Moldmaking Gets Wyrd—and Amazing—with All-Digital Sculpting

By early 2012, when the price of white metal had increased 80 percent over the past two years— eating into revenues and margins—Wyrd was forced to rethink its approach. Ghost Studio, a Longmont CO-based product design firm, and Geomagic, maker of 3D software solutions from scan to design to manufacturing, soon presented Wyrd with a smarter way.

In the gaming industry, it pays to be weird—literally. Wyrd Miniatures is a 7-year old company providing character skirmish games, also known as “war games.” Unlike computer games, these are figurine-based board games centered around a storyline and families of miniature game pieces. Hobbyists assemble and paint the miniatures and then play battle games with friends and in tournaments. It’s an estimated $1B worldwide market dominated by two giants—and an additional 50 or so smaller companies—who sell in specialty stores, conventions and meet-ups like GenCon, but primarily on the Web. Young, small game companies like Wyrd have to be nimble, different and frankly a little weird to stand out.

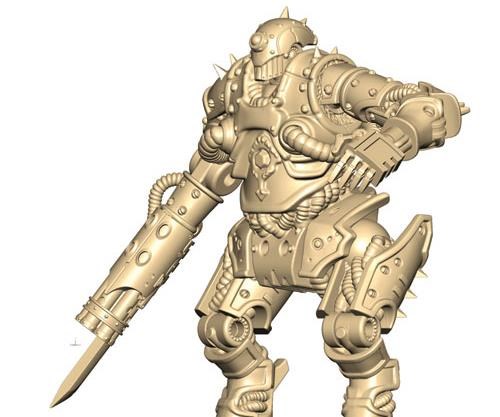

Wyrd gets its edge from offering characters of such intense detailing and compelling storylines that they leap out across the display table on a convention floor or on the Internet to make the buyer choose them. For example its hit character skirmish game “Malifaux” includes 200 fantastical creatures, half human, half mythic, with highly sculptural and organic shapes and detail in a 22mm to 78 mm form factor. The detail makes all the difference between a game’s appeal and marketability.

But detail comes with a cost, especially for moldmaking. Since its founding Wyrd manufactured figurines in white metal because at the time, manufacturing processes dictated that only white metal figurines of that small 22mm size could retain such product detailing in the molds and tooling. The detailing also meant Wyrd designed initial concepts by hand-carving models of miniature—which was great, except when a change was required, changing the model meant starting with a new lump of clay.

Rethinking the Approach

By early 2012, when the price of white metal had increased 80 percent over the past two years— eating into revenues and margins—Wyrd was forced to rethink its approach.

Ghost Studio, a Longmont CO-based product design firm, and Geomagic, maker of 3D software solutions from scan to design to manufacturing, soon presented Wyrd with a smarter way. Ghost had extensive experience in digital manufacturing innovations and convinced Wyrd that even its highly inventive figures could be manufactured faithfully, with all design intent captured, with plastic injection molding processes. Furthermore Ghost had experience with a special trick piece of software to drive the entire process digitally.

That software was the Freeform® 3D modeling solution from Geomagic. In the next six weeks, Wyrd and Ghost Studio collaborated to revamp Wyrd’s workflow into an all-digital process, starting with digital sculpting, moving on through to digital moldmaking, and finally to digital production tooling made via STL/CNC milling.

With the Gen Con 2012 show—the largest US venue for character skirmish game companies, driving deadlines—Wyrd and Ghost Studio proceeded to digitally sculpt 40 miniatures for six new box sets, then used the digital designs as the basis of a streamlined digital manufacturing process that moves from art to production tooling via STL milling.

The move to digital sculpting with Freeform allowed Wyrd to deliver exceptional detail that was previously not possible to achieve in metal figurines—detail that exactly reproduces and in some cases exceeds the detail in the original line art, even for intricately detailed miniatures such as Lazarus and the Archer.

“Gen Con basically proved to us that we did the right thing in the move to plastic,” says Nathan Caroland, co-owner of Wyrd Miniatures, based in Kennesaw, GA. "We had customers nearly salivating at our booth. The digital sculpting done with Freeform, when paired with the capabilities of plastic, lets our miniatures retain all the details and animation of the original artwork, and really made our miniatures stand out.

“Our customers were really excited about the new poses and the intricacies of our new releases. By going all digital we raised the bar on detail as well as quality through Freeform," Caroland says.

Benefits of Going Digital

Embracing digital sculpting with Freeform also allowed Wyrd to get to market at least one-third faster and produce miniatures in plastic, while avoiding the approximately white metal cost increase and lowering shipment costs, since plastic is lighter-weight. The design file created in the Freeform solution now serves as the foundation of a streamlined, far more accurate plastic injection moldmaking and manufacturing process. Resulting product details are crisper, surface finishes are smoother, and the plastic allows better paint adherence.

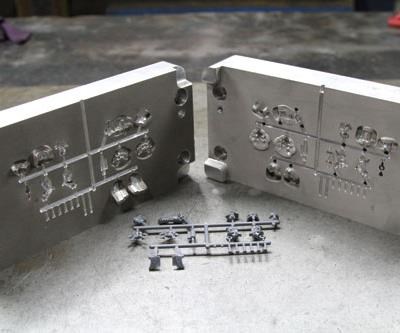

Freeform also allowed Ghost Studio to create molds directly from the final design file, instead of the traditional need for a pantograph process to transcribe a prototype of the final process as the starting point for defining parting lines and mold splits. In addition to being a 3D modeling platform for designing organic shaped products, Freeform has extensive design for manufacturability feature set, including draft evaluation and correction utilities.

Mold-split and parting line decisions are pivotal to the aesthetics, as well as to manufacturability. Since mold splits potentially could interrupt characters' features or introduce potential breakage, defining good mold splits was critical to Wyrd's intricate miniatures.

Freeform's Draft Analysis tools—including automatic draft fixing and dynamic analysis tools that visualize potential mold draft issues on screen while the designer is adjusting a model—allowed Ghost Studios' team to play with potential mold pulls on screen, identify potential undercuts, and quickly fix problems before expensive machining was performed.

Being digitally driven also meant that if a change was required, for example to adjust a spot in the mold where plastic material was shrinking due to improper cooling within the cavity—it could be done on the digital model in a matter of minutes.

Precision Results

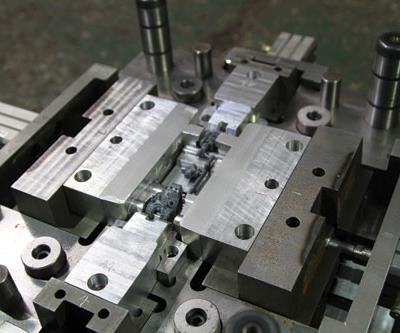

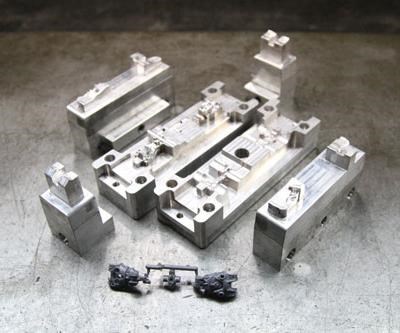

What resulted for Wyrd was such a precision fit of the molds that it all but eliminated the seam that typically appears as plastic flashing in between mold halves. Wyrd has also streamlined processes at the warehouse for inspection and quality control, since the molds fit so precisely there was virtually no flashing to be removed manually prior to shipment to customers.

Once draft has been created and pull directions defined, the parts are exported as STL files goes into CopyCad, a Delcam program that defines parting lines and mold splits, dividing and defining an A side and a B side. Those parts are then shelled, arranged as a family mold with multiple figures united within a runner, at either 4 x 6 inch or 8 x 6 sizes depending on the size of parts. The requisite ¼ inch shut off area in between cavities can be placed to assure there is no flashing.

Next gates are added for plastic flows into each cavity, and the entire digital file goes into DelCam’s PowerMill where actual toolpath calculated for successively smaller drills used by CNC machines. A test shot (T1) is produced, the resulting shot is checked to make sure plastic hasn’t shrunk and any requisite corrections are made. The test process runs again, another test shot 2 (T2) is produced, any required tweaks are made to the Freeform digital file and finally when the precision fit of the molds is just right, the final Wyrd miniatures go into production.

Just several years ago it took between 90 and 120 days to move from design to manufactured part for a typical toy—and that’s just one part. Today using Freeform, Wyrd is moving from design to finished parts for 5 characters on a sprue in far less time, and achieving levels of detail that were difficult if not impossible to obtain in the past.

When creating both design files and molds for toy and miniatures—markets where the plastic injection moldmaking process must retain intense levels of product detail—it’s the ability to achieve such detail as Wyrd achieved, while also enabling a vastly improved manufacturing workflow, that is a genuine competitive differentiator.

For More Information:

Geomagic

(800) 691-1839

geomagic.com

Delcam

(877) 335-2261

delcam.com

Wyrd Miniatures

wyrd-games.net/

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

A Perfect Tool for Modeling a Mold with Multiple Curves and Flowing Shapes

Design-intent modeling greatly reduces the time required to transform a bottle or mold into an editable CAD model for further design and manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)