality, fair prices, on-time delivery and honest work when manufacturing wax injection molds" for the investment casting industry.

"Our company does not operate with a head for each department, or a strict set of guidelines like many 'traditional' companies," Evans notes. "But we allow each employee - based on their experience and expertise - to take a design concept for a job and see it through from start to finish. If an employee wishes to change a certain aspect of the original design to make the job quicker or easier, he will usually get the okay to do so, without having to wait for an answer to make its way through the management chain. Each person has their own niche - whether it is speed, holding tight tolerances or troubleshooting. Our employees stay with us for long periods of time, as it takes time to learn and perfect their trade. And - because we are the first link in the chain of producing a product - there is always a fairly steady workflow that never totally dries up. Thus, employees are not let go, especially if time and money have already been invested in them.

"With 12 employees, we may seem too small and possibly incapable of producing complicated or intricate work, but because of our up-to-date technology in machinery, computers and software, we can be much more efficient than many other larger shops," Evans continues. "We also operate on a personal, low-pressure level with our customers - offering them a place where they send their work with confidence and discuss their needs or opinions whenever is most convenient to them."

Staying Focused

According to Evans, very few companies in the United States are focused on one aspect of a "unique-in-itself" industry, and because of this focus and vision, Peterboro has been able to stay ahead of its competition over the years. "We attribute our jump to CAD/CAM and CNC in 1990 to our competitiveness today," Evans notes. "That and automation, which comprises approximately 50 percent of our process. Most of our automation is computer and software procedures such as a full mold design finished as a solid model, which ensures that after individual die components are cut via CNC, all of the pieces fit together, saving handwork, plugging, etc. By using technology to do the time-consuming, repetitive and error-prone aspects, it leaves more time for the employees to work in a more economic fashion."

Peterboro's one worry in a slow economy is making enough profit to stay in business, as well as invest in new areas should the need arise, Evans notes. "The typical way to address this would be to increase prices, but that would be unwise, as there are many other shops - both domestic and foreign - that would gladly underquote a project in order to keep busy, even if it meant a slight loss for that particular job," he explains. "So, in order to combat this we are constantly seeking new ways to stay lean, without cutting corners in quality and workmanship. Our goal is to provide our customers with a place and people where they can confidently send their work to for the best price, quality and delivery."

Controlled growth is another one of the company's goals. "We plan to grow slowly as we always have, making sure each move is a step forward," Evans comments. "New CAD and CAM software upgrades and CNC equipment will help further our commitment to staying one step ahead. We are constantly researching new technologies and developments in software, computers and CNC machinery, and whenever a particular technology offers a benefit that would drastically help us better our leadtimes and quality, and the affordability is there, we will try to incorporate it into our business."

Related Content

U.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreFAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreVIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

Read MoreMMT Chats: A More Modern NPE “Made for You”

The Plastics Industry Association is making NPE 2024 a “can’t miss”’ experience with more of everything – education, exhibitors and networking! The PLASTICS Industry Association Chief Operating Officer Glenn Anderson and Director of Trade Show Marketing Damaris Piraino share what’s in store for attendees of next year’s May 6-10, 2024 in Orlando, Florida.

Read MoreRead Next

Good Investment Casting

An increasing number of shops that make metal parts that are intricate, require extensive machining or are produced repetitively or in limited quantities, are finding that investment casting is the ideal solution.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More