How to Move Closer to Unattended, 24/7, Lights Out Machining

A look at why there is more to lights out machining than running unattended.

Manufacturers such as moldmakers are always looking for a way to gain a competitive edge—such as reducing manufacturing costs or shortening part delivery times. Implementing some form of lights out machining can help you move closer to both of those goals; however, there is more to lights out machining than just running unattended. The goal of this article is to provide some tips to help get you closer to unattended, 24/7, lights out machining.

Invest in Tooling and Technology

When running parts unattended, you will need to invest in multiple copies of the same cutter. You won’t have a person there to change inserts on the cutters, instead you will automatically change the cutters after a set time or distance. This is usually accomplished via functions in your CAM software package—either during programming or post processing of the cutterpaths.

Use automatic tool setting systems—such as lasers—for controlling tool lengths automatically. These systems also check the run out on the tools and can check for excessive insert wear after the tool is used for milling. For safety, these systems can be set up to stop the machining process if the tool setting systems detects problems, and then provide immediate notification of the error.

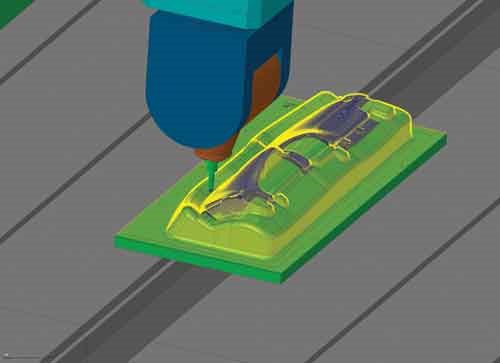

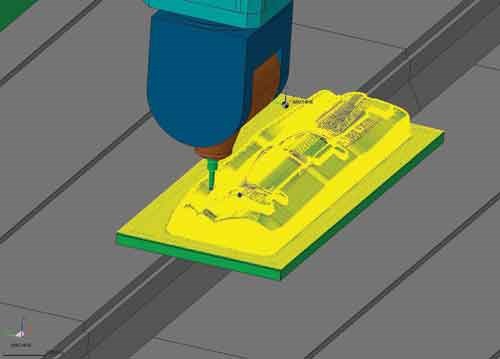

In practicality, most machinists are more comfortable running semi finishing and finishing cutter paths unattended rather than roughing cutter paths. Often this is because of the sheer number of tool and insert changes necessary during roughing operations. Other factors are also involved—including having a person to assist the milling machine with chip evacuation.

Investing in quick change pallets may allow you to rough some parts during the day, and change the pallet for finishing cuts on the parts that are roughed and ready for overnight machining. Then the next day, continue where you left off on roughing the other parts.

Get a Superior Finish

When running parts overnight, use your CAM software’s estimate of mill run time. Often when running overnight, the machine will finish before the morning shift starts. If this is the case and you cannot add other parts to mill, you may instead choose to recalculate the cutter paths with a finer stepover. This will not only provide smaller cusps on the finished part—requiring less polishing later on—but also reduce tool wear and generate less heat overall.

Use Advanced CAM Collision Checking Features

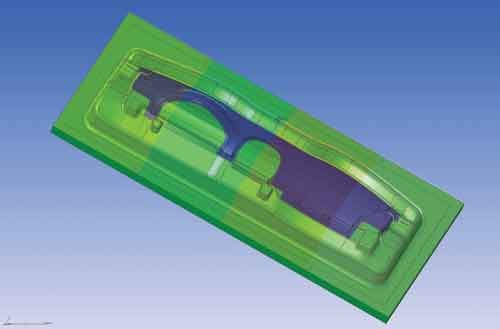

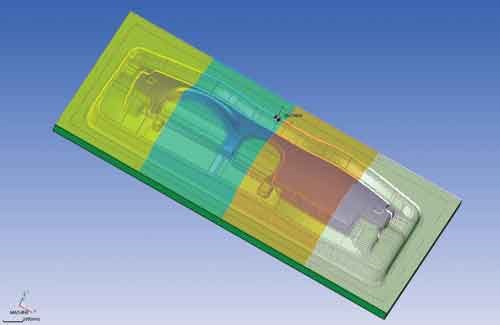

CAM software must provide reliable collision-free cutter paths all the time, but this is especially essential for unattended machining. Many CAM software products provide functionality for collision checking the tool, spindle and mill geometry with the part. Some will do this collision checking in a batch calculation. Performing this collision checking can verify the integrity of the cutter path, and provide the confidence in running them unattended.

Multi Part Machining

Quick change pallets can also assist with multiple part machining. This is when there are several small details, which can be mounted onto a pallet and all of them machined overnight.

Not only does multi part machining require some investment in equipment for mounting and fixturing the parts, but it may also require special functionality in your CAM system to bring the separate programmed parts into the database. These individual CAD/CAM files need to be inserted into one assembly program, tool changes optimized and locations of tool origins for individual components set.

Get Connected

In the age of the internet, texting and smart phones, you can practically have a virtual employee watching the machine. Internet-enabled cameras can be set up on the machines, allowing those with access the ability to see the machine milling unattended in real time. This allows for boosting the confidence in the process. Also, alarms can be set up to automatically send an email or text message to designated persons should there be a fault or error in machining.

Shops handle this differently. Sometimes just the owners or managers get these notifications. Other shops have key employees they trust to be on call should they get error messages during the evening or night. Obviously, the faster you can react to problems that do arise, the better the process works.

Manufacturing Resource Planning

It can be difficult to plan your work around many of these tips. Using software products for shop management and scheduling—such as found in MRP (Manufacturing Resource Planning) and P (Enterprise Resource Planning) products—can manage the workflows to maximize the benefits of unattended machining.

Many of these products can be accessed remotely—for authorized users—so that managers can check the workload and scheduling at any time, from any location.

Summary

Running lights out, unattended machining can reduce costs as well as shorten leadtimes on milling components. Moving to this step with confidence requires an investment in tooling, technology, software and connectivity.

Related Content

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreRead Next

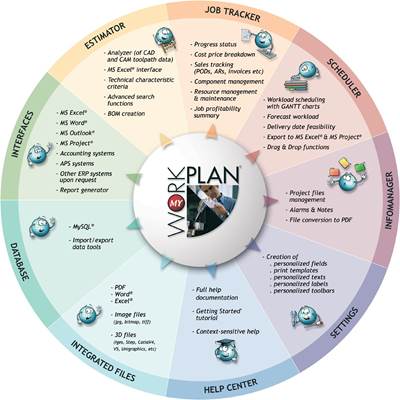

Toolmaker Benefits from ERP Software

WorkPLAN Enterprise ERP software integrates with SAP® for greater transparency at German toolmaker HARTING Applied Technologies. The company has 15 WorkPLAN Enterprise workstations in a Citrix terminal server environment enabling managers, controllers, technicians and the sales personnel to have access to relevant data on the central WorkPLAN Enterprise system.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More