Mold shops that recognize the potential of technology and equipment, and prioritize both accuracy and productivity will increase their competitiveness in the marketplace. The key is utilizing machines that are engineered to reduce the time-consuming elements of mold manufacturing, increase mold quality, enhance accuracy and eliminate opportunities for human error.

The mold-building process addresses a challenging combination of machining tolerances, further complicated by tedious workpiece setups that enable the machine to interact with the workpiece more precisely across machining and drilling steps.

Machines designed to handle specific moldmaking challenges—such as increasing throughput by eliminating many of the major time-intensive elements involved in creating a mold—are an optimal solution for mold manufacturers looking to gain an advantage. These machines have features that reduce the need for costly fixtures and extended changeovers, and enable a single setup for several machining processes while allowing operations to be performed on all four sides of a workpiece.

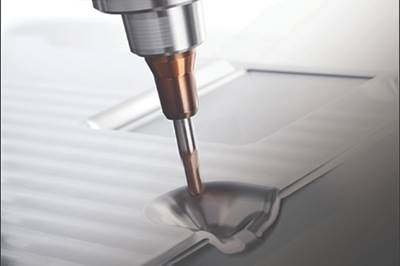

A mold on such a machine can be produced using a roughed-out workpiece that is clamped to the table with modular locating components. The part is milled on four sides and drilled at very high feed rates using high-performance gun drills and BTA tools. With the same setup and fixturing, compound angle machining, intersecting bores, pocketing and complex surface milling can be completed accurately and efficiently. Probing for critical features can then be performed. The mold manufacturer saves days in production time.

A capable machine also will meet the high tolerance demands of complex mold profiles. Features contributing to this include a rigid B-axis table that can handle heavy

workpieces as well as high moment capacity. Another essential feature is a headstock carrying milling and drilling spindles that can tilt on an A axis without a loss in rigidity, and allows B-axis rotation at extreme angles and larger than typical travels. All of this leads to the elimination of tedious changeover work, which can save valuable time and effort that can then be applied to using advanced technology and creating better molds.

Machines that combine a range of machining and drilling operations, including high-performance milling and deep-hole drilling, can further increase efficiency. These feature multi-axis positioning and are equipped with capable headstocks with geared transmissions, and 50-taper spindles. A deep-hole drilling headstock capable of conventional gundrilling as well as BTA high-performance drilling will be five-to-seven-times faster than gundrilling alone to further increase productivity and maintain accuracy.

Highly productive machines take advantage of opportunities for automating the machining process as well, and they are extremely accurate in dynamic situations regardless of axis orientation. These machines typically are outfitted with several beneficial options, such as glass scales and direct-feedback angular encoders. They also are able to take advantage of volumetric compensation with a standard contouring control. Furthermore, workpiece probing, laser presetting and large-capacity automatic toolchangers allow unattended operation with greater versatility than previously possible. In addition, process feedback further improves a machine’s capabilities by allowing tooling to be pushed to the limit with the assurance of automatic cycle interruption before something catastrophic occurs.

Summary

The seamless integration of multiple technologies and operations in a single machine can be advantageous. Parametric 3D programming, sophisticated post processing, tool management and on-machine verification are common in more and more shops as the technology becomes affordable. Capable machines are engineered to optimize this technology, and this in turn drastically improves the process that competitive mold manufacturers use to succeed.

View Drilling and Milling for Mold Applications Video Here.

.jpg;maxWidth=970;quality=90)